F/T DAQ Installation and Operation Manual

Document #9610-05-1017-06

ATI Industrial Automation, 1031 Goodworth Drive, Apex, NC 27539 USA +1-919-772-0115 www.ati-ia.com

36

7.2.2 Nano25

En

lish

US

Metric

SI

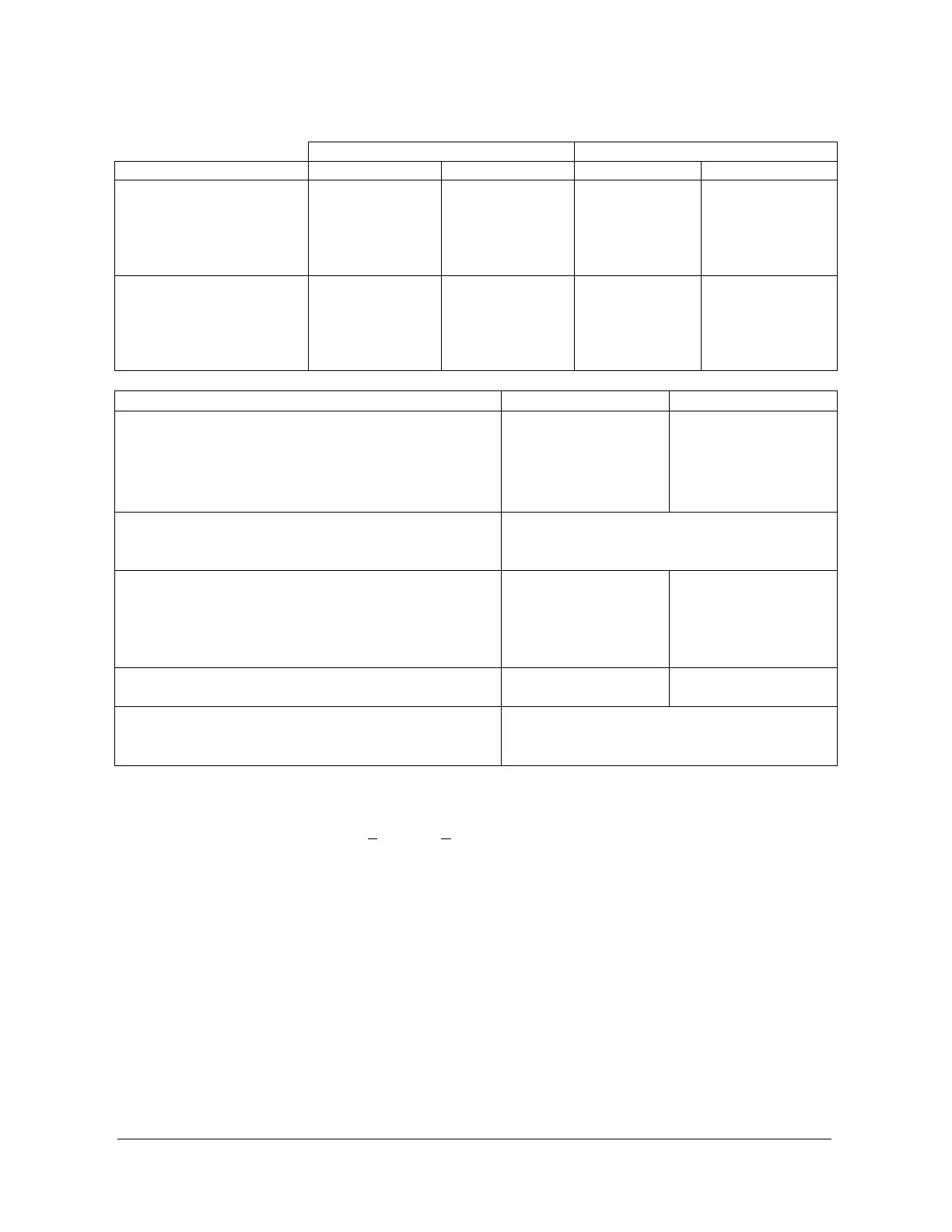

Calibration US-25-25 US-50-50 SI-125-3 SI-250-6

Rated Sensin

Ran

es

Fx, Fy ±25 lb ±50 lb ±125 N ±250 N

Fz ±100 lb ±200 lb ±500 N ±1000 N

Tx, Ty ±25 in-lb ±50 in-lb ±3 Nm ±6 Nm

Tz ±25 in-lb ±30 in-lb ±3 Nm ±3.4 Nm

Resolution*

Fx, Fy 1/896 lb 1/448 lb 1/192 N 1/96 N

Fz 3/896 lb 3/448 lb 1/64 N 1/32 N

Tx, Ty, 1/640 in-lb 1/320 in-lb 1/5280 Nm 1/2640 Nm

Tz 1/1280 in-lb 1/640 in-lb 1/10560 Nm 1/5280 Nm

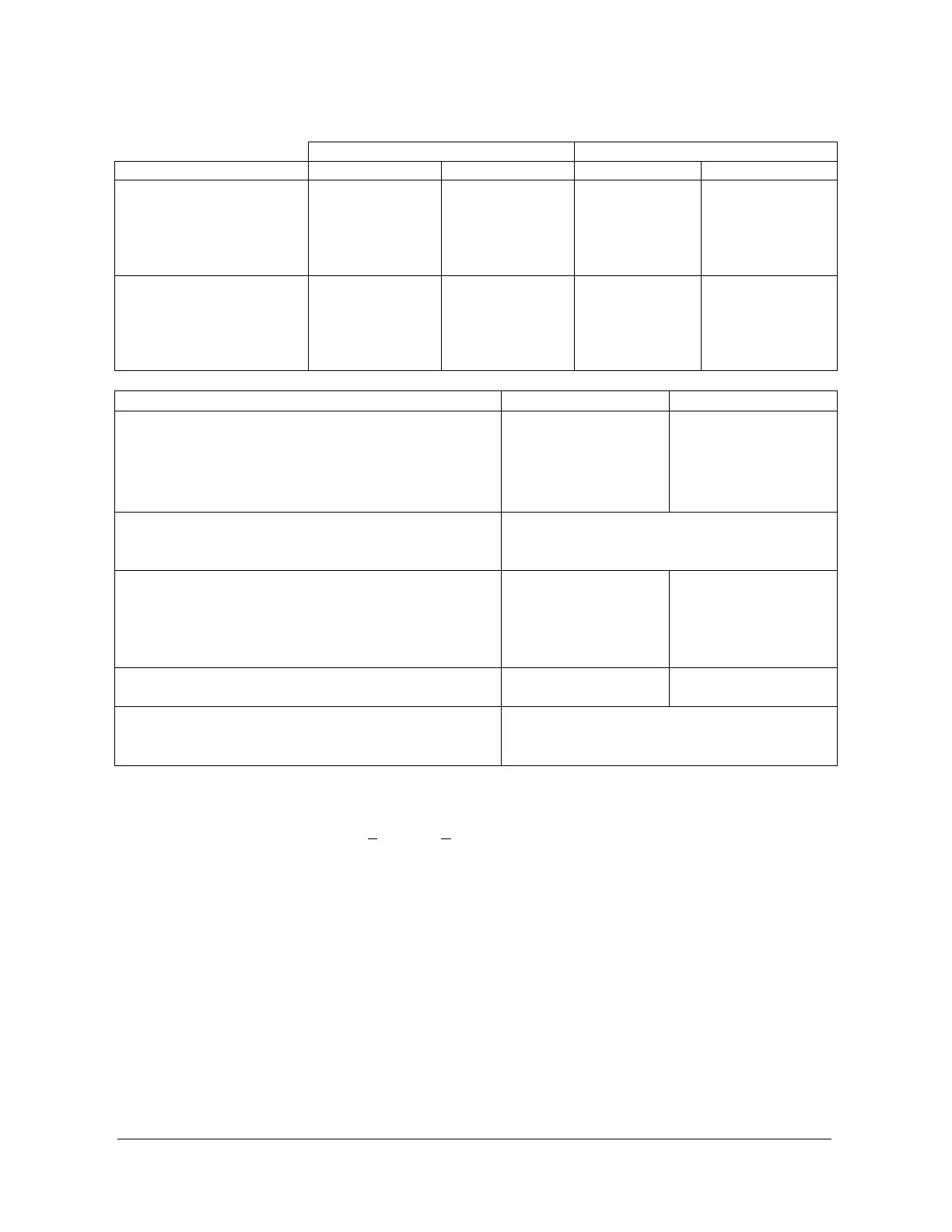

Physical Properties US Metric

Stiffness (Calculated)

X-axis and Y-axis force (Kx, Ky)

300×10

3

lb/in 53×10

6

N/m

Z-axis force (Kz)

630×10

3

lb/in 110×10

6

N/m

X-axis and Y-axis torque (Ktx, Kty)

57×10

3

in-lb/rad

6440 Nm/rad

Z-axis torque (Ktz)

82×10

3

in-lb/rad

9260 Nm/rad

Resonant Frequency (Measured)

Fx, Fy, Tz 3.6 kHz

Fz, Tx, Ty 3.8 kHz

Maximum Single-axis Load

Fx, Fy ±520 lb ±2300 N

Fz ±1400 lb ±6300 N

Tx, Ty ±310 in-lb ±35 Nm

Tz ±560 in-lb ±63 Nm

Weight

Transducer with standard plates 0.14 lb 65 g

Material

Transducer Hardened Stainless Steel

Mounting and tool adaptors Hardened Stainless Steel

*Resolutions are typical for a 16-bit data acquisition system.

Note: Applying moments beyond +

30 in-lb (+3.4Nm) in Tz can cause hysteresis and permanent zero-

point change in this transducer

Loading...

Loading...