THE SMART SOLUTION FOR ENERGY EFFICIENCY

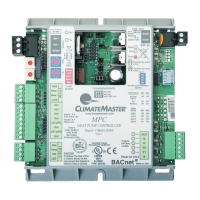

MPC MultiProtoCol DDC Controls

November 19, 2018

19

Water -to-Water Start Up Check

1. Unit powered up and running.

2. LED check: Rx, Tx, Power, Run and no solid

red error led.

3. Program initializing schedule status for Occupied

Mode (default) or Unoccupied Mode to determine

set point range. Occupied set points will be

defaulted to 60 cooling and 105 heating. If a

schedule is implemented, the unoccupied set points

will default to 80 cooling and 85 heating.

4. The Program will determine if the unit is either a

Master or Slave.

5. The Program will control the water temperature

based on the Entering Water Temperature (EWT)

load sensor. This can be changed to control based

off of the LWT via BAS or BACview6 service tool.

6. The Program will check for which water temperature

set point to use based on Heating Mode or Cooling

Mode determined by the state of the RV.

7. In a water to water application, the mode has to be

manually changed via Bacnet or with BACVIEW6

service tool. If it is in heating, it will permanently stay

in heating mode until it is changed to specically

cooling mode.

8. Like water to air, Y1 will come on a 50% and Y2 at

75% and not off until the EWT/LWT conditions have

been satised.

9. 5-minute delay is built in between compressor cycles.

10. While the unit is on, the program will continue to

monitor the CXM/DXM/DXM2 board for faults. If

an event of a fault occurs and the unit is in lockout

mode, then the relay will close (IN1/AL1/AL2/GND)

and the fault code is transmitted via EH2 output to

the EHZ input on the MPC. This is available through

BAS network points. A history counter will also keep

track of past and present faults which can also be

seen via BAS or BACview6.

11. The MPC can also function in metric mode

(Celsius mode).

MPC Sequence of Operation

Water-to-Air Startup Check-

Equipment Touch Method

1. Unit is Powered up?

YES: Go to step 2

NO: Apply power to MPC.

2. Check Led status.

a. Green (TxD) LED should be blinking rapidly.

b: Green power LED should be on solid .

c: Green RUN LED should be blinking at 1-2

blinks per second.

d: RED error LED should be off.

YES: Go to step 3.

Power down MPC and wire up the Equipment Touch

Service Tool and RNet Sensor(s). Once these are

installed, power MPC back up.The Equipment Touch

should power up and display the “Main” (Home)

3. Navigate to the “Sensor Setup and Status” screen

by pressing <MPC Setup/Status> then <Sensor

Setup/Status> buttons. Press the <ZS Sens Active>

button. This should display the correct address and

number of ZS Sensors that are attached to the MPC.

Press the <Back> and go to the “ZS Sensor Setup”

screen where you will need to enable the alarms for

each sensor installed and detected in the previous

step.

4. From the EQT menu press <Temp Setup and

Status> then press <Temp Units>. “Current Mode”

should be set to <Fahrenheit>. If this is ok, you are

nished here and can move on to Step 5. Otherwise

uncheck the “Metric Mode” (BV:39) point to set the

MPC to Fahrenheit mode. Make sure the “Current

Mode” changes to “FAHRENHEIT” before pressing

<BACK> and exiting this screen.

Figure 16: Menus screen

Loading...

Loading...