Manual, F/T Sensor, Ethernet Axia

Document #9610-05-Ethernet Axia-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 • www.ati-ia.com

89

14.8.4 Avoid Logging the Host to a Company Network

Being logged onto a network requires the periodic access to the Ethernet interface by processes

other than the measurement application and can lead to loss of UDP packages.

14.8.5 Use a Dedicated Network

Placing the sensor on a dedicated Ethernet network with no other devices on the network, other

than the host computer, removes data collisions and gives the best network performance.

15. Specications

The requirements for the Ethernet Axia sensor interface are covered in the following sections.

15.1 Environmental Conditions

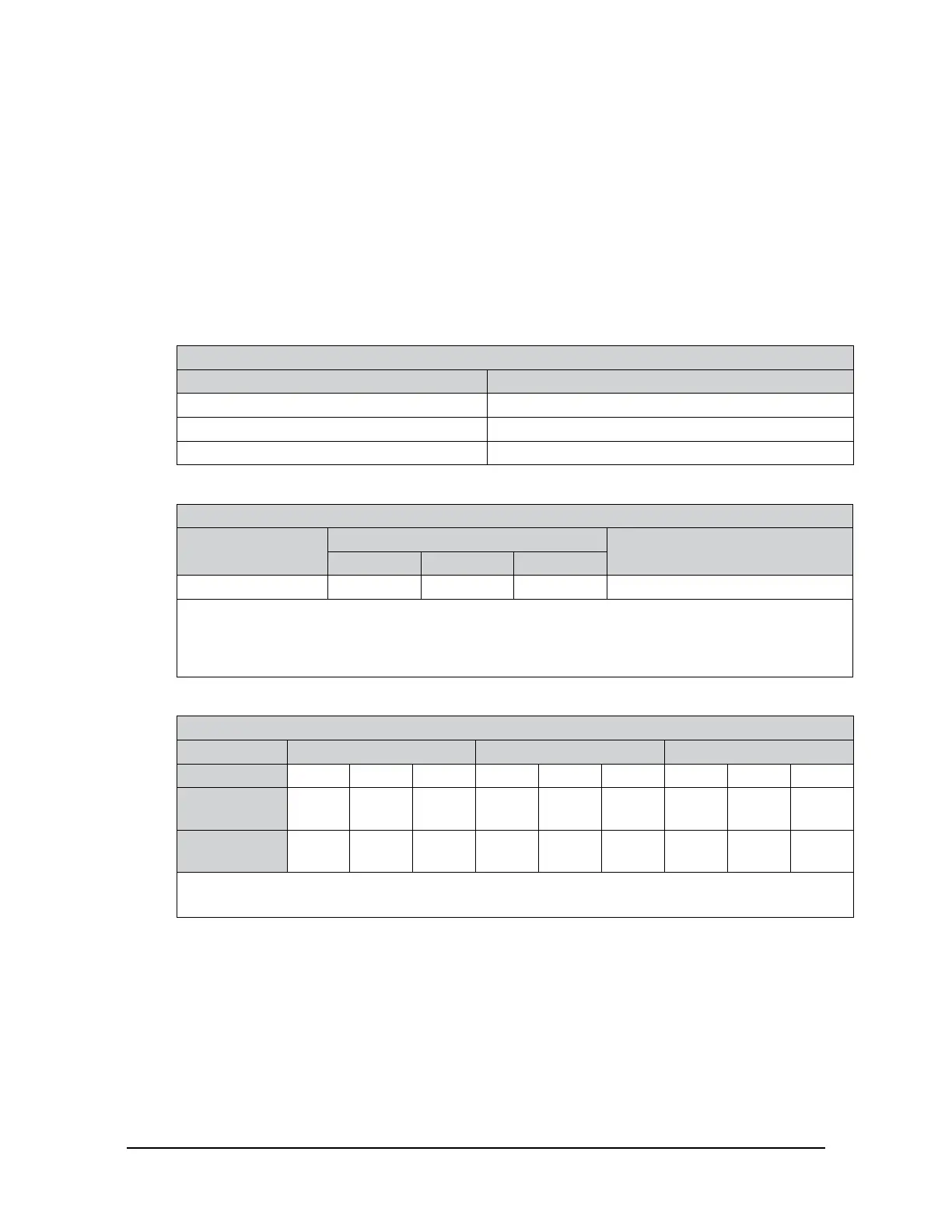

Table 15.1—Environmental Conditions

Parameter Value

Storage Temperature, °C -20 to +85

Operating Temperature, °C 0 to +65

Relative Humidity <95%,non-condensing

15.2 ElectricalSpecications

Table 15.2—Power Supply

1

Power Source

Voltage

Maximum Power Consumption

Minimum Nominal Maximum

DC Power 12 V 24 V 30 V 1.5 W

Notes:

1. The power supply input is reverse polarity protected. If the power and ground to the power supply

inputs are plugged in reverse, then the reverse polarity protection stops the incorrectly wired supply

input from damaging or powering on the sensor.

15.3 Calibration Ranges

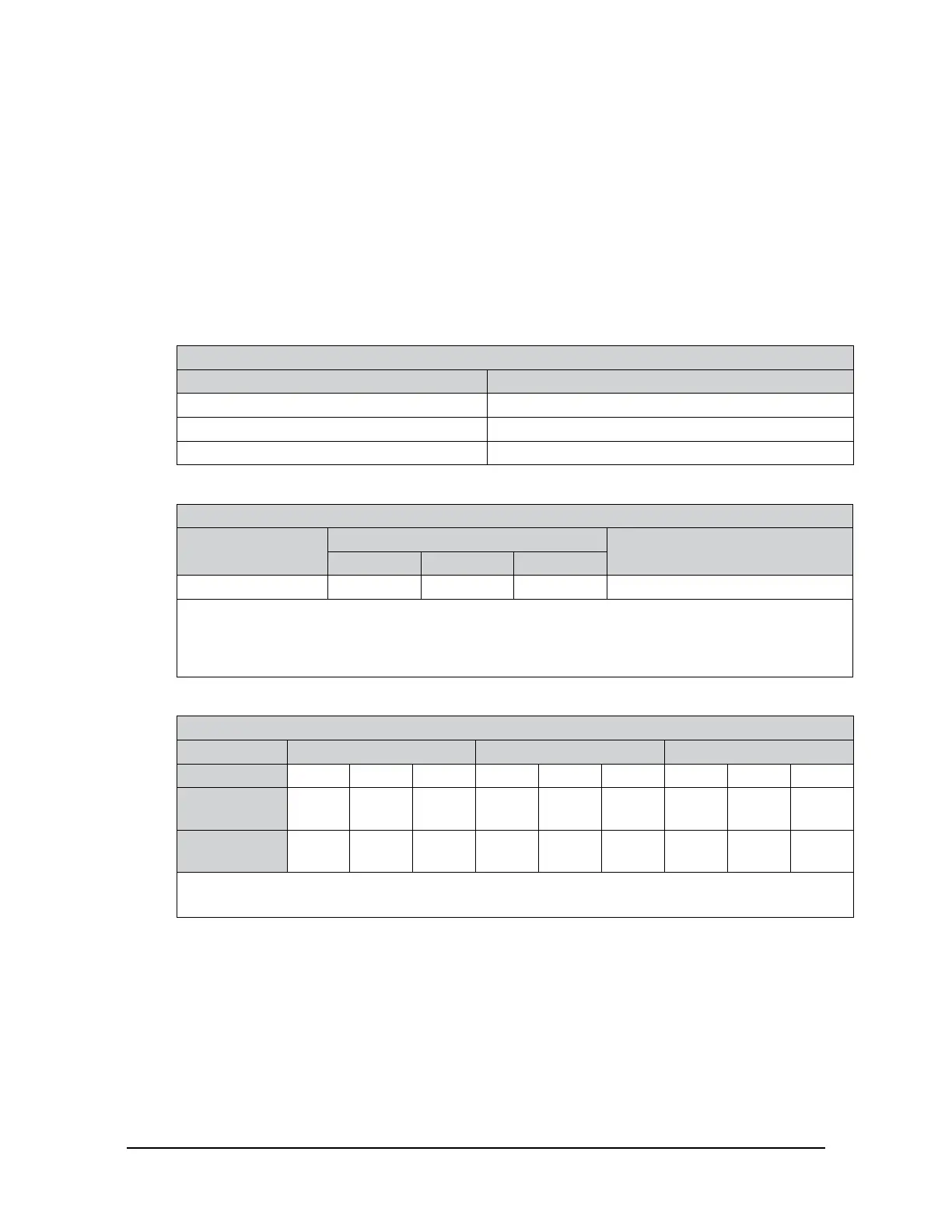

Table 15.3—Calibration Range 0 and Calibration Range 1

Model Axia80-M8 Axia80-M20 Axia80-M50

Parameter Fxy Fz Txyz Fxy Fz Txyz Fxy Fz Txyz

Calibration

Range 0

150 N 470 N 8 Nm 500 N 900 N 20 Nm 1200 N 2000 N 50 Nm

Calibration

Range 1

75 N 235 N 4 Nm 200 N 360 N 8 Nm 480 N 800 N 20 Nm

Notes:

1. Each Ethernet Axia80 sensor is calibrated with both of these calibration ranges.

Loading...

Loading...