3 - 29

Rotary hook drive mechanism

Main unit

Assembly

4

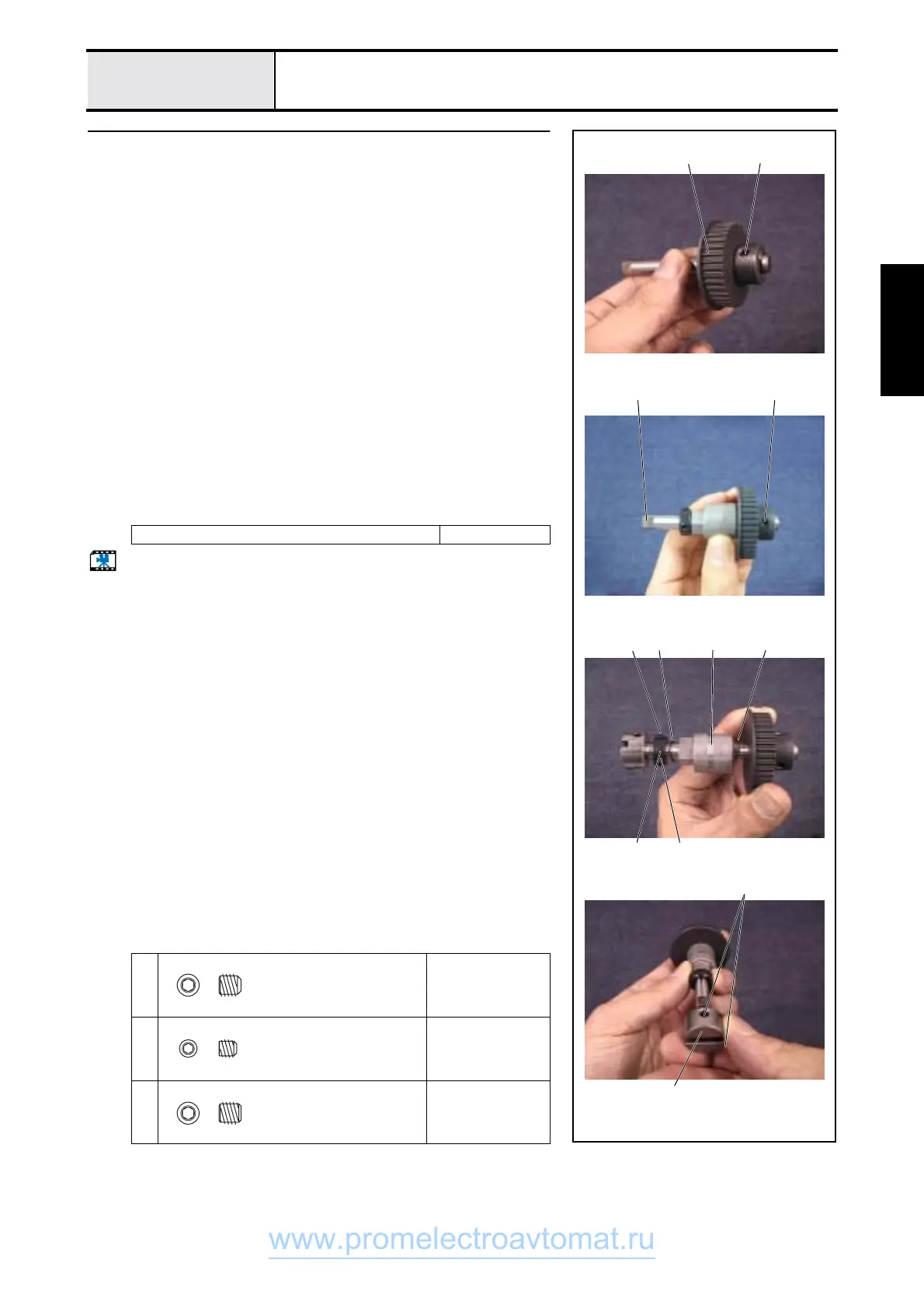

Lower shaft A assy. assembly

1. Attach retaining ring E6 to lower shaft A.

2. Attach timing pulley D 1 to lower shaft A using screws 1 (set screw,

socket (CP) M5X5) (three)

*Key point

• Hand start screw 1, and fully tighten after 4 - 8 "Needle bar

rise adjustment."

• Align one of the three screw holes 3 in timing pulley D with

the D cut 2 in lower shaft A.

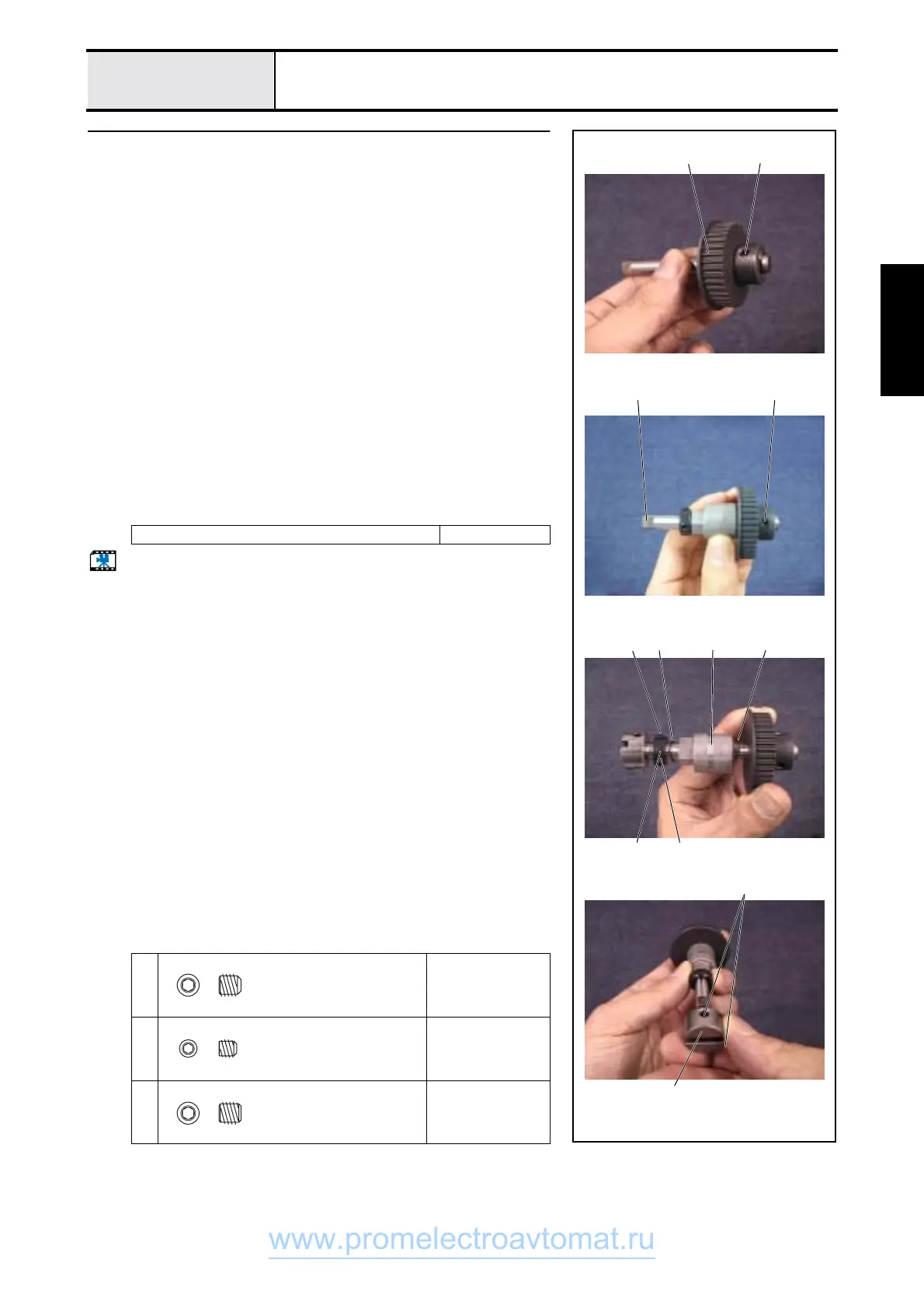

3. Attach the thrust washer 4, eccentric shaft bushing 5, thrust washer 4,

set screw collar 6 to lower shaft A, and secure the set screw collar 6 with

screws 2 (set screw, socket (CP) M4X4) (two).

*Key point

• Ground surface of the set screw collar toward the eccentric

shaft bushing.

4. Apply 1 – 2 drops of Sewing Lube to the eccentric shaft bushing 5.

5. Attach the joint 7 to lower shaft A using screws 3 (set screw, socket (FT)

M5X5) (two).

*Key point

• Joint groove parallel to D cut in lower shaft A

Start movie clip (CD-ROM version only)

Sewing Lube 1 – 2 drops

1

Torque

Hand start

2

Torque

0.78 - 1.18 N-m

3

Torque

1.18 - 1.57 N-m

1 1

6

7

2 454

3

2

12

Set Screw, Socket (CP

M5X5

Color; Black

Set Screw, Socket (CP

M4X4

Color; Black

Set Screw, Socket (FT)

M5X5

Color; Black

www.promelectroavtomat.ru

Loading...

Loading...