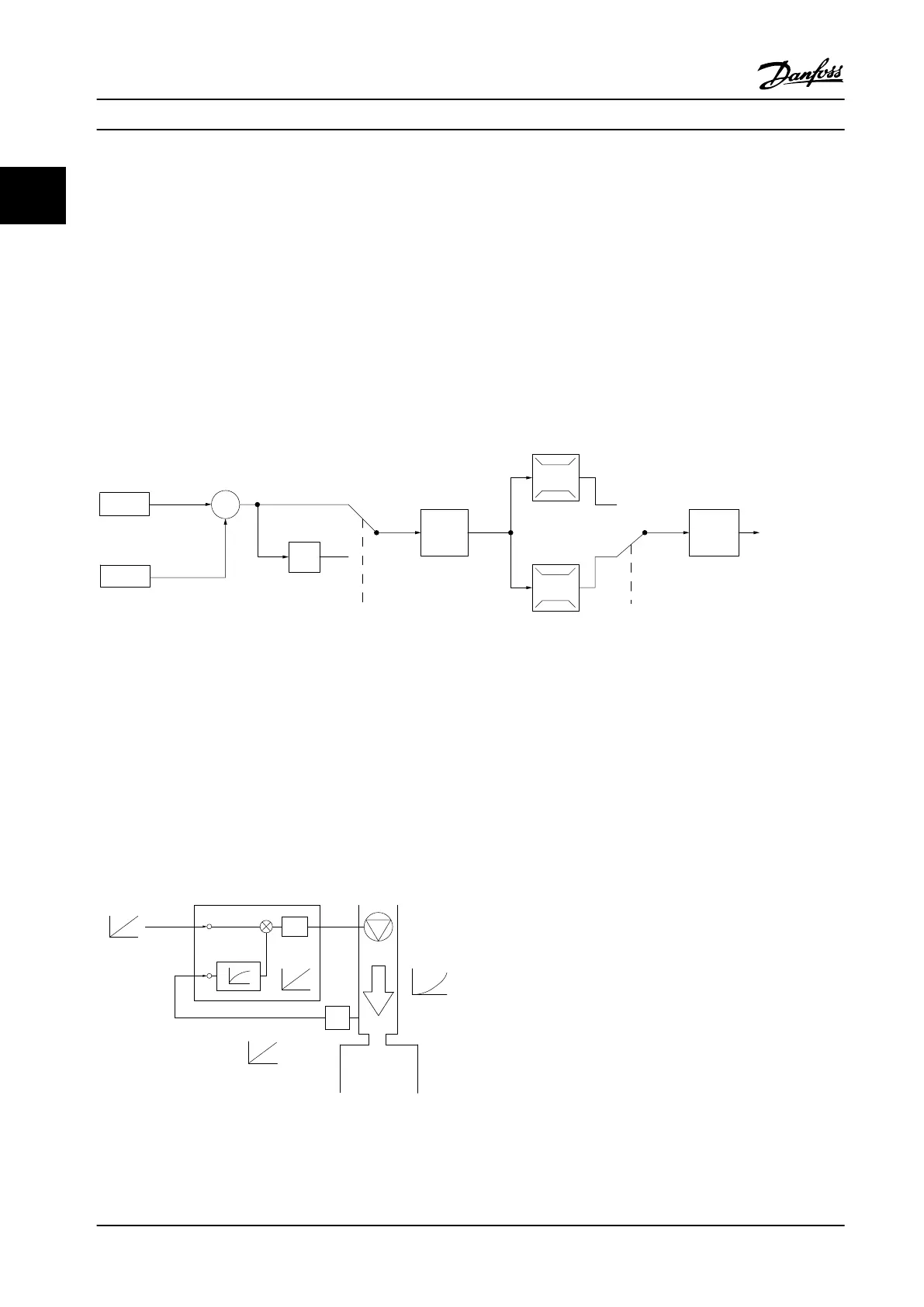

2.7.5 Control Structure Closed-loop

The internal controller allows the adjustable frequency drive to become an integral part of the controlled system. The

adjustable frequency drive receives a feedback signal from a sensor in the system. It then compares this feedback to a

setpoint reference value and determines the error, if any, between these two signals. It then adjusts the speed of the motor

to correct this error.

For example, consider a pump application where the speed of a pump is to be controlled so that the static pressure in a

pipe is constant. The desired static pressure value is supplied to the adjustable frequency drive as the setpoint reference. A

static pressure sensor measures the actual static pressure in the pipe and supplies this to the adjustable frequency drive as

a feedback signal. If the feedback signal is greater than the setpoint reference, the adjustable frequency drive slows down

to reduce the pressure. In a similar way, if the pipe pressure is lower than the setpoint reference, the adjustable frequency

drive automatically speed up to increase the pressure provided by the pump.

7-30 PI

Normal/Inverse

Control

PI

Reference

Feedback

Scale to

speed

P 4-10

Motor speed

direction

To motor

control

130BB894.11

S

100%

0%

-100%

100%

*[-1]

_

+

Figure 2.19 Control Structure Closed-loop

While the default values for the adjustable frequency drive’s closed-loop controller often provides satisfactory performance,

the control of the system can often be optimized by adjusting some of the closed-loop controller’s parameters.

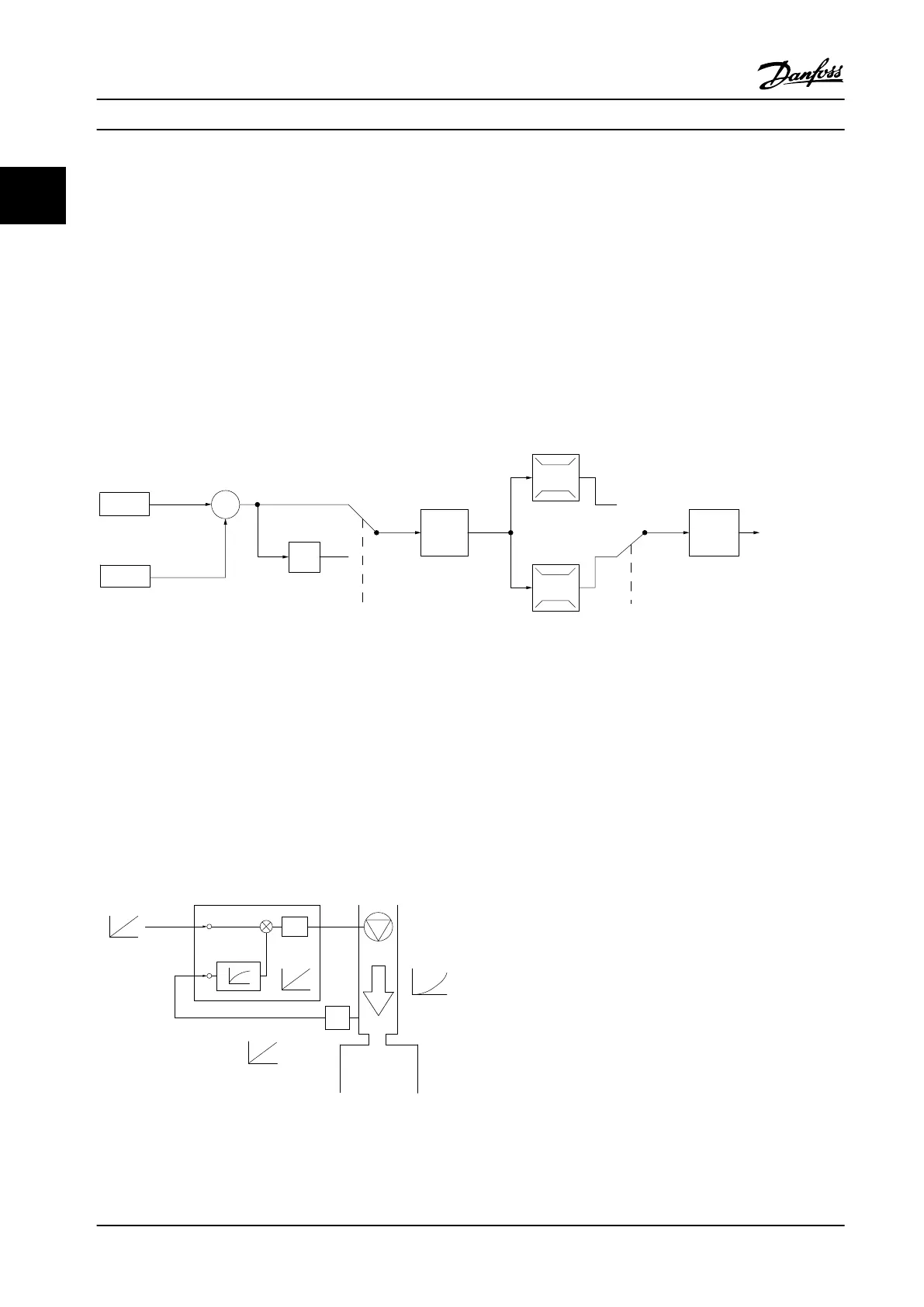

2.7.6

Feedback Conversion

In some applications, it may be useful to convert the feedback signal. One example of this is using a pressure signal to

provide flow feedback. Since the square root of pressure is proportional to flow, the square root of the pressure signal

yields a value proportional to the flow. See Figure 2.20.

130BB895.10

+

-

PI

P

P

P

Ref.

signal

Desired

ow

FB conversion

Ref.

FB

Flow

FB

signal

Flow

P 20-01

Figure 2.20 Feedback Signal Conversion

Product Overview Design Guide

28 Danfoss A/S © Rev. 2014-01-14 All rights reserved. MG18C522

22

Loading...

Loading...