The limit seating is used to signal that the limit switching will trip shortly before

reaching the set tripping torque. If this is not the case, either the indication light on

the local controls or the alarm contact K9 (collective fault signal) will signal a fault.

→

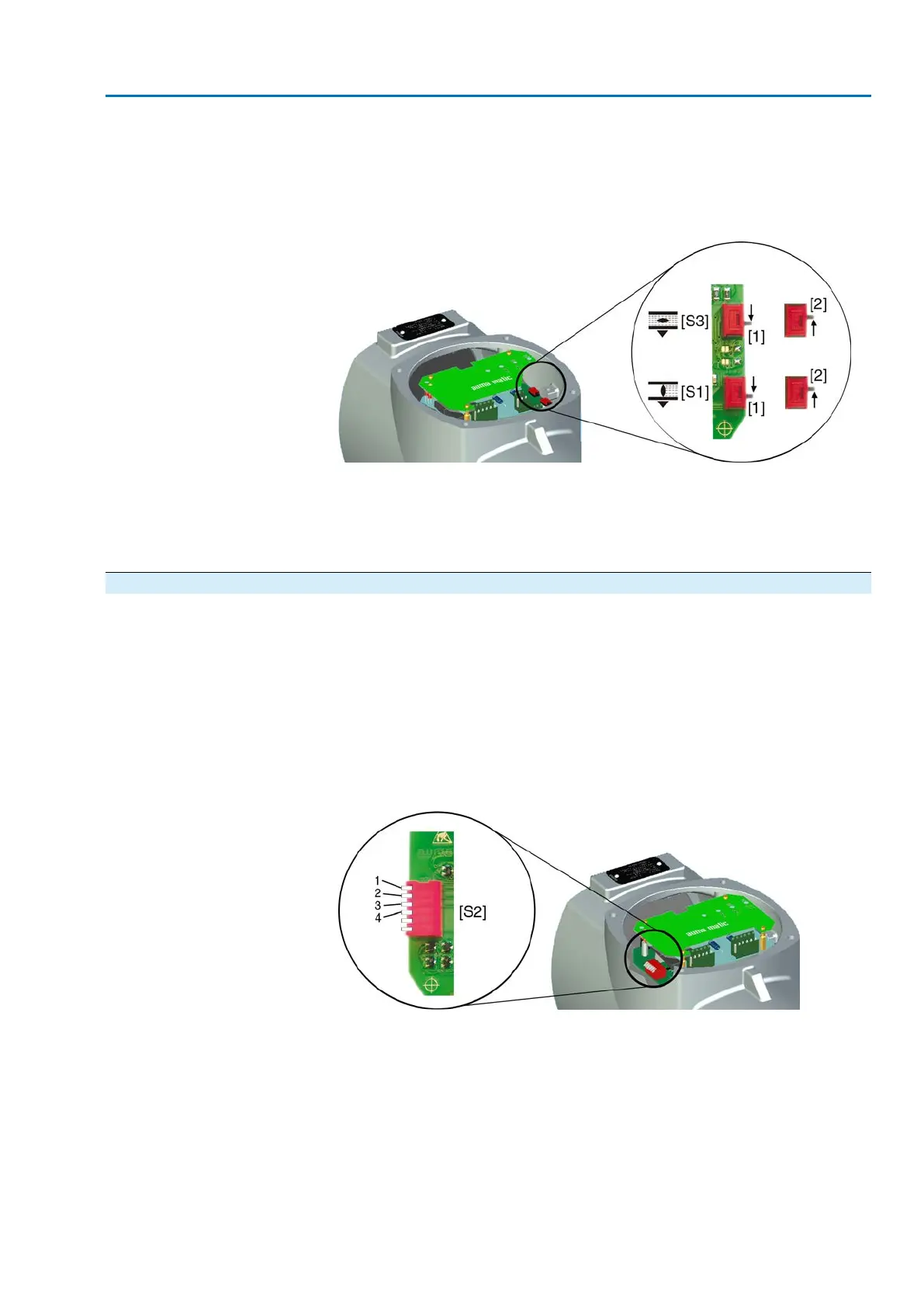

Set type of seating for end positions via DIP switches [S1] and [S3].

Figure 55: DIP switches on logic board

[S1] DIP switch for end position CLOSED

[S3] DIP switch for end position OPEN

[1] Position [1] = limit seating

[2] Position [2] = torque seating

11.3. Push-to-run operation or self-retaining: set

Push-to-run operation or self-retaining is set via a DIP switch on the logic board.

Push-to-run operation

Actuator only runs in direction OPEN or CLOSE while an operation command is

being received.The actuator stops if the operation command is cancelled.

Self-retaining

After receiving an operation command, the actuator continues to run in direction

OPEN or CLOSE, even if the operation command is cancelled (self-retaining).The

actuator is either stopped by the STOP command or if an end position or intermediate

position has been reached.

→

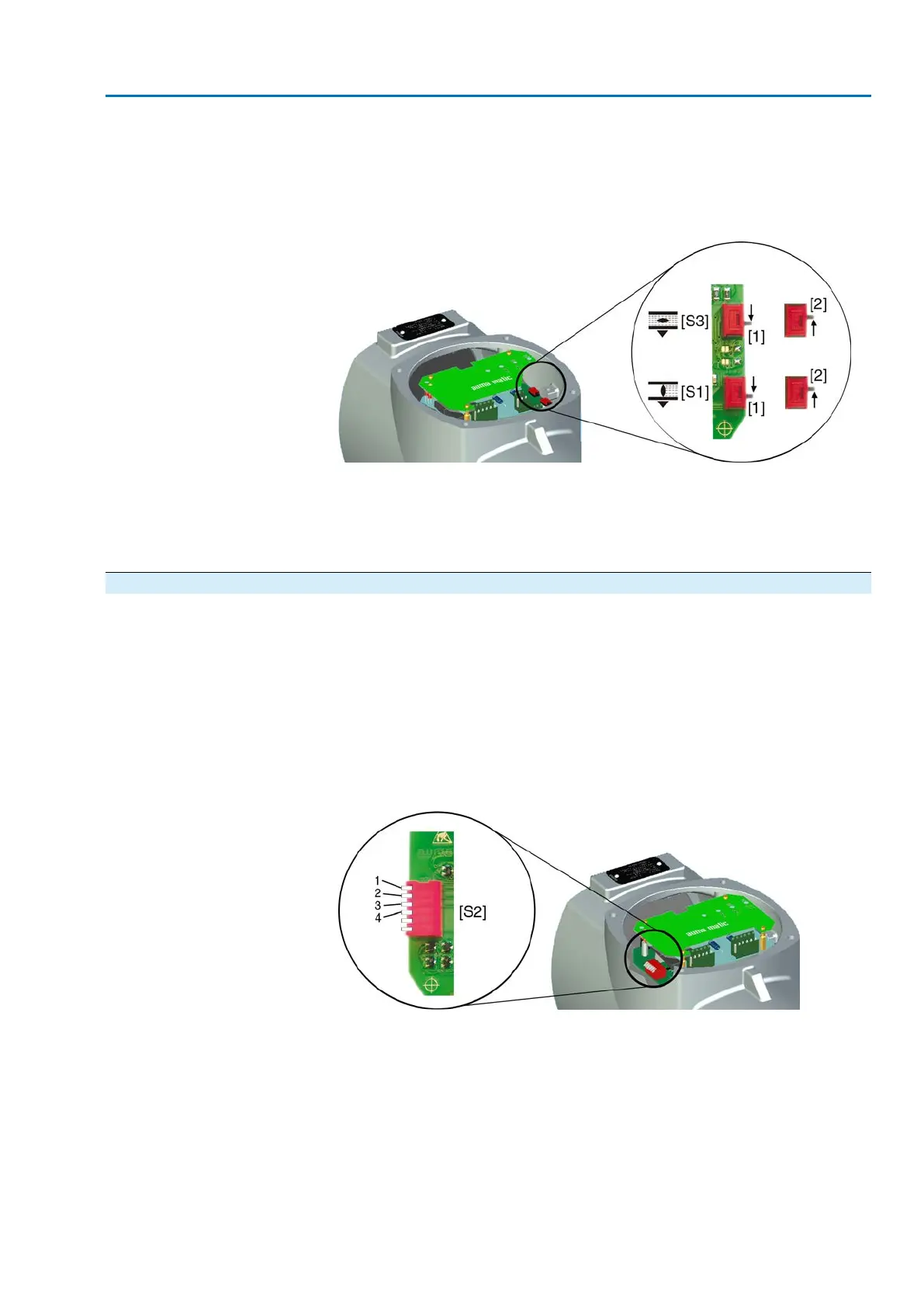

Set push-to-run operation or self-retaining via DIP switch [S2].

Figure 56: DIP switch on logic board

[S2] 6-way DIP, switches [1 – 4]:

1 for operation commands CLOSE from remote

2 for operation commands OPEN from remote

3 for operation commands CLOSE via push button at local controls

4 for operation commands OPEN via push button at local controls

➥

Switch in lower position (position ON): Self-retaining

➥

Switch in upper position (position OFF): Push-to-run operation

Information

If the controls are equipped with a positioner, switches 1 and 2 (operation commands

from remote) must be in position OFF (push-to-run operation).

57

SA 25.1 – SA 48.1 / SAR 25.1 – SAR 30.1

AM 02.1 Commissioning – controls settings

Loading...

Loading...