2-28

Chapter 2 Installation of this Device

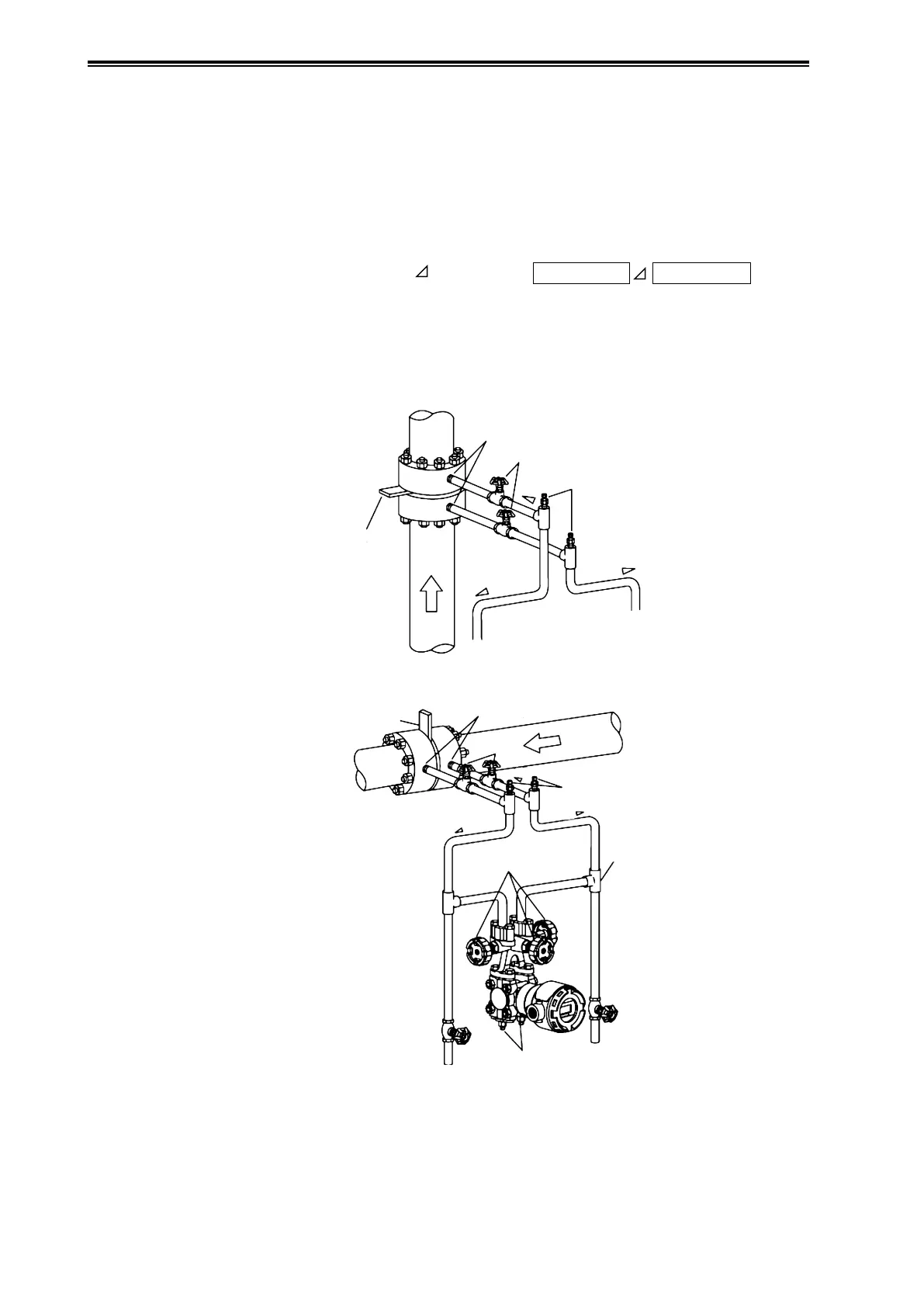

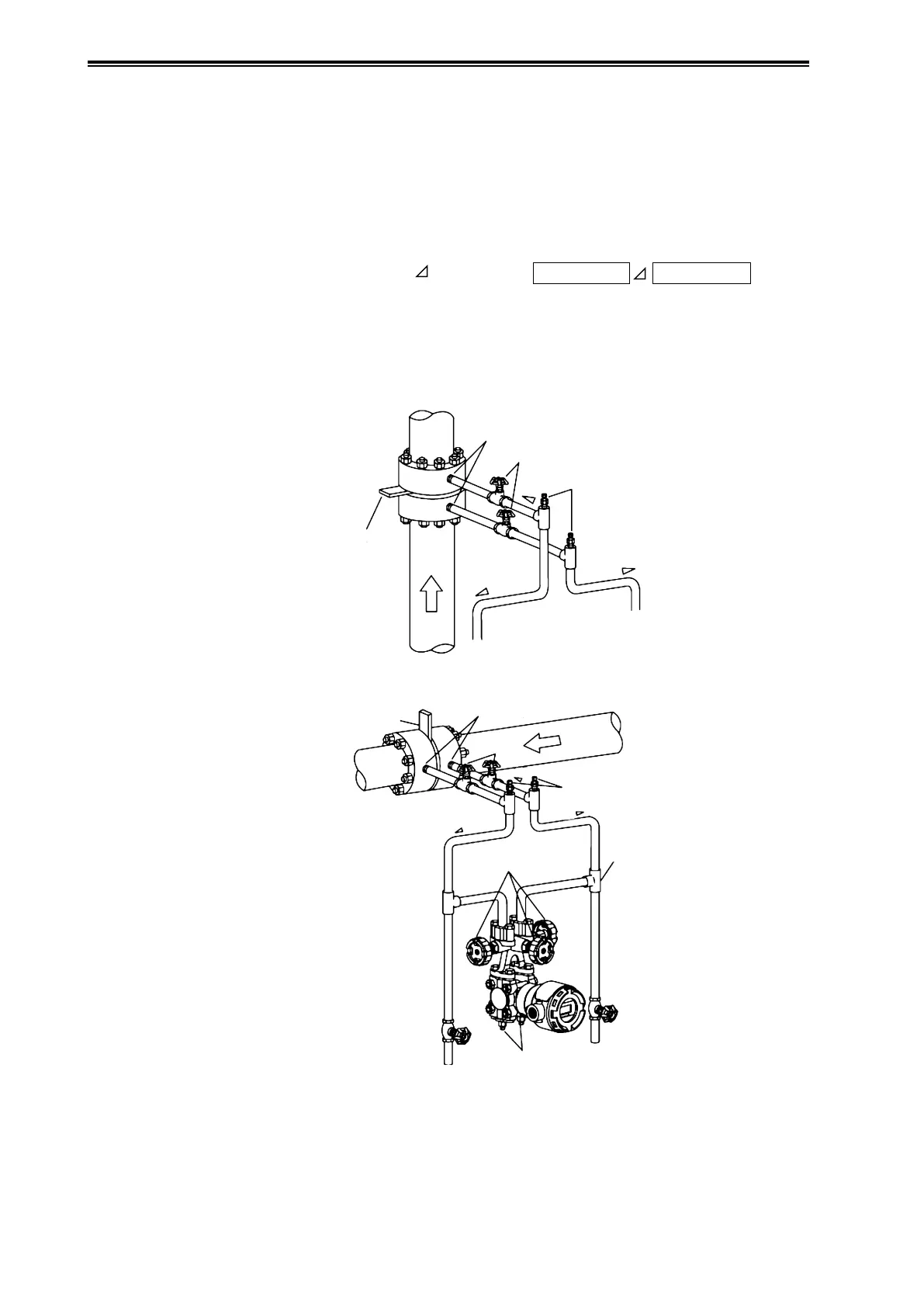

(2) Liquid or Gas Flow Rate Measurement Piping

(i) Example of recommended piping for liquid flow rate measurement

A typical piping example in which the device is lower than the differential pressure output port on

the process pipe.

Be sure to implement the following items.

• Depending on the measured fluid, create an incline in the differential pressure output pipes so

that drains, vents, etc., will clear.

Meaning of incline symbol

in the diagram:

Low position

High position

• Install gas vent plugs at locations where gas in connecting pipes exits.

• After doing the piping work, confirm that there are no pressure leaks in the connecting pipes,

the three-way manifold valve, the transmitter, etc.

• For the purpose of connecting pipe maintenance, use T-joints to attach drain valves.

Master Valves

Master

Valve

Orice

Orice

Three-Way

Manifold Valve

Drain

Plugs

Drain

Valve

Drain

Valve

Dierential Pressure Outlets

Dierential Pressure

Outlets

High

Pressure

Side

High

Pressure

Side

Low

Pressure

Side

Low

Pressure

Side

Incline

Incline

Incline

Incline

Incline

Incline

Gas Vent Plugs

Gas Vent Plugs

T-Joint

Process Pipe (Vertical)

Figure 2-34. Example of Piping for Liquid Flow Rate Measurement

Loading...

Loading...