General Maintenance and Troubleshooting

SM 6495, Rev. 7, December 2008 2-17

2.5.3. Vertical Adjustment

2.5.3.1. Vertical Adjustment Using Spring Scales

Raise the gate to the vertical position. Attach the spring scale at the specified distance (x) according to

Table 2-1. This distance is measured from the mechanical output shaft and up the arm to where the

spring scale is to be attached. Once scale is in place, release arm by loosening the gold nut on the

terminal board. To adjust, loosen hardware and slide counterweights back and forth (this would be up

and down if the arm were down).

2.5.3.2. Vertical Adjustment Using Torque Wrench

Apply an appropriate torque wrench (J039000-0115 supplied in optional torque wrench kit X467000-

03) to the motor shaft located in the lower-left corner of inside housing. Release arm by loosening the

gold nut on the terminal board. To adjust, loosen hardware and slide counterweights back and forth

(this would be up and down if the arm were down). Refer to Table 2-1 for appropriate measurements.

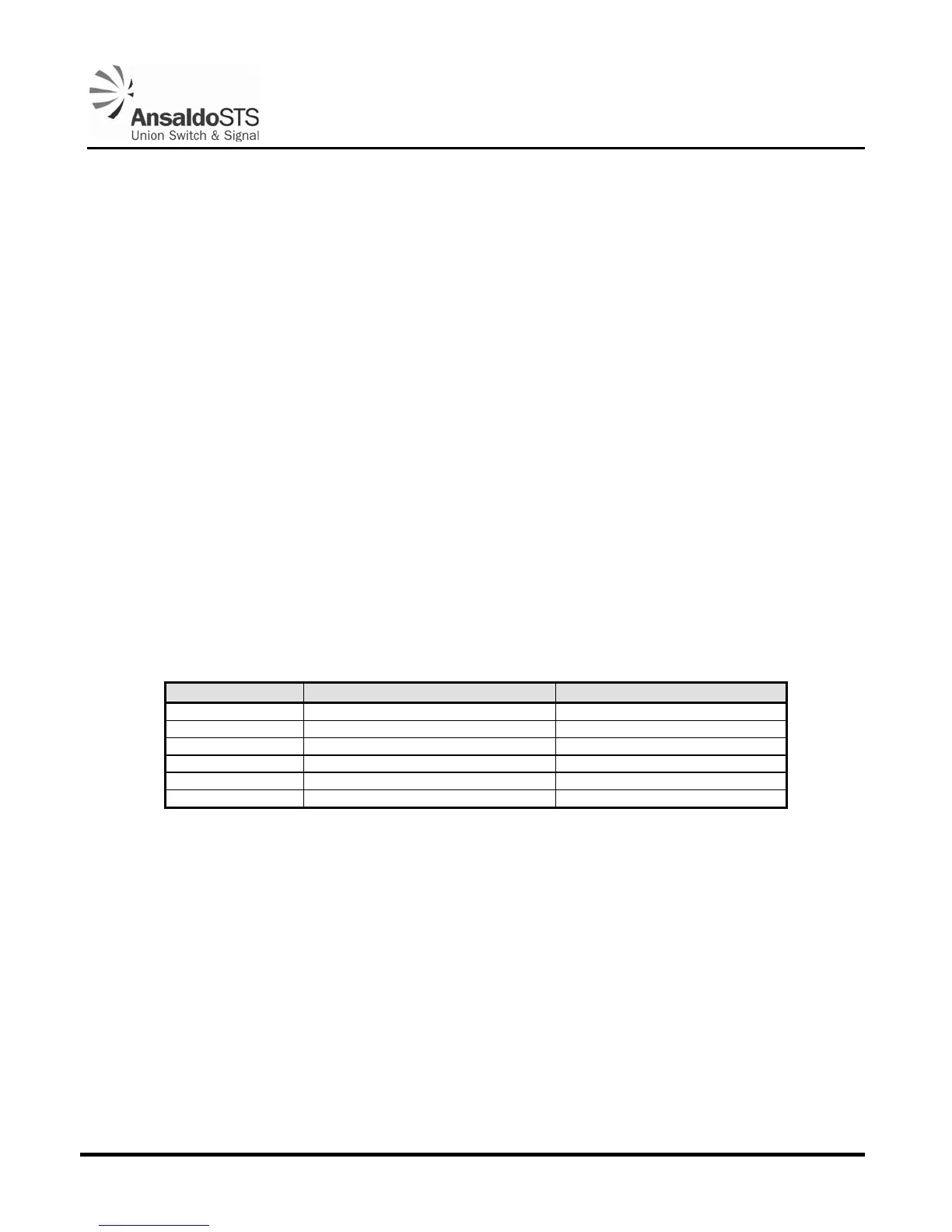

2.6. Cam Adjustment

The cams should be rotated so that the appropriate contacts are closed as indicated in Table 2-3. Use a

3/16” T-handle Allen wrench provided with the gate mechanism to loosen one of the two cam screws

to be adjusted.

Table 2-3 - Cam Adjustment

Contact No. Closed (Degrees)* Function

1 0-89 Motor Control Relay

2 Not used for contact set.

3** 46-93 Motor Down

4 5-93 Bell

5 0-5 Gate Down Indicator

6 83-90 Flashing light

* Ninety degrees-gate in vertical position.

** When adjusting cams for the Sidewalk Gate Mechanism, it may be necessary to adjust the #3 cam in order

to properly drive the gate arm down.

In a typical installation, the No. 1 cam will have to be rotated to determine precisely where the arm

rests in the vertical position. Ensure that the side-to side cam adjustment is centered with the contact

assembly so that the contact assembly side walls do not touch the cams. Refer to

Figure 2-9.

After the cams are properly positioned, begin tightening the clamping screws until each cam begins to

fit securely to the shaft. Turn the screw approximately 1-1/2 more turns to obtain torque. The Heel

Spring force on the cams is 1-1/2 to 4 pounds on No. 1 spring, and 1/2 to 3 pounds on springs 3-6. Do

not allow gaps between each cam half.

Loading...

Loading...