2-27

Chapter 2 Installation of this Device

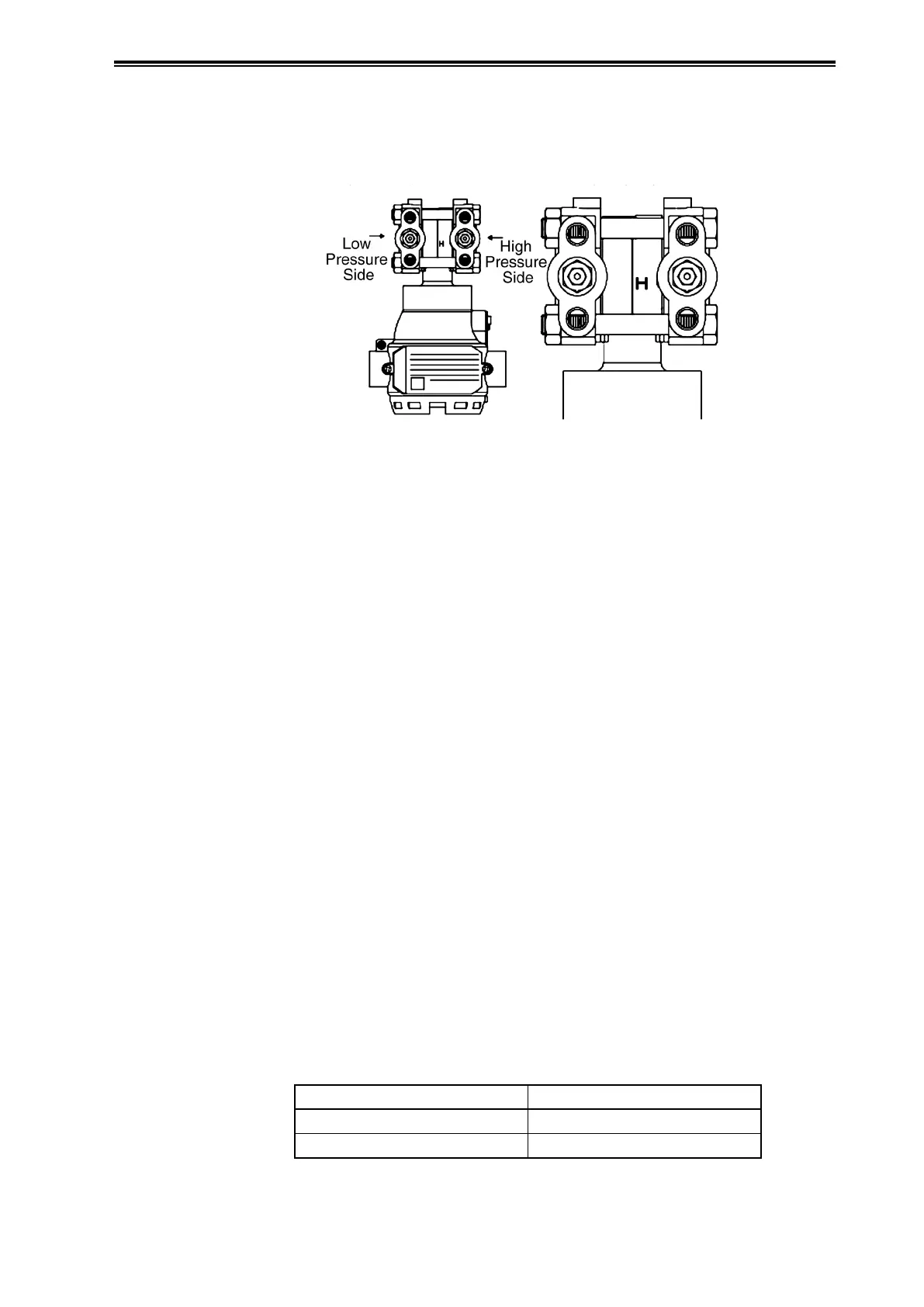

(ii) High pressure side display on this device

An “H” is displayed on the high pressure side of the main unit of this device to indicate high

pressure, so be sure to check this during piping in order to avoid mistakes. The side without a mark

is the low pressure side.

Figure 2-33. Mark on High Pressure Side of Main Unit

(iii) Selection of pipes to use

For connecting pipes from the process, select pipe schedule numbers and nominal thicknesses in

accordance with process side selection criteria (conditions such as process pressure). Diameter

1/2B, schedule number 80 steel pipes are one example of connecting pipes which are commonly

used.

(iv) Required parts example

When doing the piping work, refer to the piping example diagram, and have the following parts

ready. Select the rating, material, etc., of each part based on process side selection standards.

• Three-Way Manifold Valve

• Pipes

• Master Valves

• Unions or Flanges

• T-Joints

• Drain Valves

• Gas Vent Plugs

• Condenser (only for connecting valves for vapor flow rate measurement)

(v) Adapter flange

When doing the piping work, follow the table below for tightening torque when using an adapter

flange. Note that the bolts that fasten the adapter flange are loose when shipped.

Table 2-4. Adapter Flange Tightening Torque

Material / Bolt Size Tightening Torque (N·m)

Carbon Steel 20±2

SUS304/316 10±1

Loading...

Loading...