3 - 30

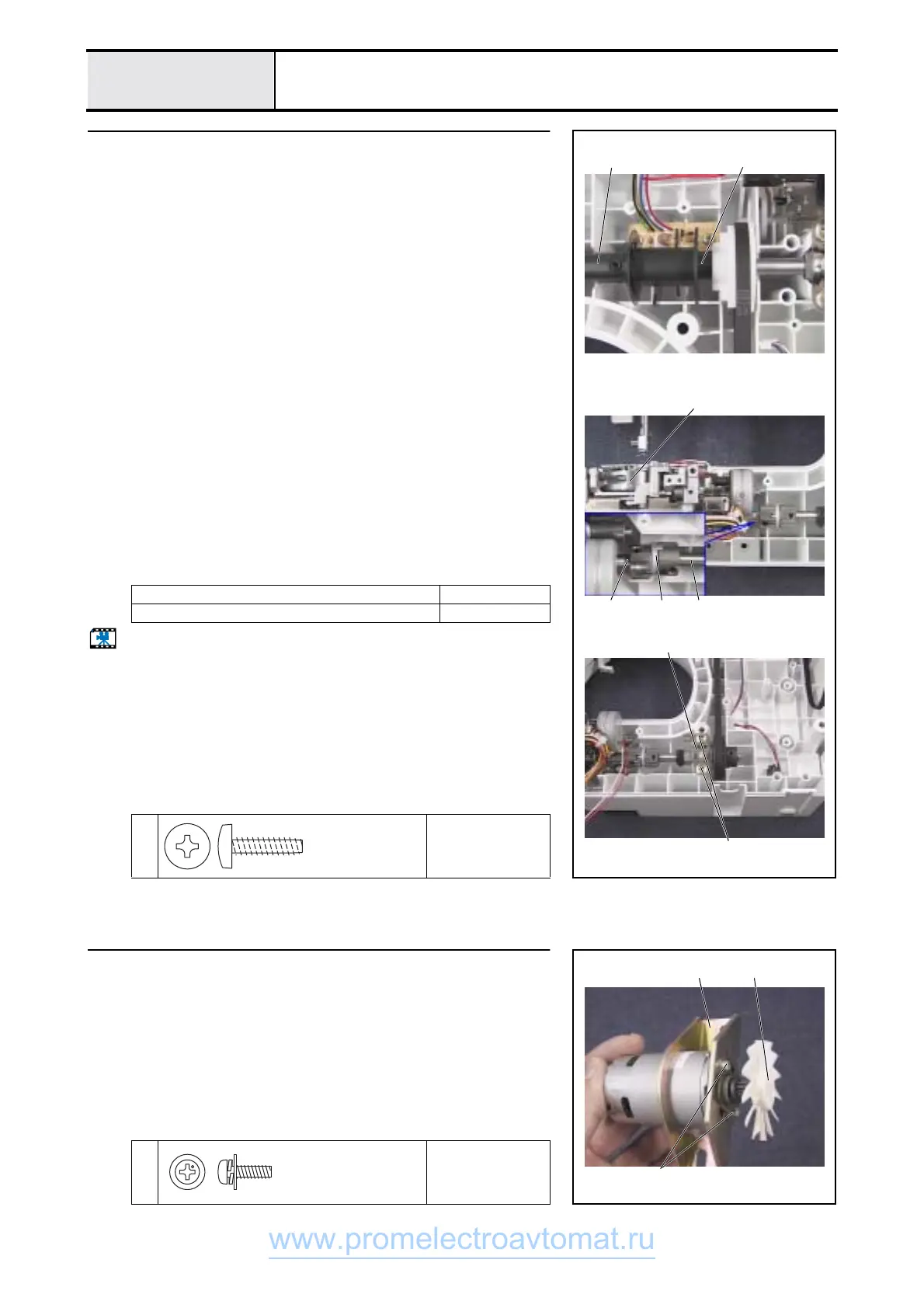

Rotary hook drive mechanism

Main unit

5

Lower shaft A attachment

1. Rotate the upper shaft by hand, and bring the needle bar to its highest point

(timing shutter base line forward).

2. Rotate the feed module lower shaft B, and bring the solid dot 1 on the

outer rotary hook to the front and the D cut on lower shaft B to face straight

up.

3. Apply a small amount of Epnoc Grease AP to lower shaft A and the (feed

module) lower shaft B joint.

4. Place the timing belt (rotary hook drive) on the lower shaft A assy. timing

pulley, and attach the lower shaft A assy. 2 and the disk 3.

*Key point

• The needle bar should be at the highest point.

• The solid circle mark on the outer rotary hook should be

forward.

• The lower shaft B socket set screw (feed module) should be

straight up.

• The lower shaft A side joint socket set screw should face

forward.

5. Attach the lower shaft bushing presser (4) to the arm bed and hand start

screws 1 (two).

*Key point

• Fully tighten after 4 - 7 "Timing belt tension adjustment."

6. Apply 1 – 2 drops of Sewing Lube to the lower shaft assy. eccentric shaft

bushing shaft hole.

Start movie clip (CD-ROM version only)

Epnoc Grease AP Small amount

Sewing Lube 1 – 2 drops

1

Torque

1.18 - 1.57 N-m

1

Base line

4

23

D cut

1

Upper shaft

Giza Tite

5X16

Color; Gold

6

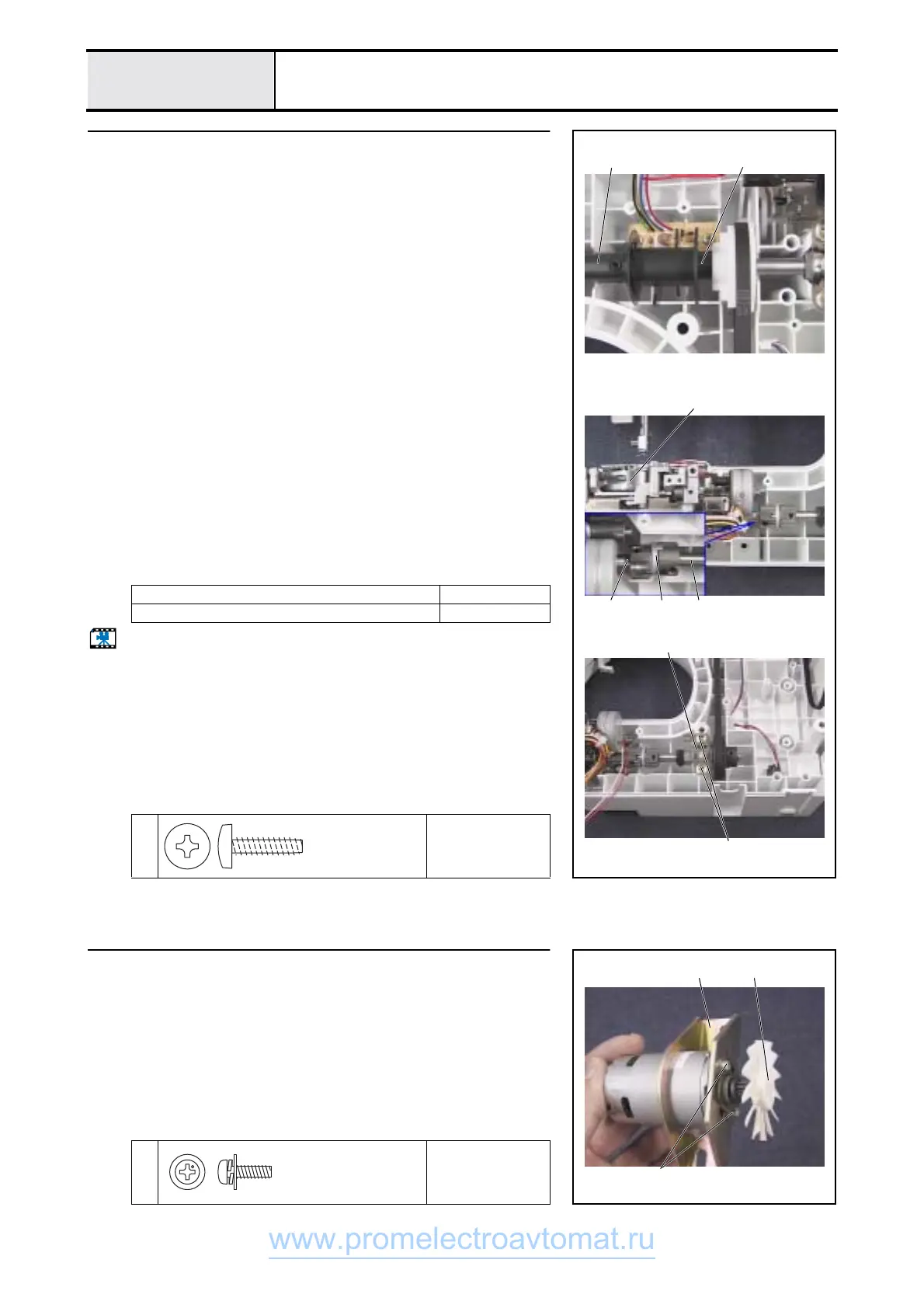

Main motor assy. assembly

1. Attach the main motor to the motor holder 1 using screws 1 (two).

2. 2Attach the motor fan to the main motor.

1

Torque

0.78 - 1.18 N-m

2

1

1

Screw, Pan (S/P washer)

M3X10DB

Color; Silver

www.promelectroavtomat.ru

Loading...

Loading...