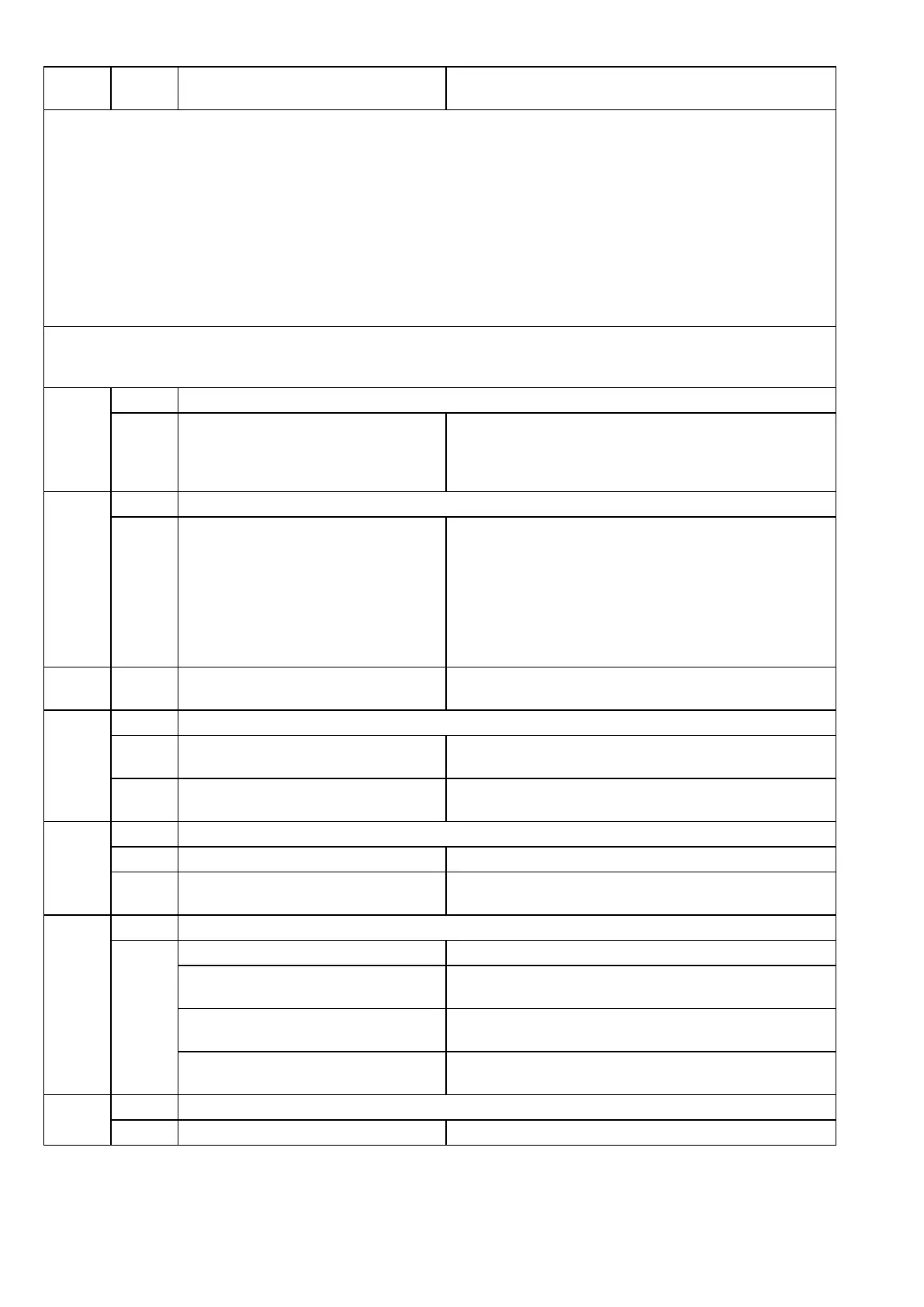

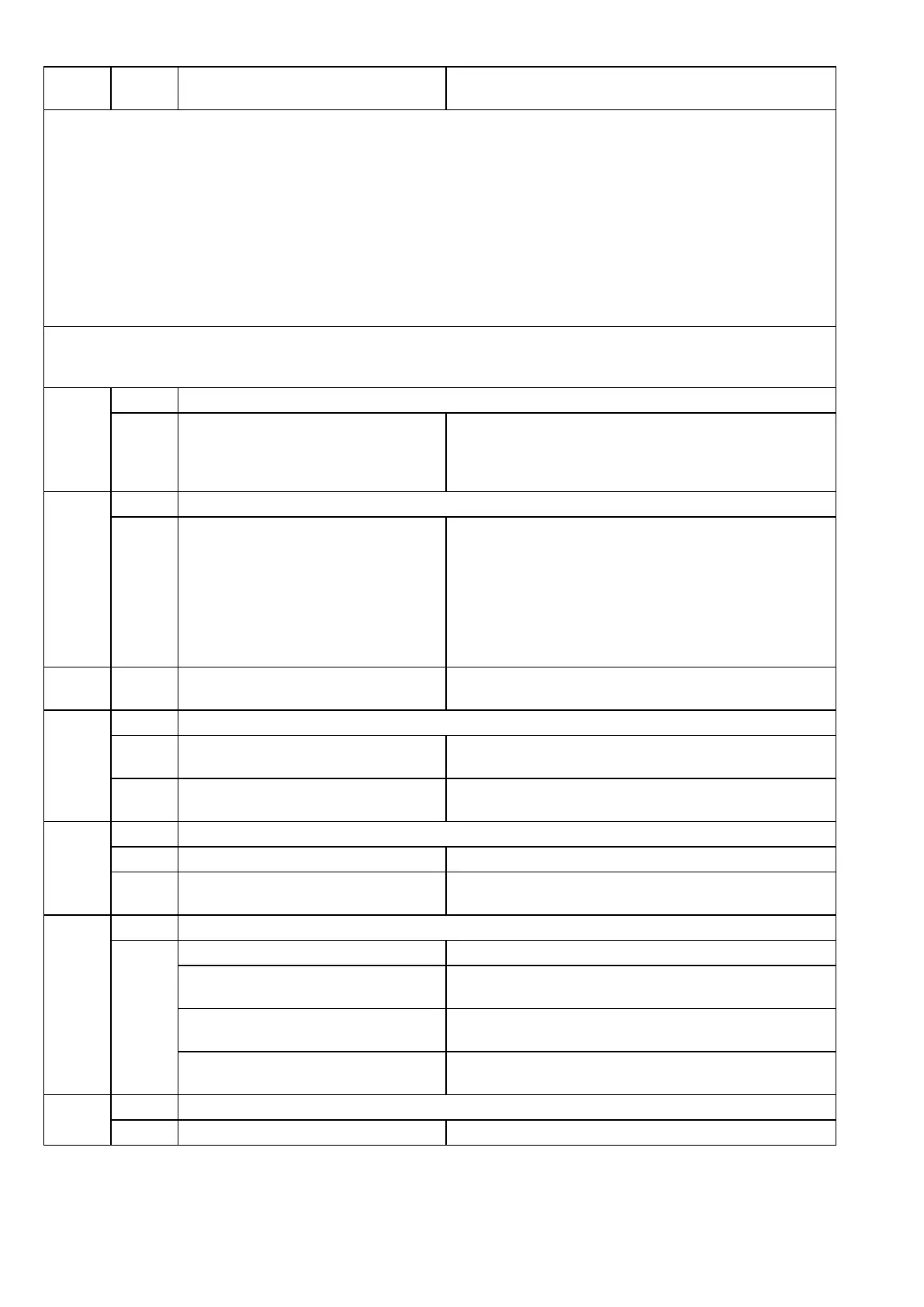

62-61753-21

38 CHECK HIGH SPEED RPM

TRIGGER-ON:

"Check Engine RPM Sensor" alarm not active (if so, refer to alarm 130 first) and:

the microprocessor is calling for high speed and speed being read is less than 1650 or greater than

2075 for more than 60 seconds (120 seconds when the microprocessor calls for a change from low

speed to high speed, or when the unit first starts)

UNIT CONTROL: Engine operation: Shutdown and alarm.

Standby operation: Will not activate in standby.

RESET CONDITION: Auto Reset if the engine speed is within 1670 to 2050 for 60 seconds or alarm

may be manually reset via keypad or by turning the unit off, then back on again.

NOTE: Follow the steps below until a problem is found. Once a repair or correction has been made, the active

alarm should clear itself (refer to reset condition above). Operate the unit through the appropriate modes to see if

any active alarm occurs. Continue with the steps below as necessary.

a. Verify that the model number on

the Unit Data label matches the

model number shown in the Micro-

processor Unit Data list.

Configure the unit for the correct model number. (Refer

to Section 5.1.1.)

Force High Speed Operation

a. Place unit in continuous run and

adjust set point to at least 15 de-

grees away from refrigerated com-

partment temperature, and a tem-

perature greater than 5.6°C (20°F).

If the unit does not immediately go

into High Speed, set the AIRFLOW

Functional Parameter to HIGH.

The microprocessor will call for High Speed operation.

b. Check Speed Relay LED27.

LED27 must be ON. (If LED27 is not on, the micropro-

cessor is not calling for High Speed.)

a. Check actual engine speed using

hand held tachometer.

Refer to Section 2.8.

Adjust engine linkage setting as needed.

b. Compare actual speed with those

shown on display.

Both readings within ± 50 RPM.

Check Engine Air-Intake System

b. Inspect air intake system.

Hoses & tubes in good condition.

No kinks or restrictions.

a. Check fuel tank level.

Must have enough fuel to run engine.

Connections are tight and not leaking.

No kinks or sharp bends in the lines.

Fuel screen is located in the inlet fitting to the lift pump.

Screen must be clean.

Fuel filters must be clean and allow full flow of fuel

through them.

Check Engine Exhaust System

a. Inspect the exhaust system.

Must be clear and unobstructed.

Loading...

Loading...