F/T DAQ Installation and Operation Manual

Document #9610-05-1017-06

ATI Industrial Automation, 1031 Goodworth Drive, Apex, NC 27539 USA +1-919-772-0115 www.ati-ia.com

30

The internal structure of the transducers can become clogged with particles and will become

uncalibrated or even damaged.

Periodic calibration of the transducer and DAQ card is required to maintain traceability to

national standards. Follow any applicable ISO-9000-type standards for calibration. ATI

Industrial Automation recommends annual recalibrations, especially for applications that

frequently cycle the loads applied to the transducer.

6.4 A Word about Resolution

ATI’s transducers have a three sensing beam configuration, where the three beams are

equally spaced around a central hub and attached to the outside wall of the transducer. This

design transfers applied loads to multiple sensing beams and allows the transducer to

increase its sensing range in a given axis if a counterpart axis has reduced loading (see

Section 7.2’s compound loading information).

The resolution of each transducer axis depends on how the applied load is spread among the

sensing beams. The best resolution occurs in the scenario when the quantization of the

gauges is evenly distributed as load is applied. In the worst case scenario, the discrete valve

of all involved gauges increases at the same time. The typical scenario will be somewhere in

between these two.

F/T resolutions are specified as typical resolution, defined as the average of the worst and

best case scenarios. Because both multi-gauge effects can be modeled as a normal

distribution, this value represents the most commonly perceived, average resolution. The

DAQ F/T resolutions are based on real-number calculations and do not result in clean

fractions. To express the values as clean fractions, we simply use the values that a 16-bit

DAQ card could achieve. Although this misrepresents the actual performance of the

transducers, it results in a close (and always conservative) estimate.

6.5 Environmental

The standard F/T system is designed to be used in standard laboratory or light-manufacturing

conditions. Transducers with an IP65 designation are able to withstand dusty environments,

as well as wash down.

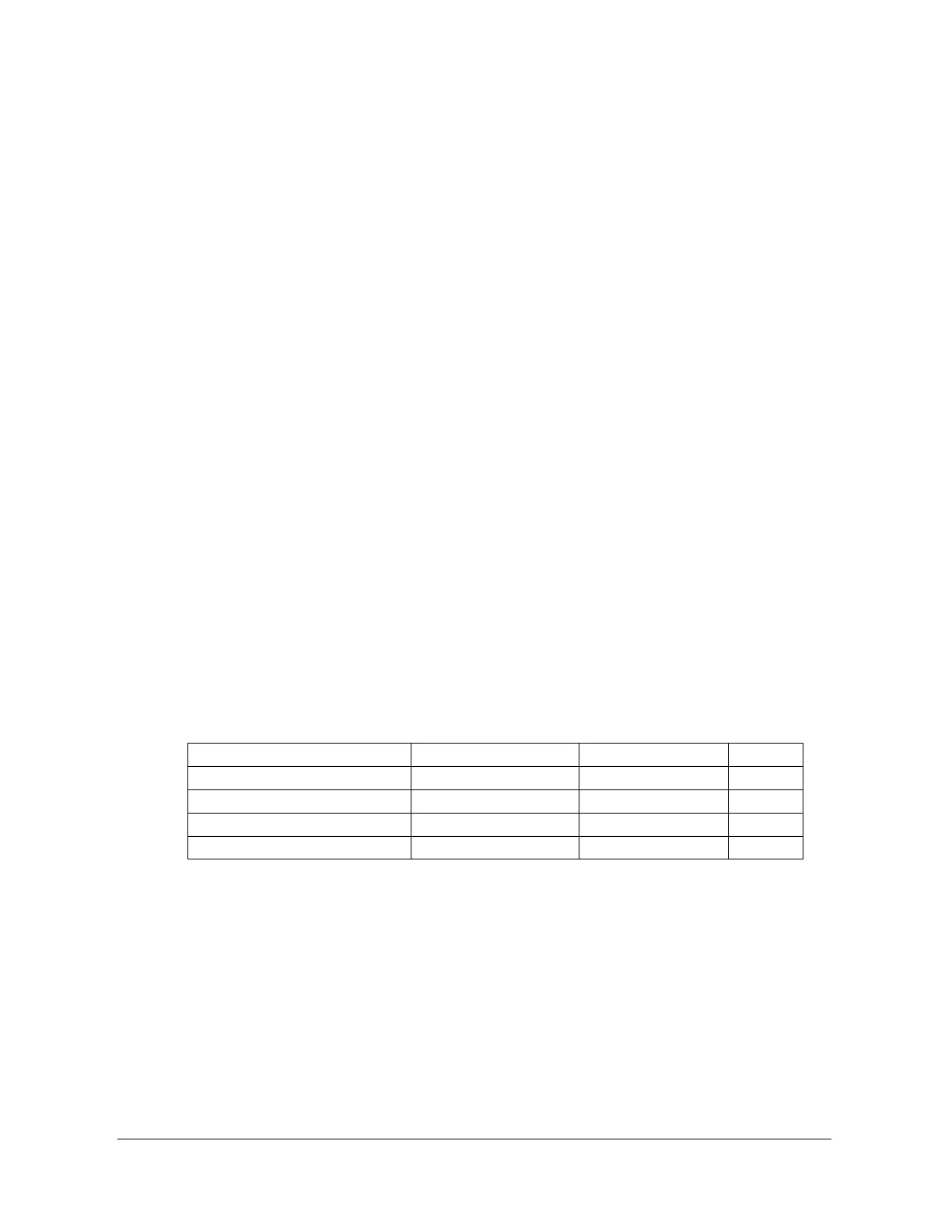

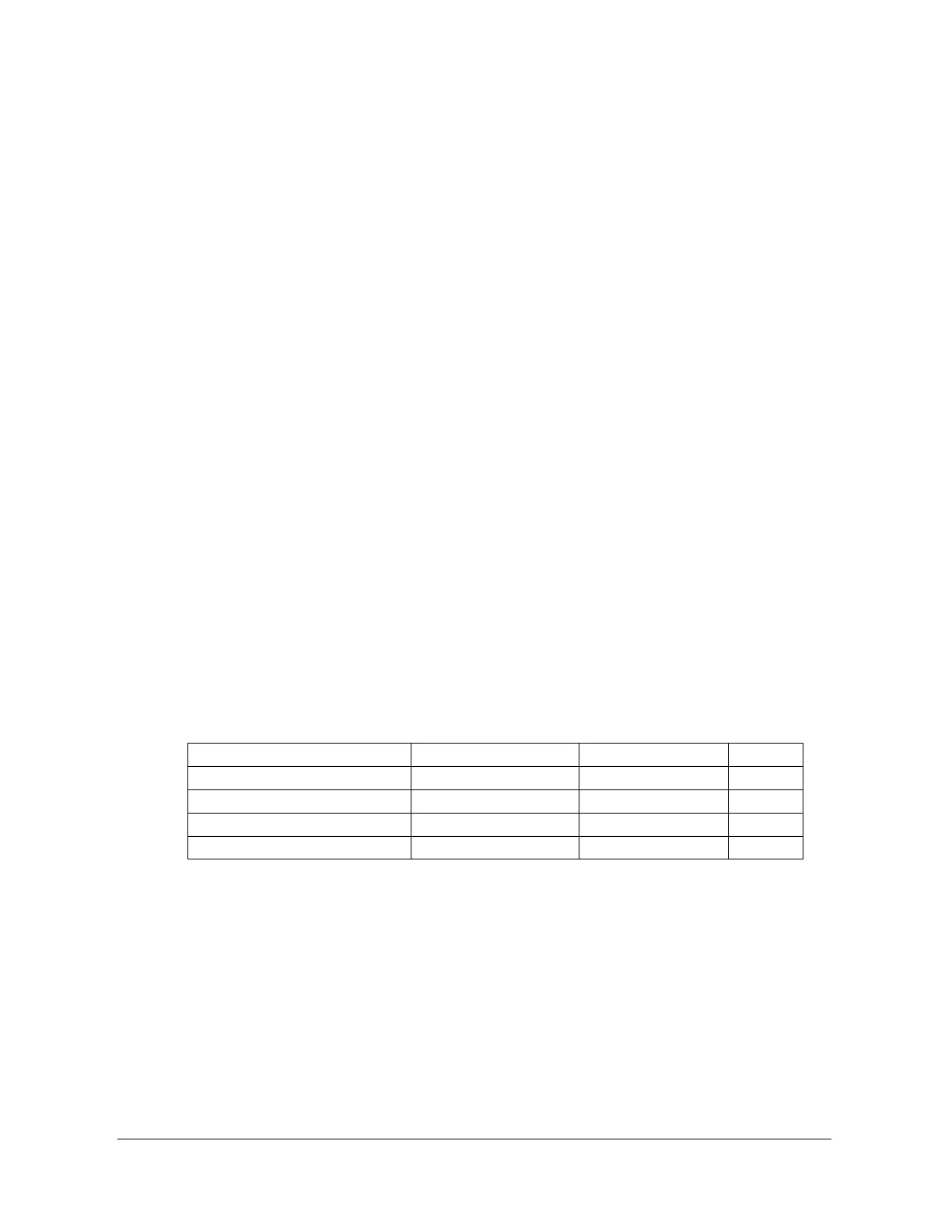

Storage Operation Units

9105-TIF Transducer -5 to 75 0 to 60

o

C

9105-TW Transducer -5 to 120 -5 to 120

o

C

PS box -30 to 75 0 to 60

o

C

IFPS box -30 to 75 0 to 60

o

C

Note: These temperature ranges specify the storage and operation ranges in which the

transducer can survive without damage. They do not take accuracy into account.

Table 6.1—Transducer Temperature Ranges

6.6 Accuracy Over Temperature

Typical errors introduced over temperature for F/T transducers with hardware temperature

compensation are listed below. These changes in sensitivity are independent of the

transducer’s rated accuracy at room temperature; the two accuracy ratings must be added to

find an overall estimated accuracy at a certain temperature. This overall accuracy assumes

that the unloaded and loaded measurements were taken at the same temperature.

Loading...

Loading...