Manual, F/T Sensor, Ethernet Axia

Document #9610-05-Ethernet Axia-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

87

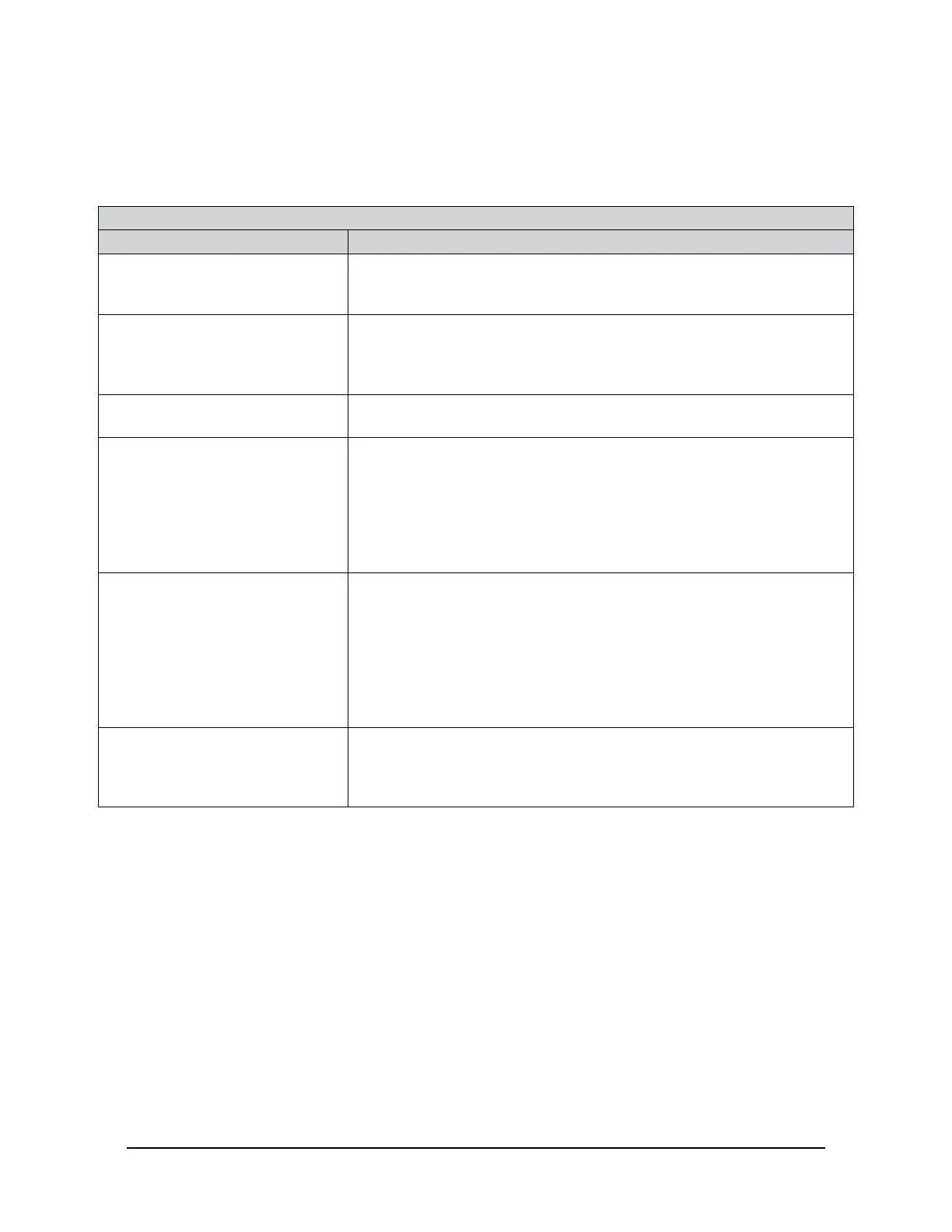

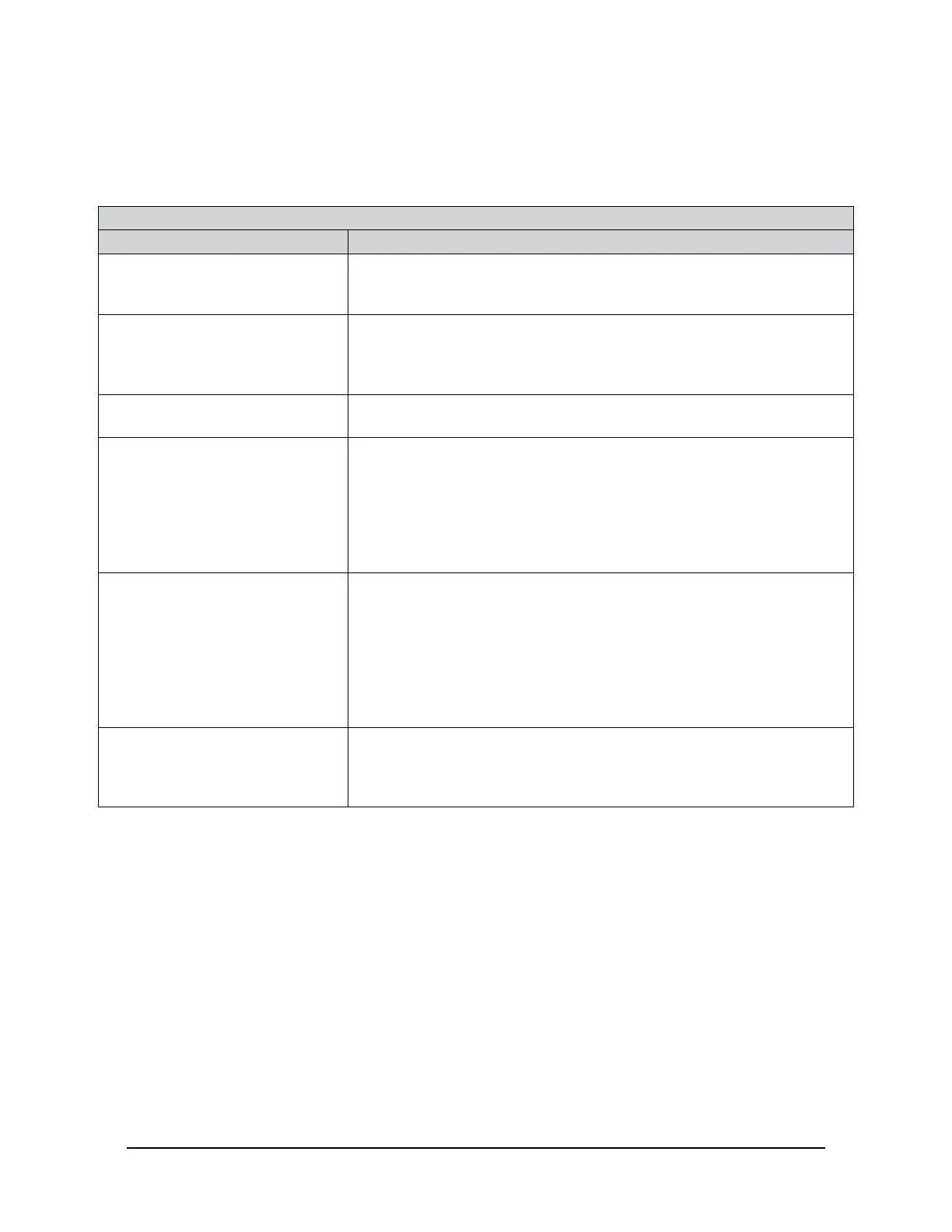

14.5 Errors with Force and Torque Readings

Incorrect data from the sensor’s strain gages can cause errors in force/torque readings. Listed in the

following table are the basic conditions of incorrect data. Use this table to troubleshoot a problem. In most

cases, problems can be better identied while looking at the raw strain gage data, displayed on the Snapshot

page. See Section6.2—SnapshotPage(rundata.htm) for more details.

Table 14.5—Errors with Force and Torque Readings

Symptom Cause and Resolution

The sensor is not streaming

measurement data to the

customer devices.

Verify the sensor is correctly installed. Ensure the robot mounting and

tool adapter plates are installed on the proper side of the sensor. Refer

to Section 3—Installation for more information.

Either the “Force/Torque Out of

Range” or the “Gage Out Range”

bit is set (refer to Section 4.8—

Status Code),

The sensor is reporting that it is no longer within the calibrated range

and may experience inaccuracy and reduced life.

The “Broken Gage Bit” is set (refer

to Section 4.8—Status Code).

An electrical failure has potentially occurred inside the sensor. The

sensor must be returned to ATI for diagnosis.

Noise

Jumpsinforcetorquedatareadings(withthesensorunloaded)greater

than 0.05% of full scale counts is abnormal. Noise can be caused by

mechanical vibrations and electrical disturbances, possibly from a poor

ground. Noise can also indicate component failure within the system.

Make sure that the DC supply voltage for the Axia sensor has little

to no noise superimposed. The sensor should be grounded through

installation construction. See Section 14.6—Reducing Noise.

Drift

After a load is removed or applied, the raw gage reading does not

stabilize but continues to increase or decrease. A shift in the raw gage

reading is observed more easily in the resolved data mode using the

bias command. Some drift from a change in temperature or mechanical

coupling is normal. Mechanical coupling occurs when a tool plate

contacts the sensor body, for example, debris between the tool adapter

plate and the sensor body or in applications such as hoses and wires

attached to a tool.

Hysteresis

When the sensor is loaded and then unloaded, gage readings do not

return quickly and completely to their original readings. Hysteresis is

causedbymechanicalcoupling(explainedinDriftsection)orinternal

failure.

14.6 Reducing Noise

14.6.1 Mechanical Vibration

In many cases, perceived noise is actually a real uctuation of force and/or torque, caused by

vibrations in the tooling or the robot arm. The Ethernet Axia sensor offers digital low-pass lters

that can dampen frequencies above a certain threshold. If digital low-pass lters are insufcient, a

digital lter may be added to the application software.

14.6.2 Electrical Interference

To reduce the effects of electrical noise on the sensor, do the following:

• If interference by motors or other noise-generating equipment is observed, check the sensor’s

ground connections.

• If sufcient grounding is not possible or does not reduce noise, consider using the sensor’s

digital low-pass lters.

• Verify the power supply is Class 1, which has an earth ground connection.

Loading...

Loading...