2-30

Chapter 2 Installation of this Device

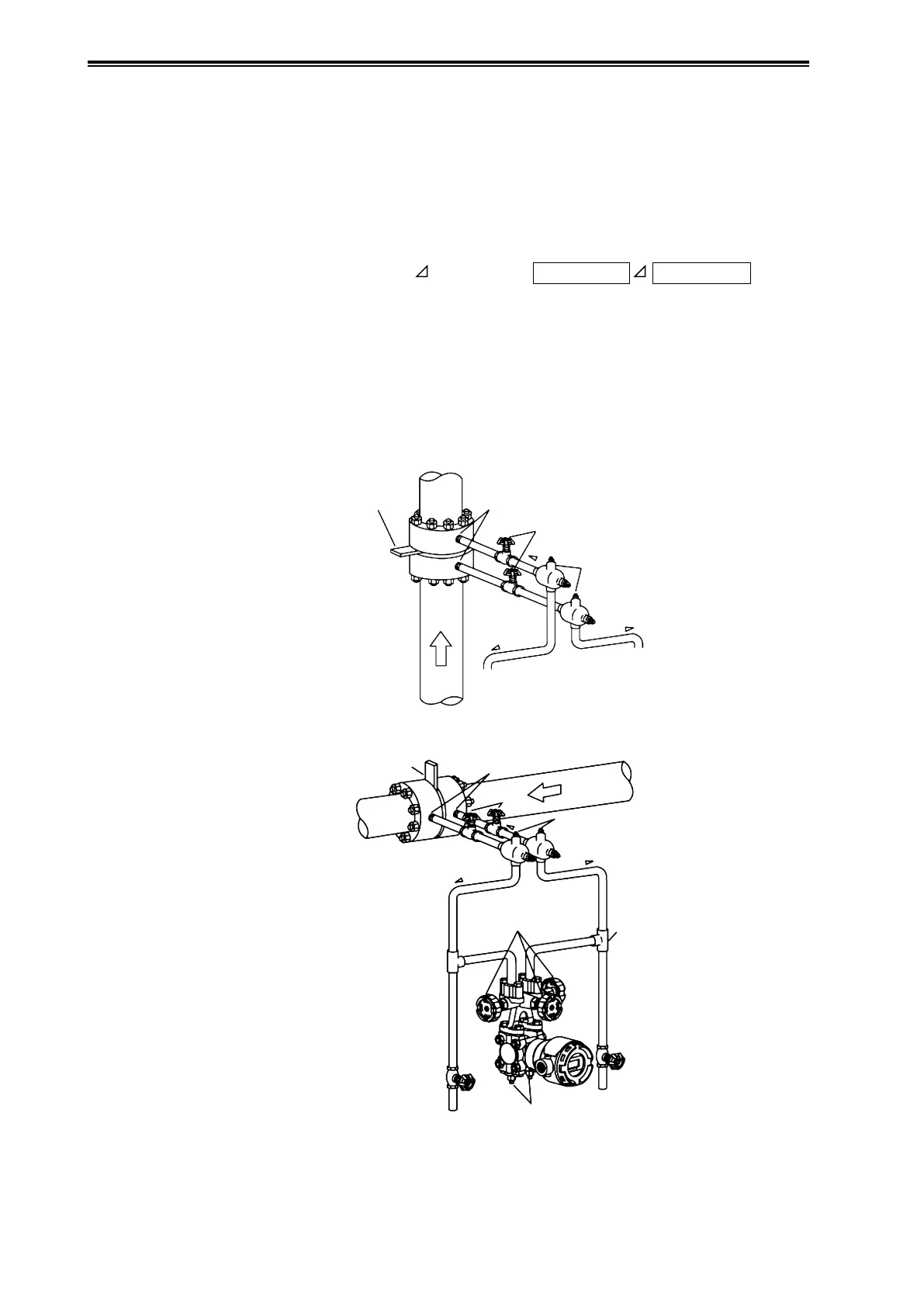

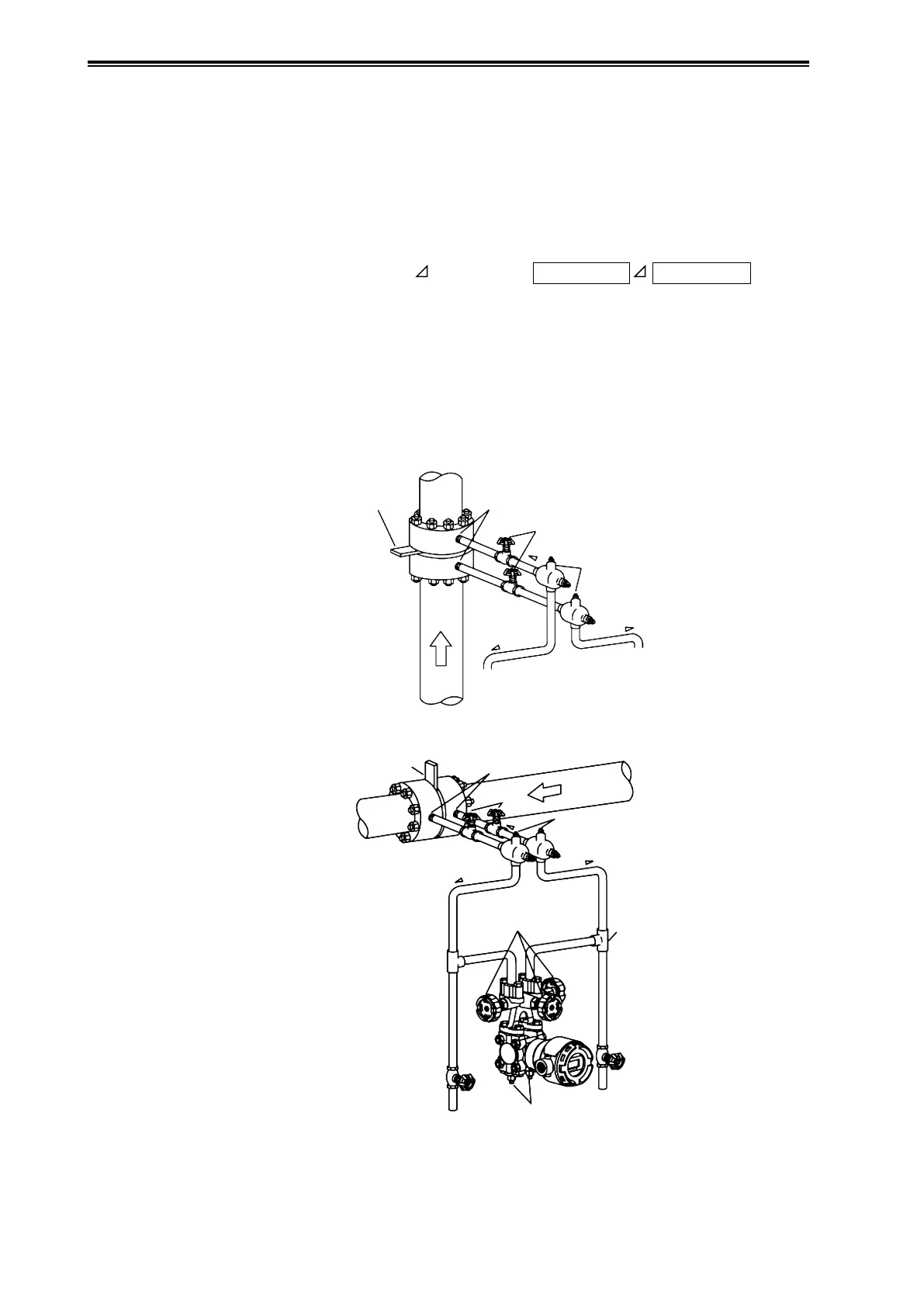

(3) Vapor Flow Rate Measurement Piping

(i) Recommended piping example

A typical piping example is illustrated below. With this vapor flow rate measurement piping,

the device is installed lower than the differential pressure output port.

Be sure to implement the following items.

• Depending on the measured fluid, create an incline of at least 1/10 in the differential pressure

output pipes so that drains will clear.

Meaning of incline symbol

in the diagram:

Low position

High position

• After doing the piping work, confirm that there are no pressure leaks in the connecting pipes,

the three-way manifold valve, the transmitter, etc.

• For the purpose of connecting pipe maintenance, use T-joints to attach drain valves.

• If the process has a vertical pipe, installing the condensers different heights as shown in the

diagram prevents zero drift in the differential pressure gauge, which otherwise would occur

readily. Incidentally, in this case it is not possible to perform zero adjustment using the three-

way manifold valve.

Master Valves

Master

Valves

Drain Plugs

Drain

Valve

Drain

Valve

Three-Way Manifold Valve

Orice

Orice

Dierential Pressure Outlets

Dierential

Pressure Outlets

T-Joint

High

Pressure Side

High

Pressure

Side

Low

Pressure Side

Condensers

Condensers

Low

Pressure

Side

Incline

Incline

Incline

Incline

Incline

Process Pipe (Vertical)

Figure 2-36. Vapor Flow Rate Measurement Piping Example

Loading...

Loading...