66 of 109

Needle Types and Replacements

Embroidery quality can be greatly effected by your choice of needles. You

will need to nd what works best with your applications. The following

information should help.

Replacing a Needle

Sew conditions and material properties will affect the life of a

needle, but eventually, needles will need to be changed.

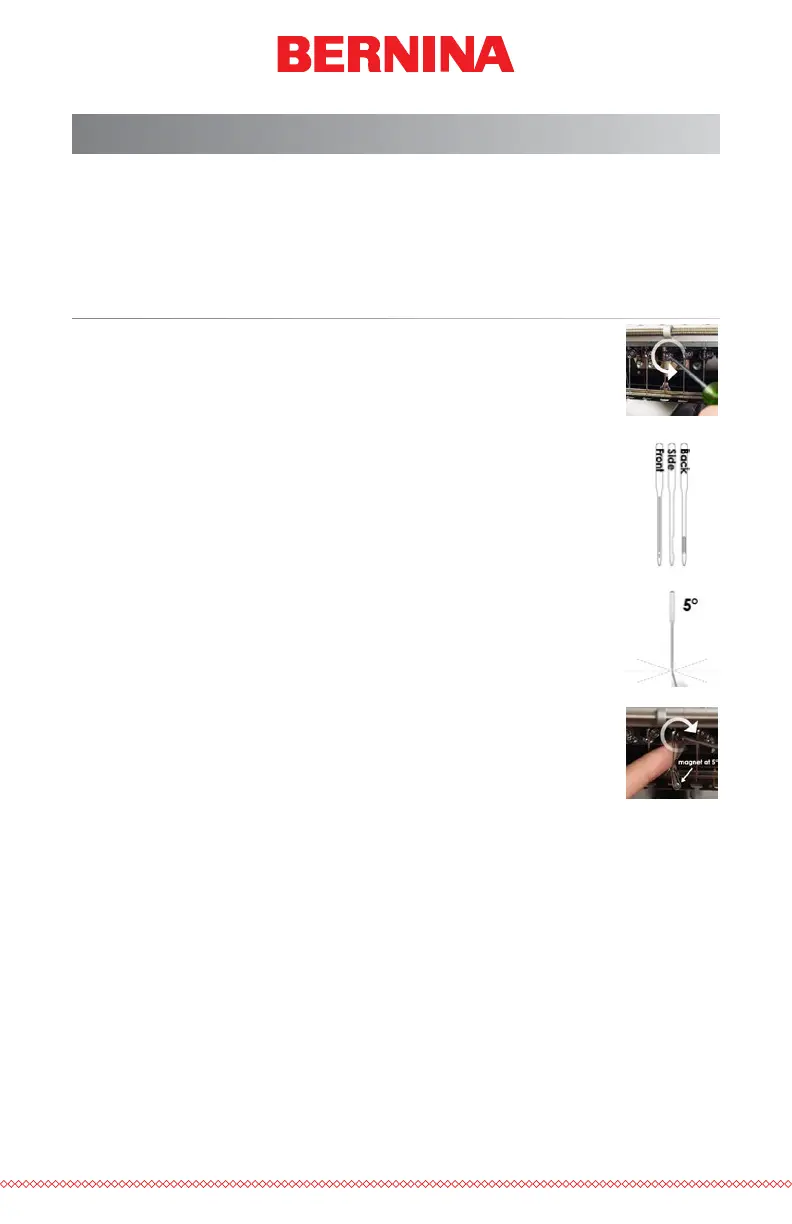

1. Make sure the safety grabber blade is in the back

position before changing a needle. If it is not, press the

Adjustment and Center keys on the machine keypad to

move the grabber back.

2. Above each needle is a needle clamp set screw that

holds it in place. Using a small at-blade screwdriver,

turn the needle clamp set screw counterclockwise

about a half of a turn, until the needle can slide down

and out of the needle bar. Do not loosen too much or

remove the set screw. Loosen the screw just enough

for the needle to be removed.

3. Remove the needle by pulling down on the needle.

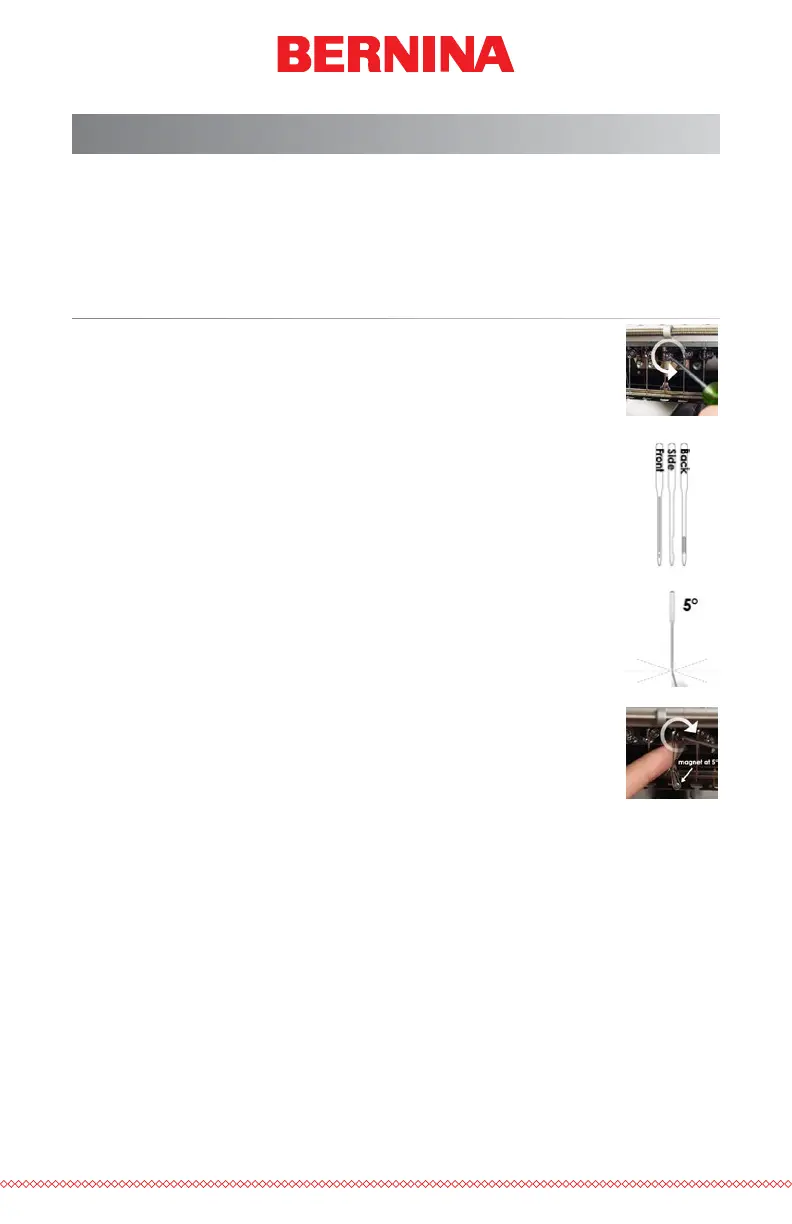

4. Embroidery needles have a front and a back side. The

needle must be installed correctly or the sew quality

may suffer. If you install the needle incorrectly, you my

also get thread breaks. The front of the needle has a

long groove (thread guide), while the back has an indented notch

(scarf) just above the eye of the needle.

5. With the thread guide facing forward and the scarf facing back,

slide the needle up and into the needle clamp as far as it will go.

The eye of the needle should then be turned 5° to the right. The

acceptable range is 0° - 20° to the right.

6. A needle orientation magnet may be used to help determine the

angle of the needle eye. This cylindrical magnet can be temporarily

attached to the front of the needle just above the eye. The end

of the magnet will rest on each side of the thread guide and stick

straight out from the needle. This will better indicate the angle of

the eye. For reference, one minute is 6° on a clock face.

Loading...

Loading...