Brookeld Engineering Labs., Inc. Page 92 Manual No. M13-167-A0415

A.3 Setting the Gap

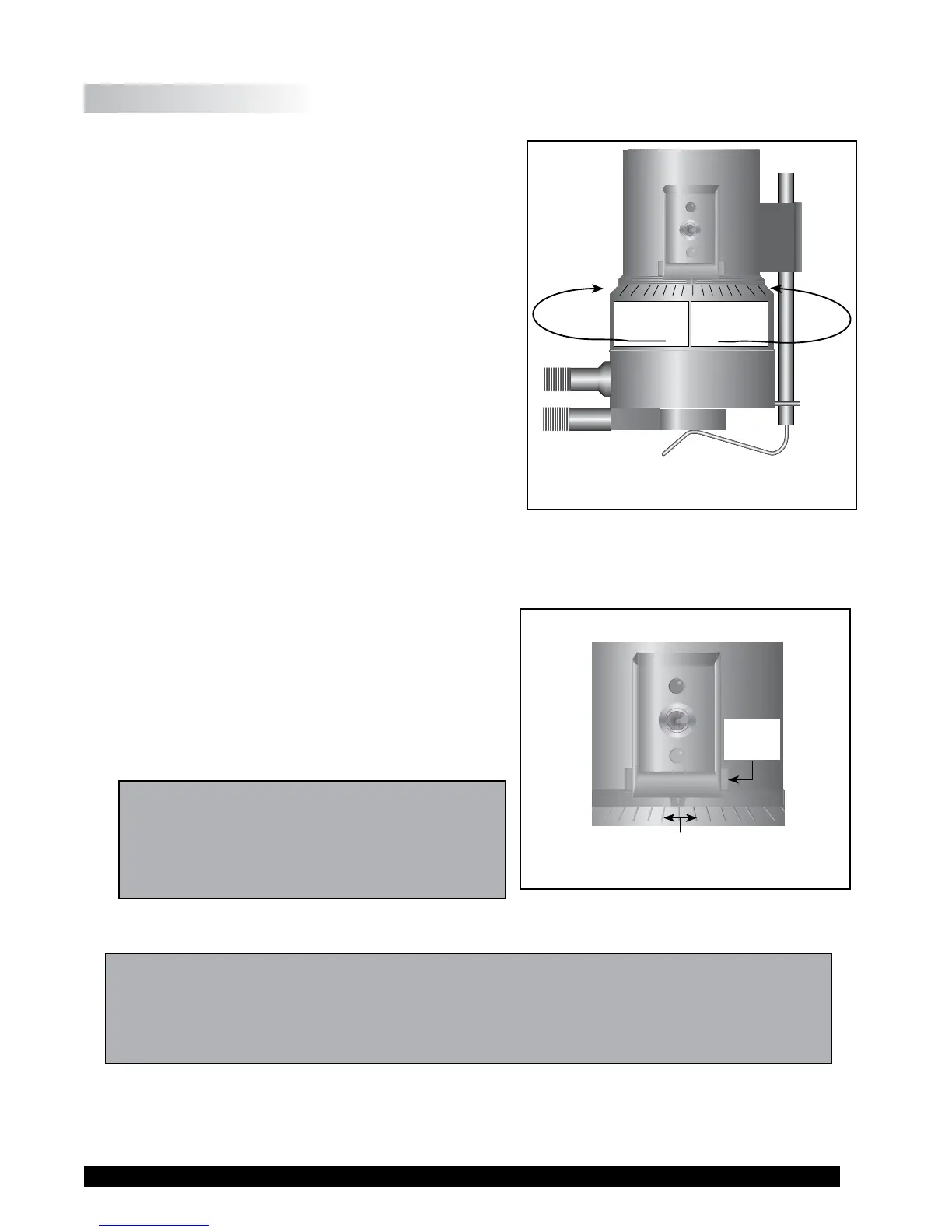

1. Movethetoggleswitchtotheright;thiswillturn

on(enable)theGapSettingFeature.ThePilot(red)

lightwillbeilluminated.

Note: The motor should be OFF.

2. Ifthecontactlight(yellow)isilluminated,turnthe

micrometeradjustmentringclockwise(asyoulook

downontheinstrument)untilthelightisnolonger

illuminated(seeFigure A-5).

3. Iftheyellowcontactlightisnotilluminated,slowly

turn the micrometer adjustment ring in small

increments (one or two scale divisions) counter-

clockwise.

Continuemovingthemicrometeradjustment ring

slowly counter-clockwise until the contact light

(yellow) rst turns on. THIS IS THE “HIT

POINT.”

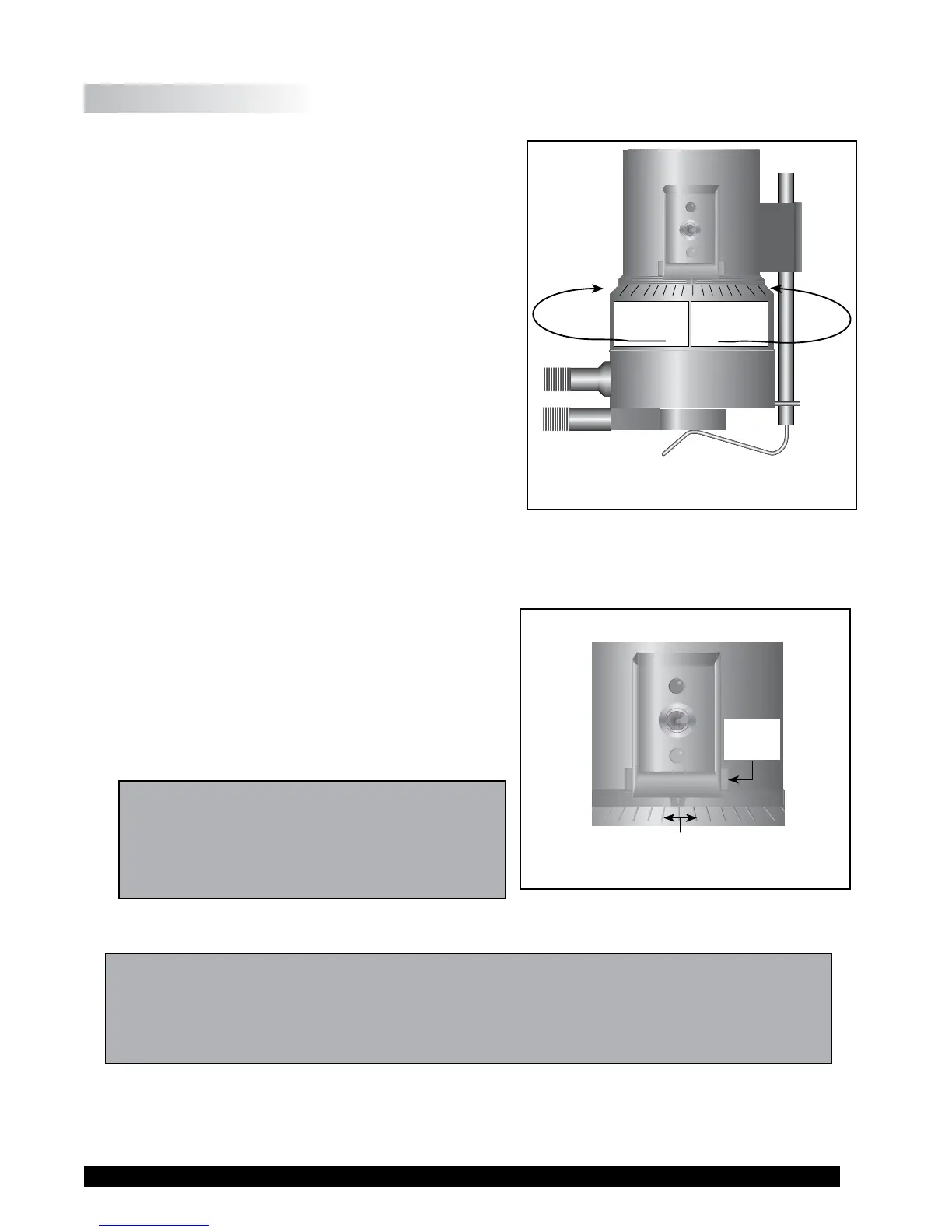

4. Adjusttheslidingreferencemarker,rightorleft,

totheclosestfullscaledivisionmark(see Figure

A-6).

5. Turn the micrometer adjustment ring one scale

divisiontothelefttomeetthelineonthesliding

reference marker. THE YELLOW CONTACT

LIGHT SHOULD GO OFF.

6. You have established the gap space needed for

measurement. Now turn the toggle switch OFF

(left);theredpilotlightshouldgooff.

Theviscosityofelectricallyconductiveuids

maybeaffectedifreadingsaretakenwiththe

ElectronicGapSettingfeature“on”.Besureto

shutthefeature“off”beforetakingreadings!

7. Carefullyremovethesamplecup.

Note:

1. The cup may be removed and replaced without resetting the gap if the micrometer

adjustmentringhasnotbeenmoved.

2. Removethespindlefromtherheometerwhencleaning.

3. Re-establishthehitpointeverytimethespindleisattached/detached.

Moves Away

from Hit Point

(clockwise)

LEFTx

Moves Towards

Hit Point

(counter-clockwise)

RIGHT

Full Scale

Division Marks

Sliding

Reference

Marker

Figure A-5

Figure A-6

Loading...

Loading...