“ICON 2000v4"

instruction and operating manual

© Copyright by BIFFI Italia. All right reserved. Section 618/42 Page 15

Contents may change without notice

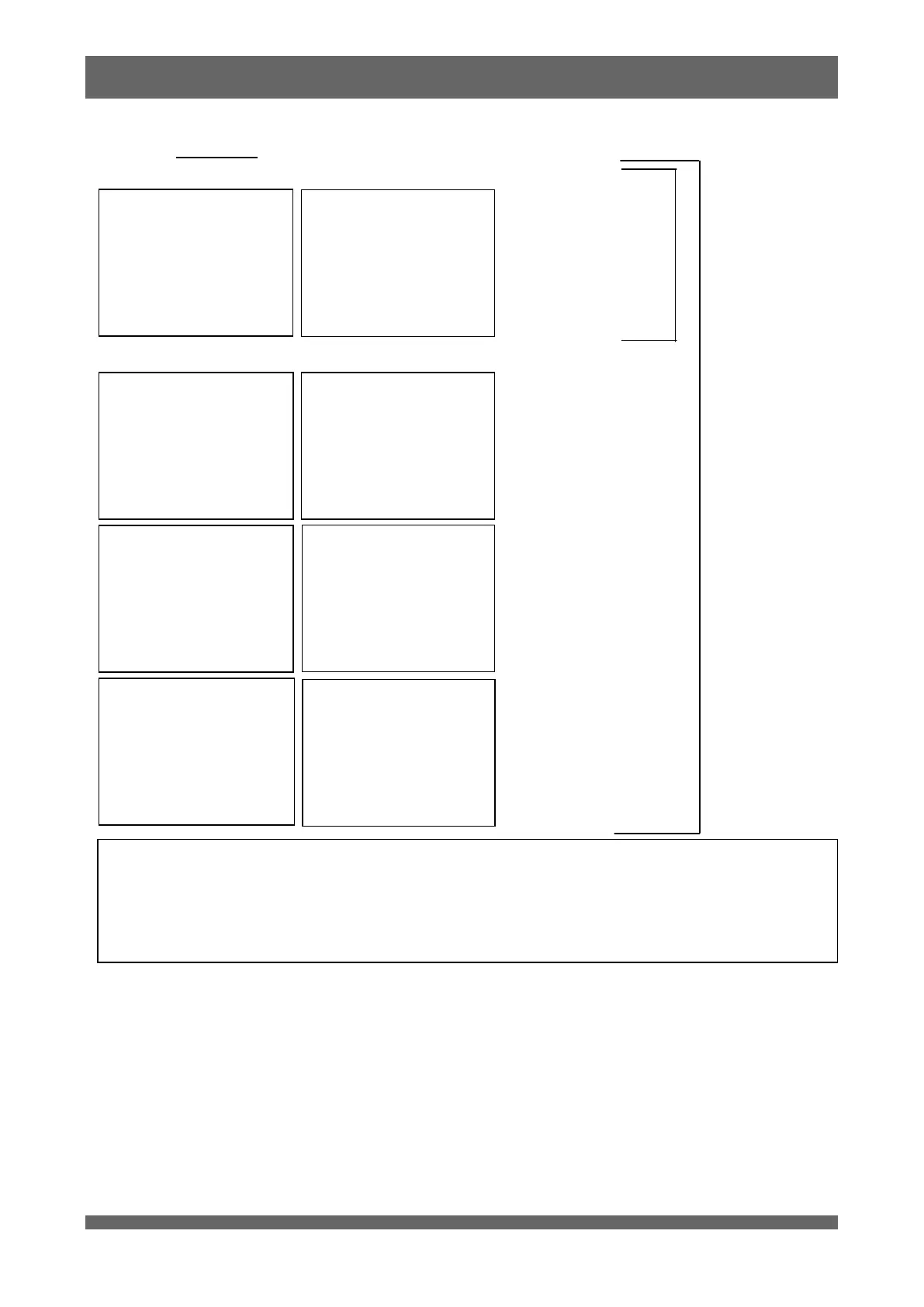

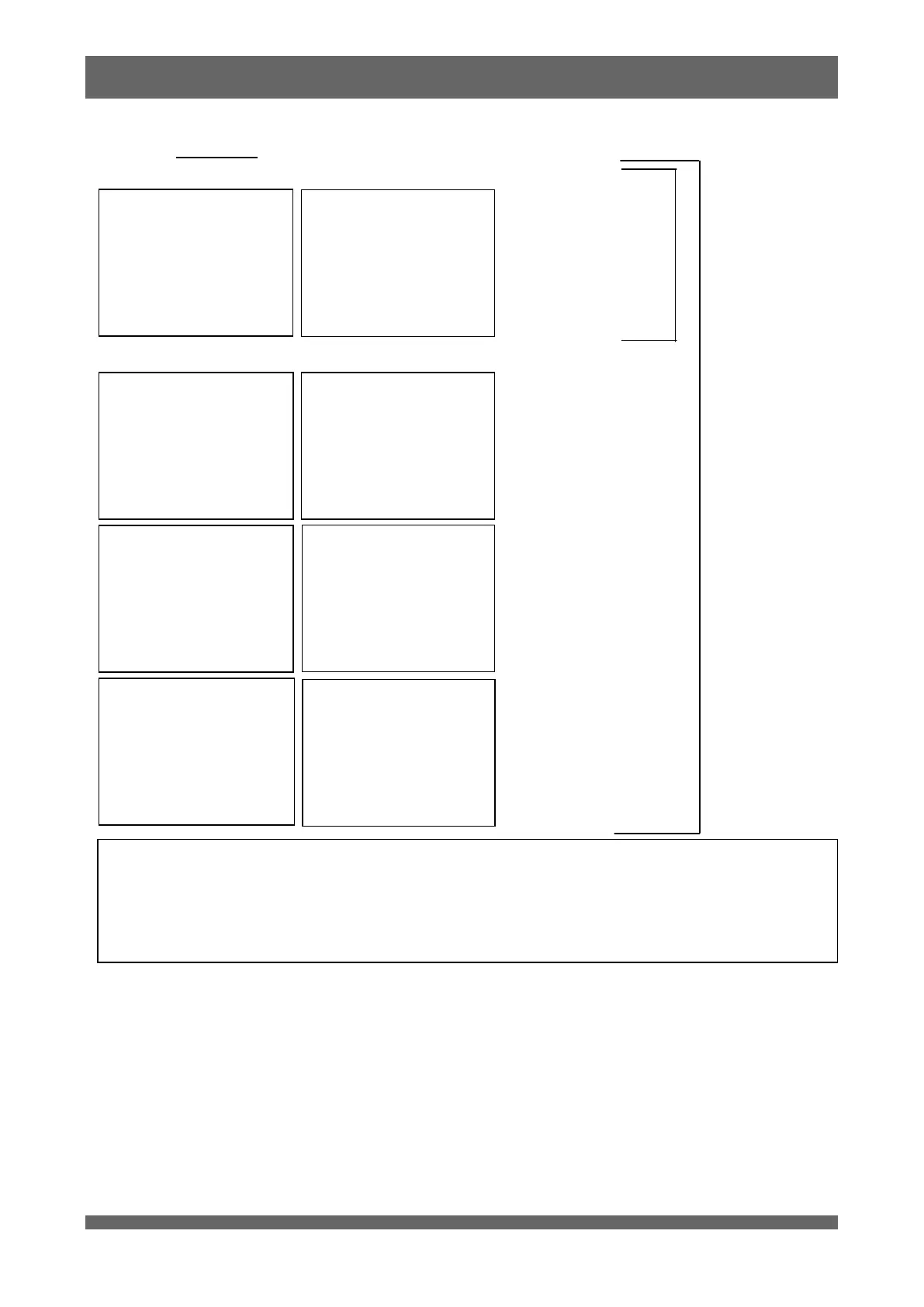

10.1.2 Input data

DIN setting

Via local operator interface of actuator, the DIN bits can be individually set to 1 if one of the following condition

occurs:

low alkaline battery (if present)

mid travel alarm in Op or CL

BYTE = 0

Bit 0=1 : Close limit

Bit 1=1 : Open limit

Bit 2=1 : Closing

Bit 3=1 : Opening

Bit 4=1 : ESD active

Bit 5=1 : Loc. Sel. on Remote

Bit 6=1 : Loc. Sel. on Local

Bit 7=1 : Loc. Sel. on Off

BYTE = 4

Bit 0=1 : Monitor relay

Bit 1=1 : Motion inhibited

Bit 2=1 : DIN 1

Bit 3=1 : DIN 2

Bit 4=1 : DIN 3

Bit 5=1 : DIN 4

Bit 6=1 : DIN 5

Bit 7=1 : DIN 6

BYTE = 2

ACTUATOR POSITION §

BYTE = 1

Bit 0=1 : Interlock open active

Bit 1=1 : Interlock close active

Bit 2=1 : Fail safe action

Bit 3=1 : Int. data updated *

Bit 4=1 : Warning

Bit 5=1 : Channel 1 active

Bit 6=1 : Valid data **

Bit 7=1 : Alarm

BYTE = 5

Bit 0=1 : Aux_in_open

Bit 1=1 : Aux_in_close

Bit 2=1 : Aux_in_stop

Bit 3=1 : Aux_in_bus-on

Bit 4=1 : HW remote mode

Bit 5=1 : Positioner mode

Bit 6 : reserved

Bit 7 : reserved

BYTE = 6

OUTPUT TORQUE §§

BYTE = 3

ACTUATOR POSITION §

BYTE = 7

OUTPUT TORQUE §§

* ‘internal data updated’ is set to 1 when the Active Slave has updated its internal data area and the acyclic

communications can read updated values

** ‘valid data’ is set to 1 when the PROFIBUS interface is the Active Slave and the cyclic communications

contains valid data.

§ position: integer 16 bits (value 0 = 0% ; value 1000 = 100.0%)

§§ torque: integer 16 bits (OP: value 0 = 0%; value –100 = 100% - CL: value 0 = 0%; value +100 = 100%)

Loading...

Loading...