38

Installation

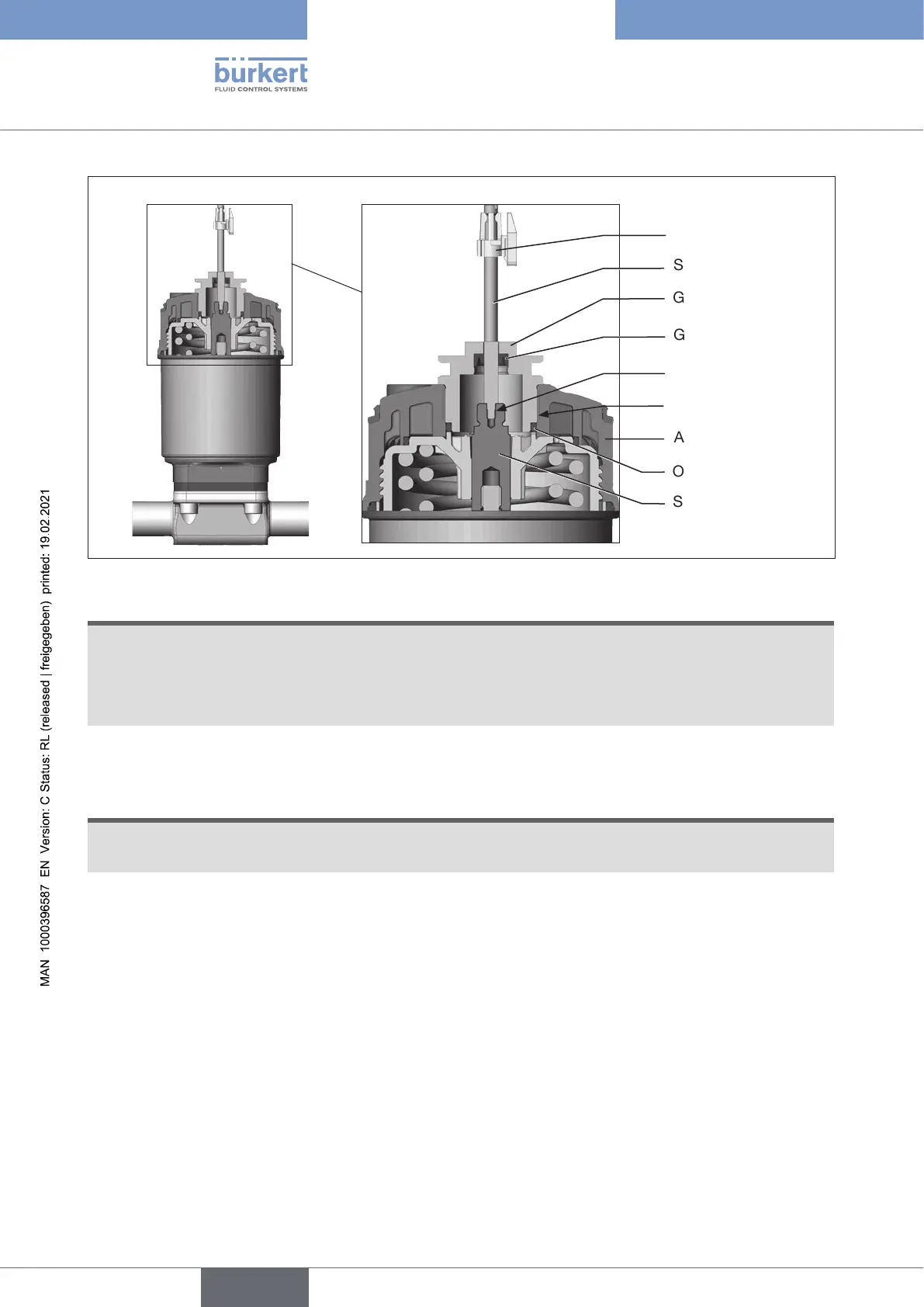

Spindle extension

Guide element

Actuator cover

Groove ring

Puck

Switch spindle

max. 5 Nm

max. 1 Nm

O-ring

Figure 19: Installation of the switch spindle (2), series 2103, 2300 and 2301

ATTENTION!

Improperinstallationmaydamagethegrooveringintheguideelement.

Thegrooveringisalreadybepre-assembledintheguideelementandmustbe“lockedintoposition”

intheundercut.

▶ When installing the switch spindle, do not damage the groove ring.

→ Push the switch spindle through the guide element.

ATTENTION!

Screwlockingpaintmaycontaminatethegroovering.

▶ Do not apply any screw locking paint to the switch spindle.

→ To secure the switch spindle, apply some screw locking paint (Loctite 290) in the tapped bore of the spindle

extension in the actuator.

→ Check that the O-ring is correctly positioned.

→ Screw the guide element to the actuator cover (maximum torque: 5 Nm).

→ Screw switch spindle onto the spindle extension. To do this, there is a slot on the upper side

(maximum torque: 1 Nm).

→ Push puck onto the switch spindle and lock into position.

english

Type 8694 REV.2

Loading...

Loading...