Terminal cross sections and terminal tightening torques

Tightening torquesTerminal cross sectionsSpeedType

4.0 – 5.0 Nm10 – 35 mm

2

4 – 11SA 40.1

6.0 – 12 Nm16 – 70 mm

2

16 – 32

4.0 – 5.0 Nm10 – 35 mm

2

4SA 48.1

6.0 – 12 Nm16 – 70 mm

2

5.6 – 16

1. Remove cable sheathing and insert the wires into the cable glands.

2. Fasten cable gland with the specified torque to ensure required enclosure pro-

tection.

3. Strip wires.

4. For flexible cables: Use end sleeves according to DIN 46228.

5. Connect cables according to order-related wiring diagram.

In case of a fault: Hazardous voltage while protective earth conductor is NOT

connected!

Risk of electric shock.

→

Connect all protective earth conductors.

→

Connect PE connection to external protective earth conductor of connecting

cables.

→

Start running the device only after having connected the protective earth con-

ductor.

6.

Firmly tighten protective earth to PE connection (symbol: ).

7. For shielded cables: Link the cable shield end via the cable gland to the housing

(earthing).

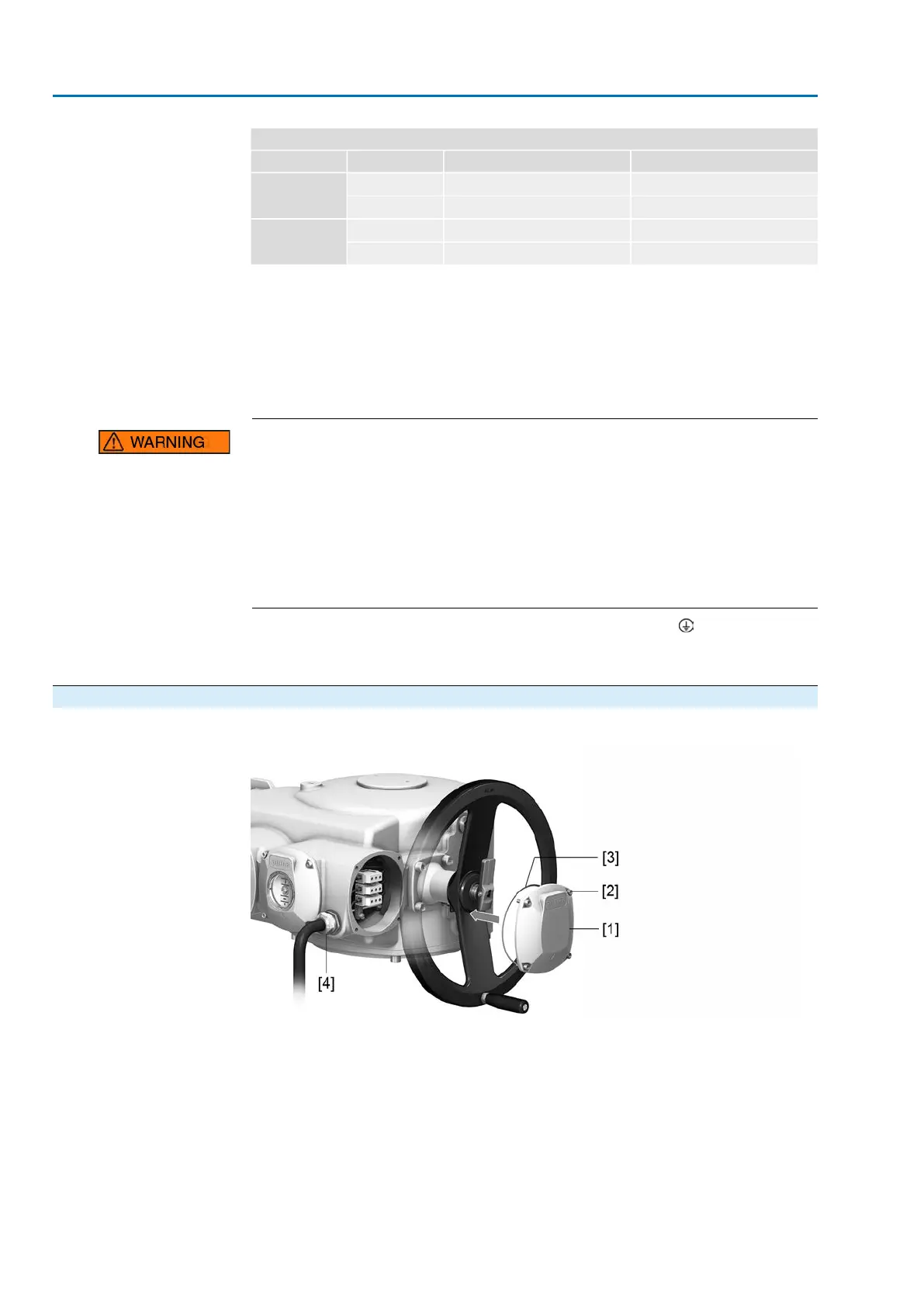

5.4.1.3. Motor connection compartment: close

Figure 30: Close motor connection compartment

[1] Cover

[2] Screws for cover

[3] O-ring

[4] Cable gland

1. Clean sealing faces of cover [1] and housing.

2. Check whether O-ring [3] is in good condition, replace if damaged.

3. Apply a thin film of non-acidic grease (e.g. petroleum jelly) to the O-ring and

insert it correctly.

4. Fit cover [1] and fasten screws [2] evenly crosswise.

30

SA 25.1 – SA 48.1 / SAR 25.1 – SAR 30.1

Electrical connection AM 02.1

Loading...

Loading...