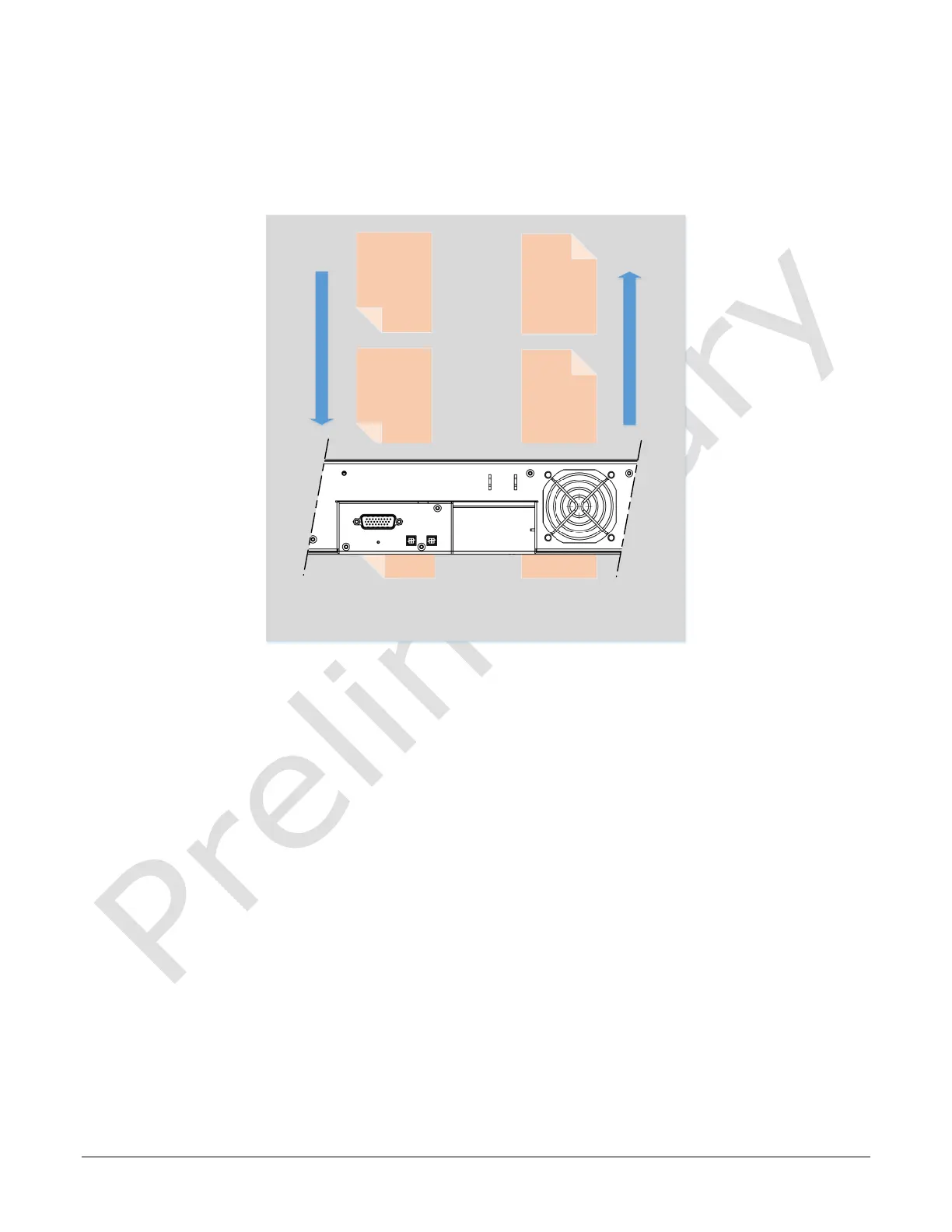

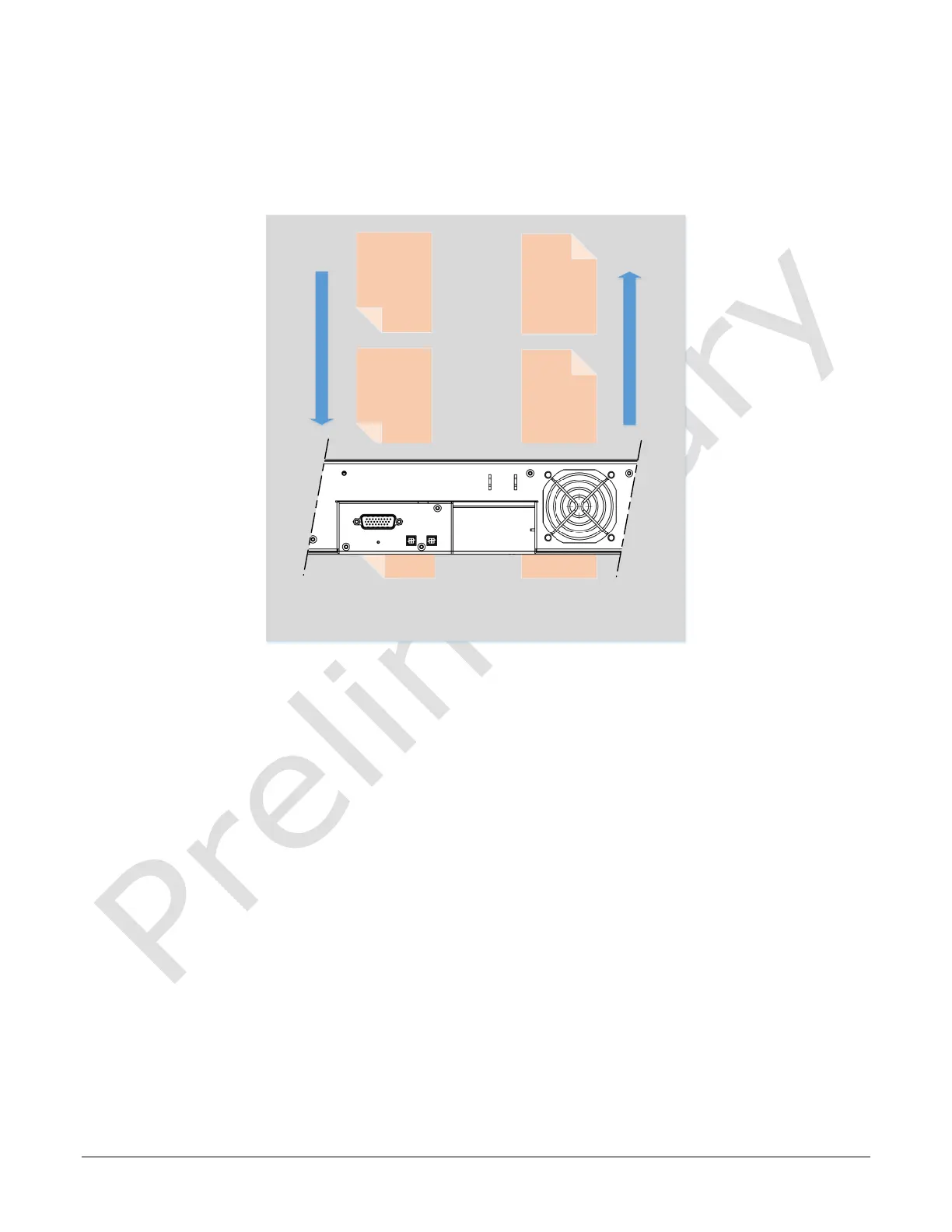

Figure 10: Example of Object Movement and Module Direction

Some inspection systems require that the scan direction change at regular intervals. For example,

scanning a panel forwards, coming to a stop and then scanning backward as the camera’s field of

view is progressively indexed over the entire panel.

It is necessary for the system to over-scan the area being imaged by at least the 64 encoder

(Exsync) pulses before the direction is changed. This ensures that valid data will be generated on

the return path as the modules field of view reaches the area to be inspected.

Automatic Sensor Alignment

Other CIS modules typically comprise a linear array of small sensors butted end to end to provide a

large field of view. Due to the physical characteristics of the sensors, there are lost pixels at the

butt joints which need to be interpolated with associated loss of image quality. To ensure 100%

image coverage, the AxCIS modules use a staggered sensor approach where adjacent sensors

fields of view overlap their neighbors preserving image quality.

Each sensors physical location is accurately measured during the production calibration process

where alignment parameters are sent and stored by the module for use in normal operation. The

module automatically aligns each sensors image data real time in x and y directions to form a

continuous single, aligned image data. Overlap image data is removed.

Loading...

Loading...