3 - 61

Needle-presser module

Modules

Assembly

22

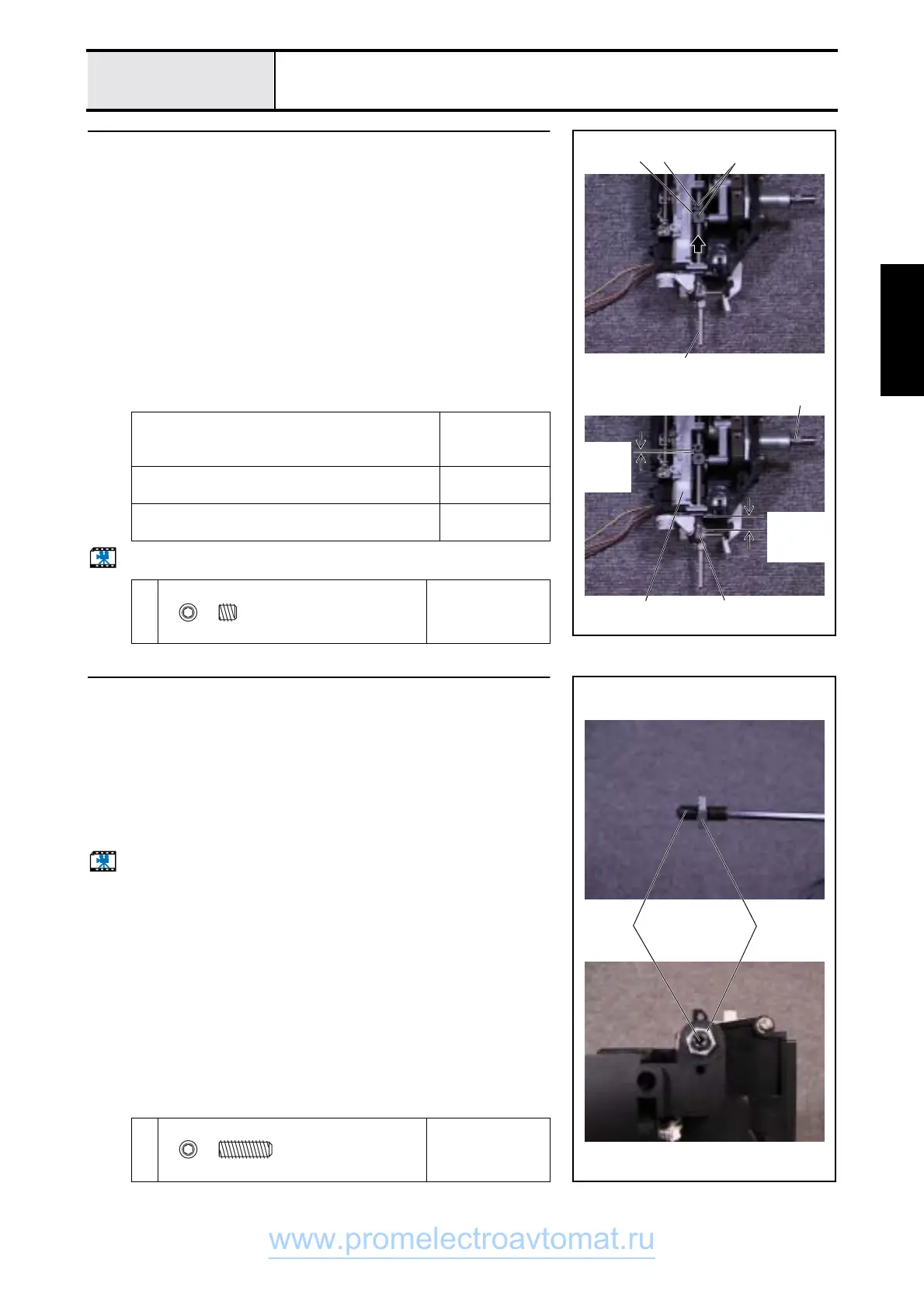

Needle bar assembly attachment

1. Apply a small amount of Epnoc Grease AP to the needle thread block 1.

2. Attach the needle bar 2 to the needle bar crank rod assy. needle bar block

3 and the needle thread block 1, and hand start screws 1 (two).

(Fully tighten after 4 - 9 "Needle bar height adjustment," and 4 - 23"Adjust

the needle thread block.")

*Key point

• With the unit shaft D cut

4

facing forward, the upper surface of the

needle block

5

and the base of the needle bar supporter assy.

6

should be adjusted to an approximately 10 mm separation.

• Adjust the space between the needle thread block 1 and the

needle bar block 3 to approximately 2 mm.

• When the needle thread block 1 is viewed from the front, it is

secured in a position turned slightly counterclockwise (see 4 -

23 "Adjust the needle thread block").

Start movie clip (CD-ROM version only)

Lubricate the needle bar block needle bar crank

joint area on the needle bar block with Molykote

(Sewing Lube 90% + Molykote dispersion)

1 – 2 drops

Apply Epnoc Grease AP to the pin sliding part of

the needle thread block.

Small amount

Lubricate the needle bar supporter assy. needle

operating area with Sewing Lube.

1 – 2 drops

1

Torque

Hand start

3 1

Approxima

tely 2 mm

between 1

and 3

4

6

Approximate

ly 10 mm

between 5

and 6

2

5

1

Set Screw, Socket (FT)

M4X4

Color; Black

23

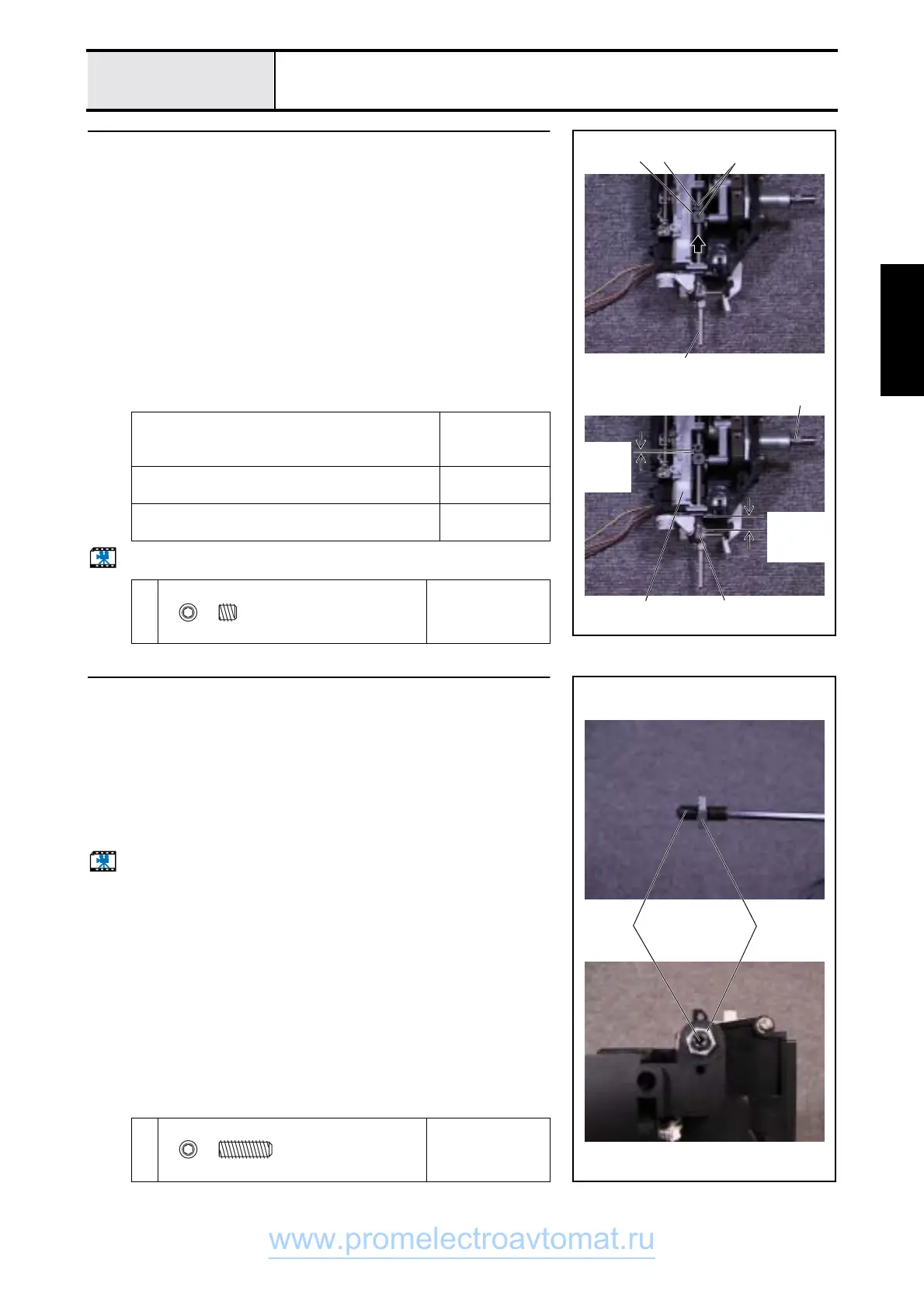

Lock nut attachment

1. Install screw 1 in the locknut 1.

*Key point

• Screw the screw 1 in approximately half its length.

2. Install 1 in the upper unit holder.

*Key point

• Tighten until the lock nut 1 hits the upper unit holder.

3. Tighten the lock nut 1.

Start movie clip (CD-ROM version only)

1

Torque

0.39 - 0.49 N

−

m

1

1

Set Screw, Socket (CP

M4X12

Color; Black

www.promelectroavtomat.ru

Loading...

Loading...