Brookeld Engineering Labs., Inc. Page 93 Manual No. M13-167-A0415

A.4 Verifying Calibration

1. Determinetheappropriatesamplevolume.RefertoTableA-1todeterminethecorrectsample

volumerequiredforthespindletobeutilized.

2. SelectaBrookeldViscosityStandarduidthatwillgiveviscosityreadingsbetween10%and

100%offullscalerange.RefertoAppendix Bforviscosityrangesofconespindles.

BrookeldusesmineraloilviscositystandarduidstocalibrateWellsBrookeldCone/Plate

Rheometersatthefactory. Brookeld recommends that customers use mineraloilviscosity

standarduidswhenyouperformacalibrationcheck.

Ifyoudecidetouseasiliconeviscositystandarduid,donotuseauidwithaviscosityvalue

greaterthan5000cPwithaCone/Plate.Brookeldoffersacompleterangeofmineraloilviscosity

standardssuitableforusewithCone/Platesforviscositiesabove5,000cPorshearratesabove

500 sec

-1

;seeTableE-2inAppendixFforalistofavailableuids.

Itisbesttouseaviscositystandarduidthatwillbeclosetothemaximumviscosityforagiven

conespindle/speedcombination.

Example: DV3TLVRheometer,ConeSpindleCPA-42Z,BrookeldSiliconeViscosityStandard

havingaviscosityof9.7cPat25°C

At60RPM,thefullscaleviscosityrangeis10.0cP.Thus,theRheometerreadingshouldbe

97%torqueand9.7cPviscosity±0.197cP.Theallowableerror(±0.197cP)isacombination

ofRheometeraccuracyanduidtolerance(refertoInterpretation of Calibration Test Results

inAppendixF).

3. Withthemotoroff,removethesamplecupandplacetheviscositystandarduidintothecup.

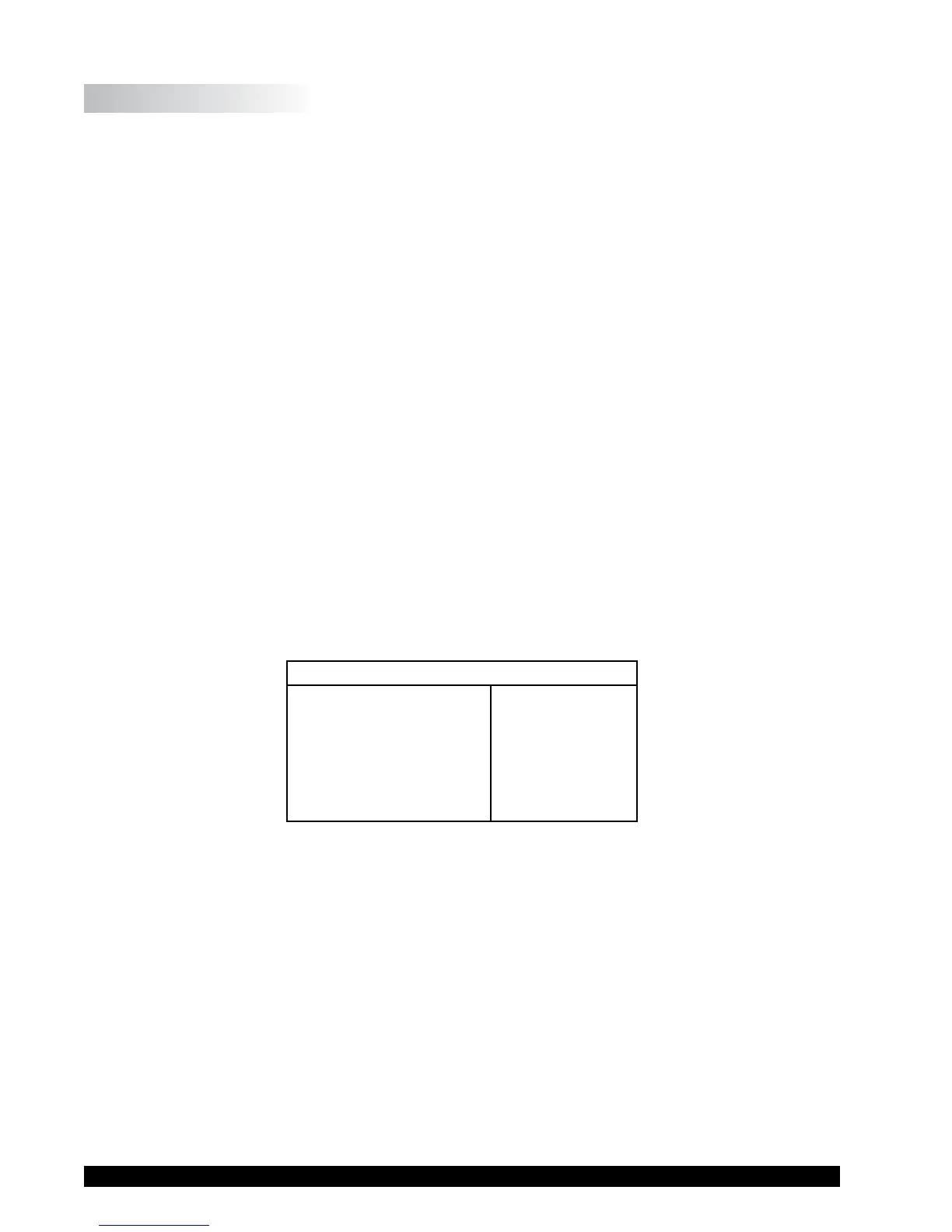

Table A-1

Cone Part No.

CPA-40Z, CPE-40, CP-40

CPA-41Z, CPE-41, CP-41

CPA-42Z, CPE-42, CP-42

CPA-51Z, CPE-51, CP-51

CPA-52Z, CPE-52, CP-52

Sample Volume

0.5 mL

2.0 mL

1.0 mL

0.5 mL

0.5 mL

4. AttachthesamplecuptotheRheometerandallowsufcienttimeforthesample,cupandcone

toreachtemperatureequilibrium.

5. Turnthemotoron.Setthedesiredspeed(s).Measuretheviscosityandrecordthereadingin

both%torqueandcentipoise(cP).

6. Verifythattheviscosityreadingiswithintheallowable1%deviation,asexplainedearlier,for

thespecicviscositystandarduid(s)thatyouareusing.

TheCPEorCPAdesignationontheconespindleindicatesusewithElectronicGapSettingCone/

PlateRheometers/Rheometersonly.

Loading...

Loading...