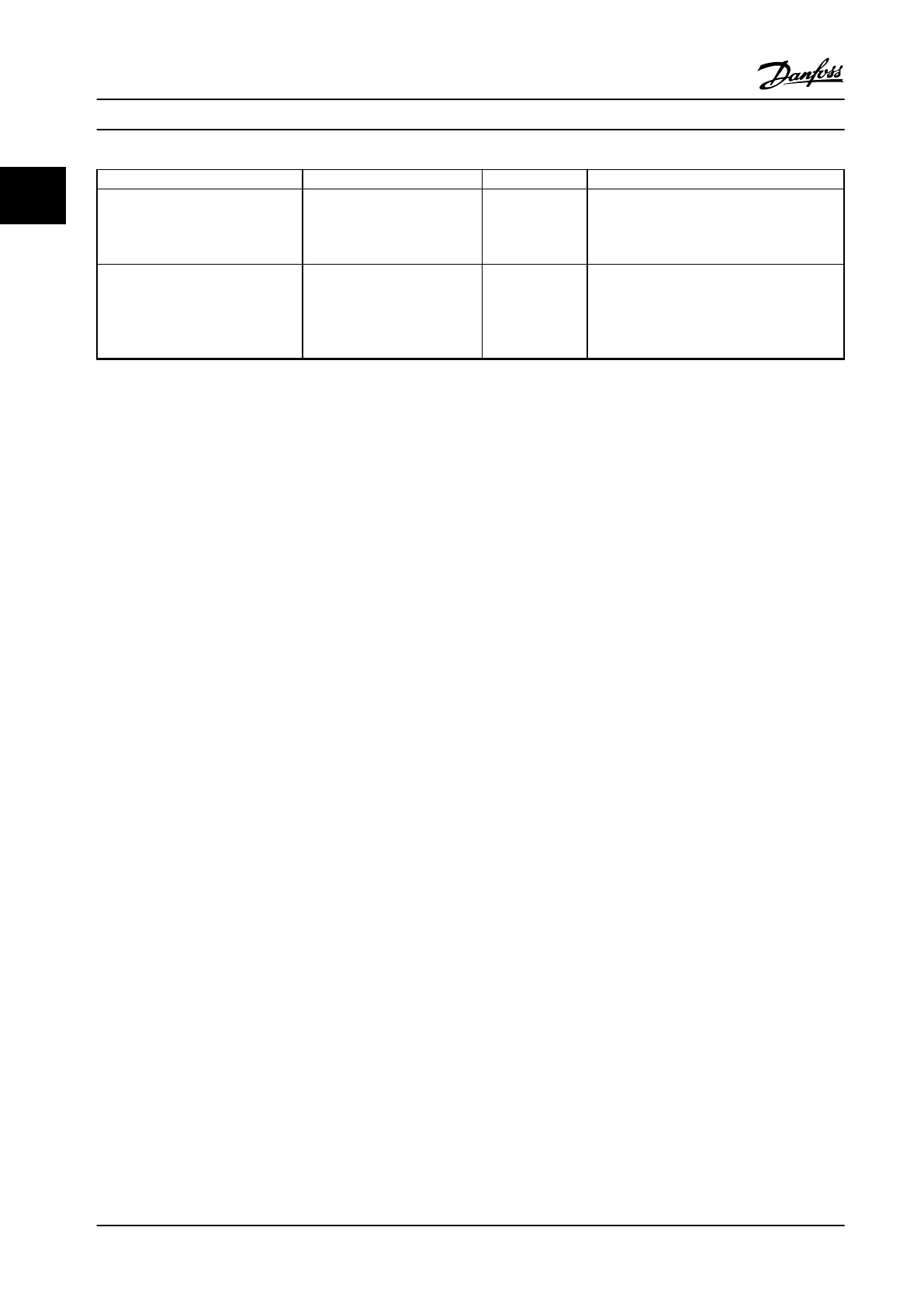

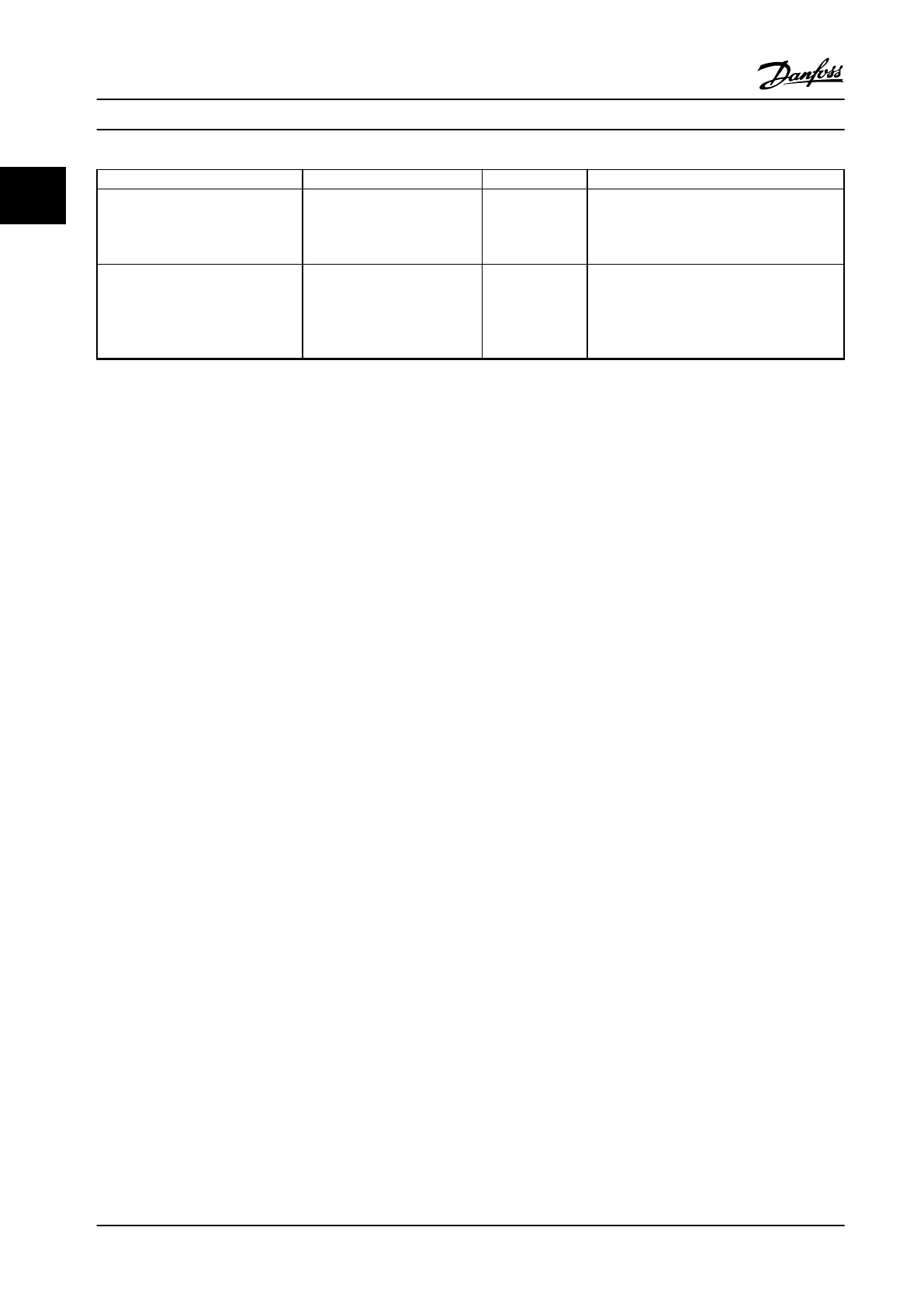

Parameter Range Default Function

20-93 PI Proportional Gain 0–10 0.01 Enter the process controller proportional gain.

Quick control is obtained at high amplifi-

cation. However, if amplification is too great,

the process may become unstable.

20-94 PI Integral Time 0.1–999.0 s 999.0 s Enter the process controller integral time.

Obtain quick control through a short integral

time, though if the integral time is too short,

the process becomes unstable. An excessively

long integral time disables the integral action.

Table 2.8 Closed-loop Set-up Wizard

2.7.9

Tuning the Drive Closed-loop Controller

Once the adjustable frequency drive's closed-loop controller has been set up, the performance of the controller should be

tested. In many cases, its performance may be acceptable using the default values of 20-93 PI Proportional Gain and 20-94 PI

Integral Time. However, in some cases it may be helpful to optimize these parameter values to provide faster system

response while still controlling speed overshoot.

2.7.10

Manual PI Adjustment

1. Start the motor.

2.

Set 20-93 PI Proportional Gain to 0.3 and increase it until the feedback signal begins to oscillate. If necessary, start

and stop the adjustable frequency drive or make step changes in the setpoint reference to attempt to cause

oscillation. Next reduce the PI proportional gain until the feedback signal stabilizes. Then reduce the proportional

gain by 40–60%.

3.

Set 20-94 PI Integral Time to 20 s and reduce it until the feedback signal begins to oscillate. If necessary, start and

stop the adjustable frequency drive or make step changes in the setpoint reference to attempt to cause oscillation.

Next, increase the PI integral time until the feedback signal stabilizes. Then increase of the integral time by 15–

50%.

Product Overview Design Guide

34 Danfoss A/S © Rev. 2014-01-14 All rights reserved. MG18C522

22

Loading...

Loading...