3. Transport, storage and packaging

3.1. Transport

For transport to place of installation, use sturdy packaging.

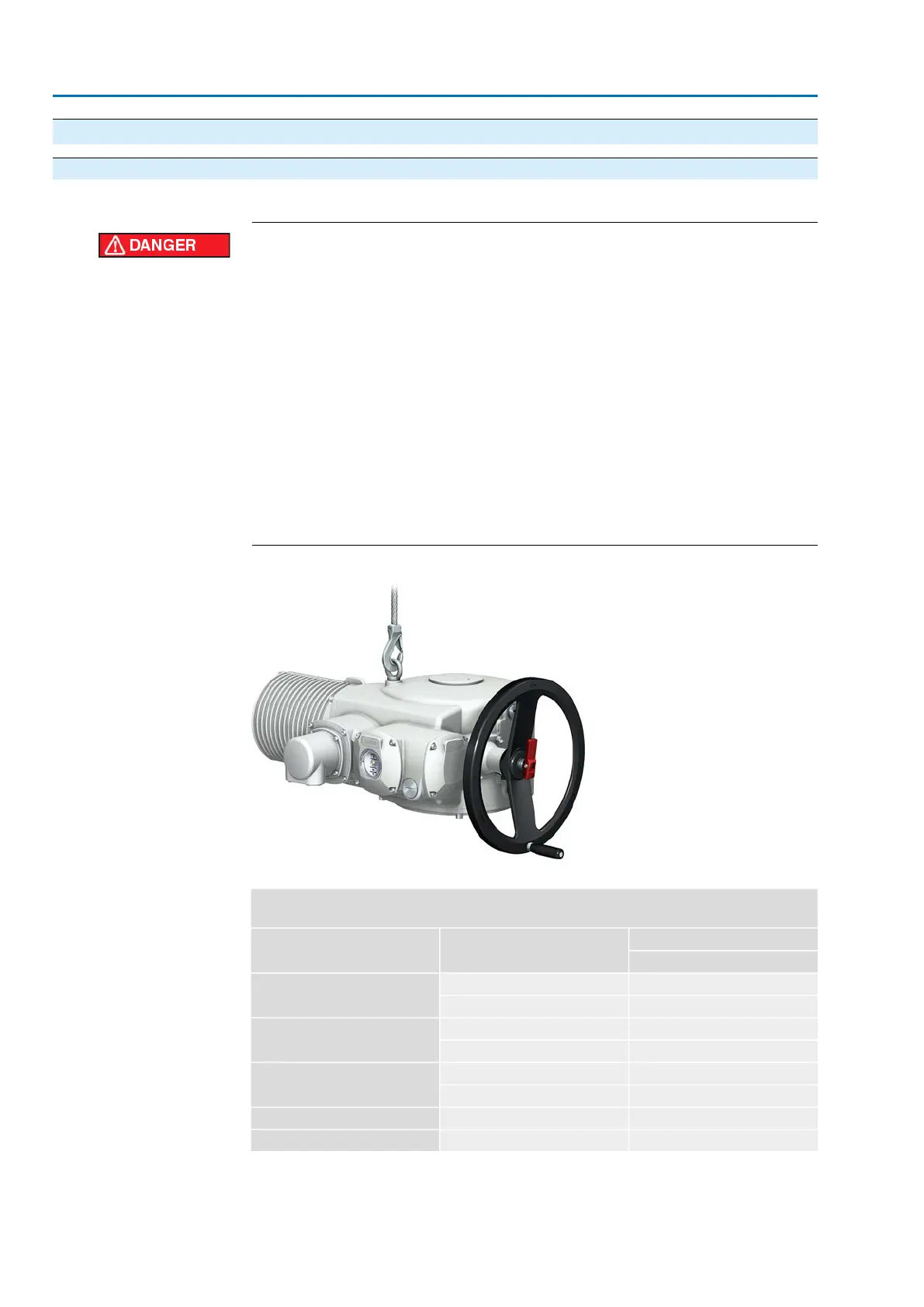

Hovering load!

Risk of death or serious injury.

→

Do NOT stand below hovering load.

→

Attach ropes or hooks for the purpose of lifting by hoist only to housing and NOT

to handwheel.

→

Actuators mounted on valves: Attach ropes or hooks for the purpose of lifting

by hoist to valve and NOT to actuator.

→

Actuators mounted to gearboxes: Attach ropes or hooks for the purpose of lifting

by hoist only to the gearbox using eyebolts and NOT to the actuator.

→

Actuators mounted to controls: Attach ropes or hooks for the purpose of lifting

by hoist only to the actuator and NOT to the controls.

→

Respect total weight of combination (actuator, actuator controls, gearbox, valve)

→

Secure load against falling down, sliding or tilting.

→

Perform lift trial at low height to eliminate any potential danger e.g. by tilting.

Figure 7: Example: Lifting the actuator

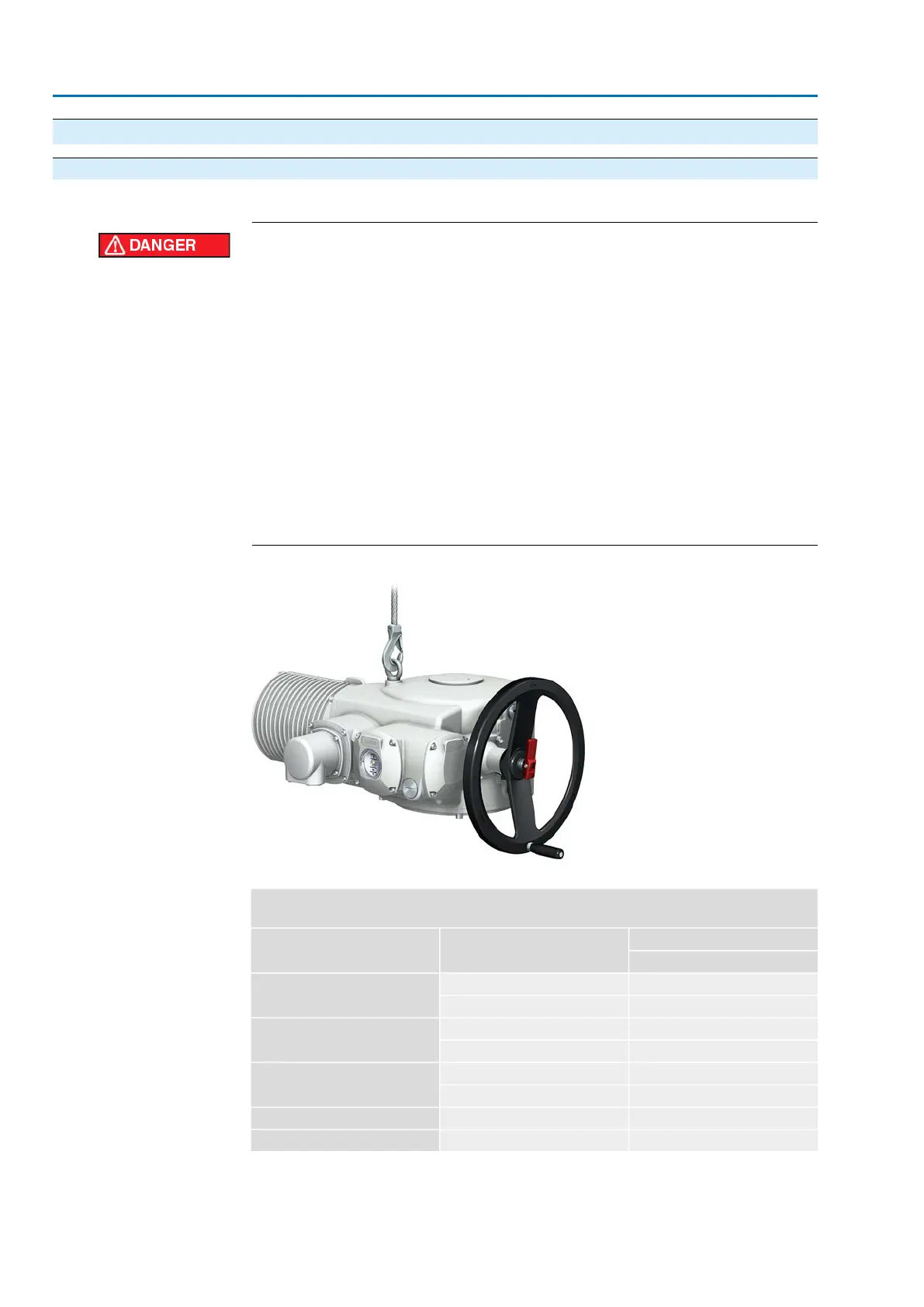

Table 3:

Weights for multi-turn actuators SA 25.1 – SA 48.1 / SAR 25.1 – SAR 30.1

with 3-phase AC motors

Weight

2)

Motor type

1)

Type designation

Actuator

approx. [kg]

150AD... 90-...SA 25.1/

SAR 25.1

160AD... 132-...

190AD... 112-...SA 30.1/

SAR 30.1

260AD... 160-...

410AD... 132-...SA 35.1

425AD... 160-...

510AD... 160-...SA 40.1

750AD... 180-...SA 48.1

Refer to motor name plate1)

Indicated weight includes AUMA NORM multi-turn actuator with 3-phase AC motor, electrical con-

nection in standard version, output drive type B1 and handwheel. For other output drive types, heed

additional weights.

2)

12

SA 25.1 – SA 48.1 / SAR 25.1 – SAR 30.1

Transport, storage and packaging AM 02.1

Loading...

Loading...