Menu 4

Parameter

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Performance

64 Mentor MP Advanced User Guide

www.controltechniques.com Issue Number: 4

The proportional gain Kp (Pr 4.13) is the most critical value in controlling the performance of the current controllers. The value can be set by auto-

tuning (see Pr 5.12 {SE13, 0.34}).

Pr 4.14 = 1697 x L x f x Imax / V rms

Where :

L is the load inductance in Henries

R is the load resistance in ohms

f is the supply frequency in Hertz

Imax is the peak load current (including any overload) in amps

V rms is the line-to-line supply voltage in volts.

The gain values that are calculated by the autotune system give the best response with minimal overshoot. If required the gains can be adjusted to

improve performance as follows:

1. The integral gain (Ki) can be used to improve the performance of the current controllers by reducing the effects of non-linearity. These effects will

be more significant for drives with higher current ratings and higher voltage ratings. If Ki is increased by a factor of 4 it is possible to get up to

10 % overshoot in response to a step change of current reference. For high performance applications, it is recommended that Ki is increased by

a factor of 4 from the autotuned values.

2. It is possible to increase the proportional gain (Kp) to reduce the response time of the current controllers. If Kp is increased by a factor of 1.5 then

the response to a step change of reference will give 12.5 % overshoot. It is recommended that Ki is increased in preference to Kp.

Pr 4.16 = 0 - Drive trips when estimated motor temperature reaches 100 %.

Pr 4.16 = 1 - Drive current limit is limited to 100 % when estimated motor temperature reaches 100 %.

Pr 4.16 = 2 - Drive trips when estimated motor temperature reaches 100 % and accumulator is reset at power-up.

Pr 4.16 = 3 - Drive current limit is limited to 100 % when estimated motor temperature reaches 100 % and accumulator is reset at power-up.

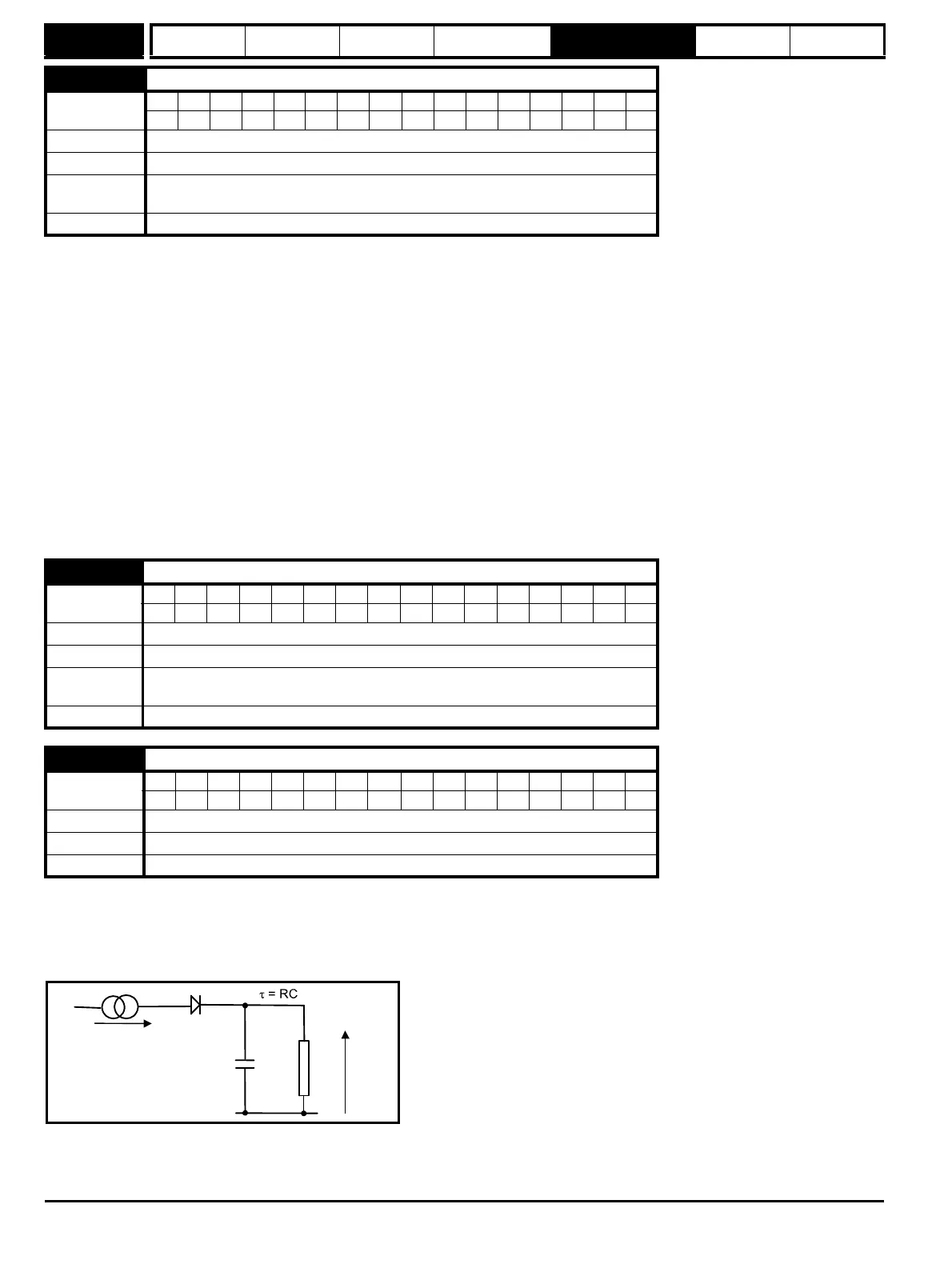

The motor is modelled thermally in a way that is equivalent to the electrical circuit shown as follows.

The temperature of the motor as a percentage of maximum temperature, with a constant current magnitude of I, and constant value of motor rated

current (set by Pr 5.07 {SE07, 0.28} or Pr 21.07) after time t is given by

Temp = [I

2

/ (1.05 x Motor rated current)

2

] (1 - e

-t/τ

) x 100 %

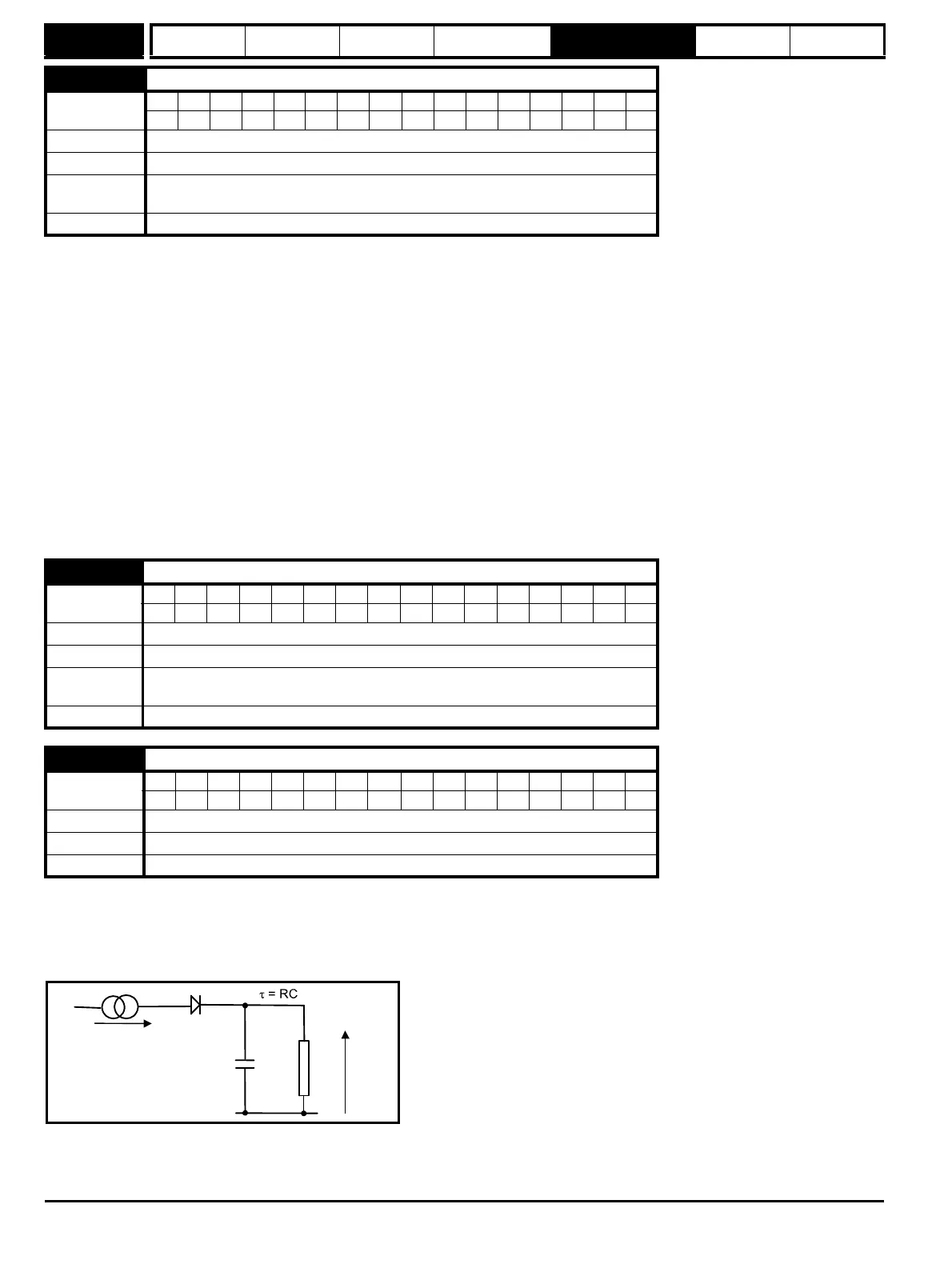

4.14 Continuous current controller Ki gain

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 111

Range 0 to 4000

Default 50

Second motor

parameter

Pr 21.14

Update rate Background read

4.15 Thermal filter

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range 0.0 to 3000.0

Default 89.0

Second motor

parameter

Pr 21.16

Update rate Background read

4.16 Thermal protection mode

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range 0 to 3

Default 0

Update rate Background read

I /(1.05*Motor Rated Current)

22

Tem p

C

R

Loading...

Loading...