3. Switch on actuator in direction CLOSE and observe direction of rotation at hollow

shaft [3] or stem [5]:

➥

The direction of rotation is correct if the actuator moves in direction CLOSE

and the hollow shaft in clockwise direction, or the stem moves downward.

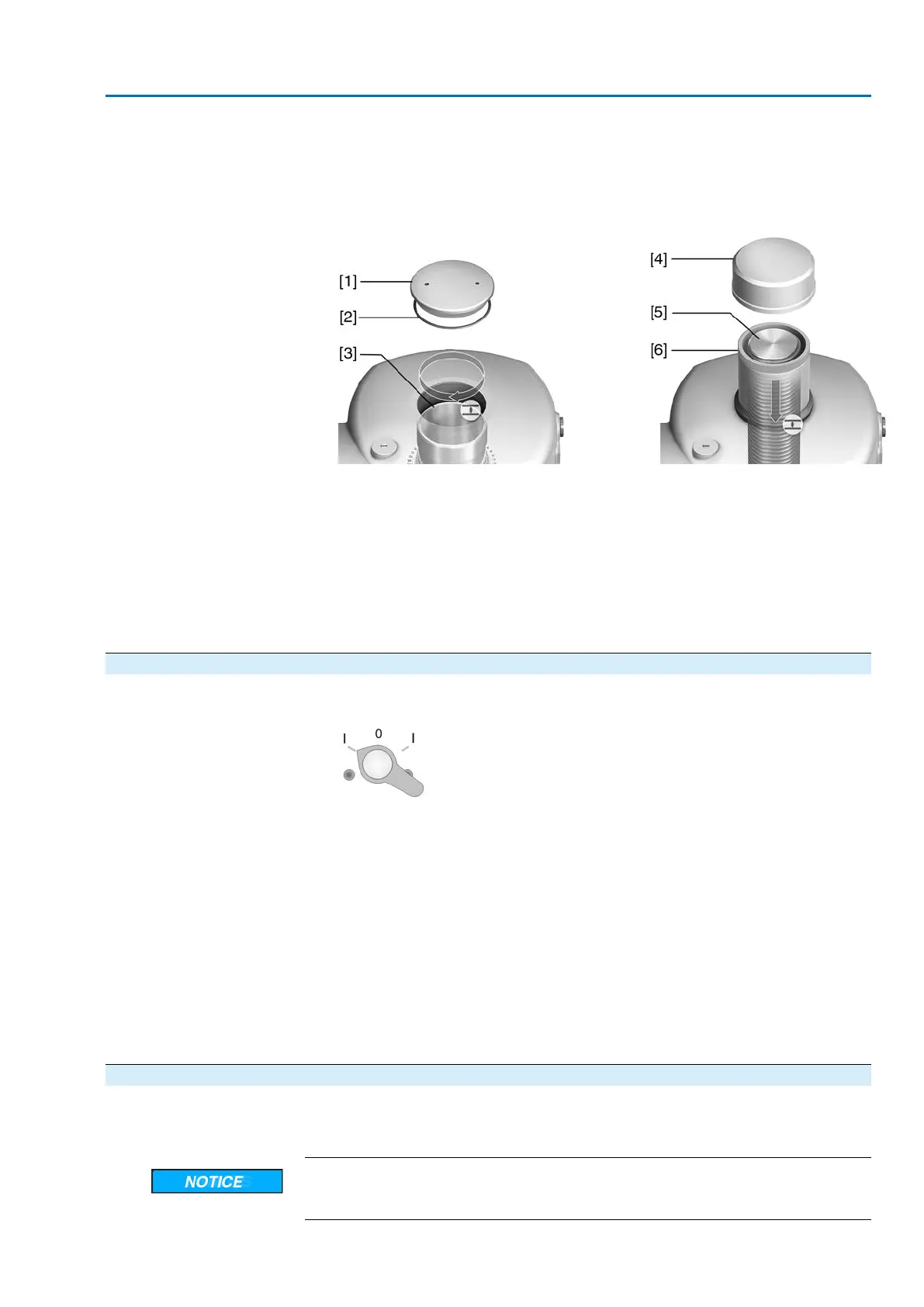

Figure 49: Hollow shaft/stem movement (for “clockwise closing”)

[1] Threaded plug

[2] Seal

[3] Hollow shaft

[4] Protective cap for stem protection tube

[5] Stem

[6] Stem protection tube

4. Correctly fit/screw on threaded plug [1] and seal [2] or protective cap for stem

protection tube [4], fasten thread.

9.5.3. Limit switching: check

1. Set selector switch to position Local control (LOCAL).

2. Operate actuator using push buttons OPEN, STOP, CLOSE.

➥

The limit switching is set correctly if (default indication):

- the yellow indication light is illuminated in end position CLOSED

- the green indication light is illuminated in end position OPEN

- the indication lights go out after travelling into the opposite direction.

➥

The limit switching is set incorrectly if:

- the actuator comes to a standstill before reaching the end position

- the red indication light is illuminated (torque fault).

3. If the end position setting is incorrect: Reset limit switching.

4. If the end position setting is correct and no options (e.g. potentiometer, position

transmitter) are available: Close switch compartment.

9.6. Switch compartment: close

✔

If options (e.g. potentiometer, position transmitter) are available: Only close switch

compartment once all optional equipment has been successfully set.

Danger of corrosion due to damage to paint finish!

→

Touch up damage to paint finish after work on the device.

47

SA 25.1 – SA 48.1 / SAR 25.1 – SAR 30.1

AM 02.1 Commissioning (basic settings)

Loading...

Loading...