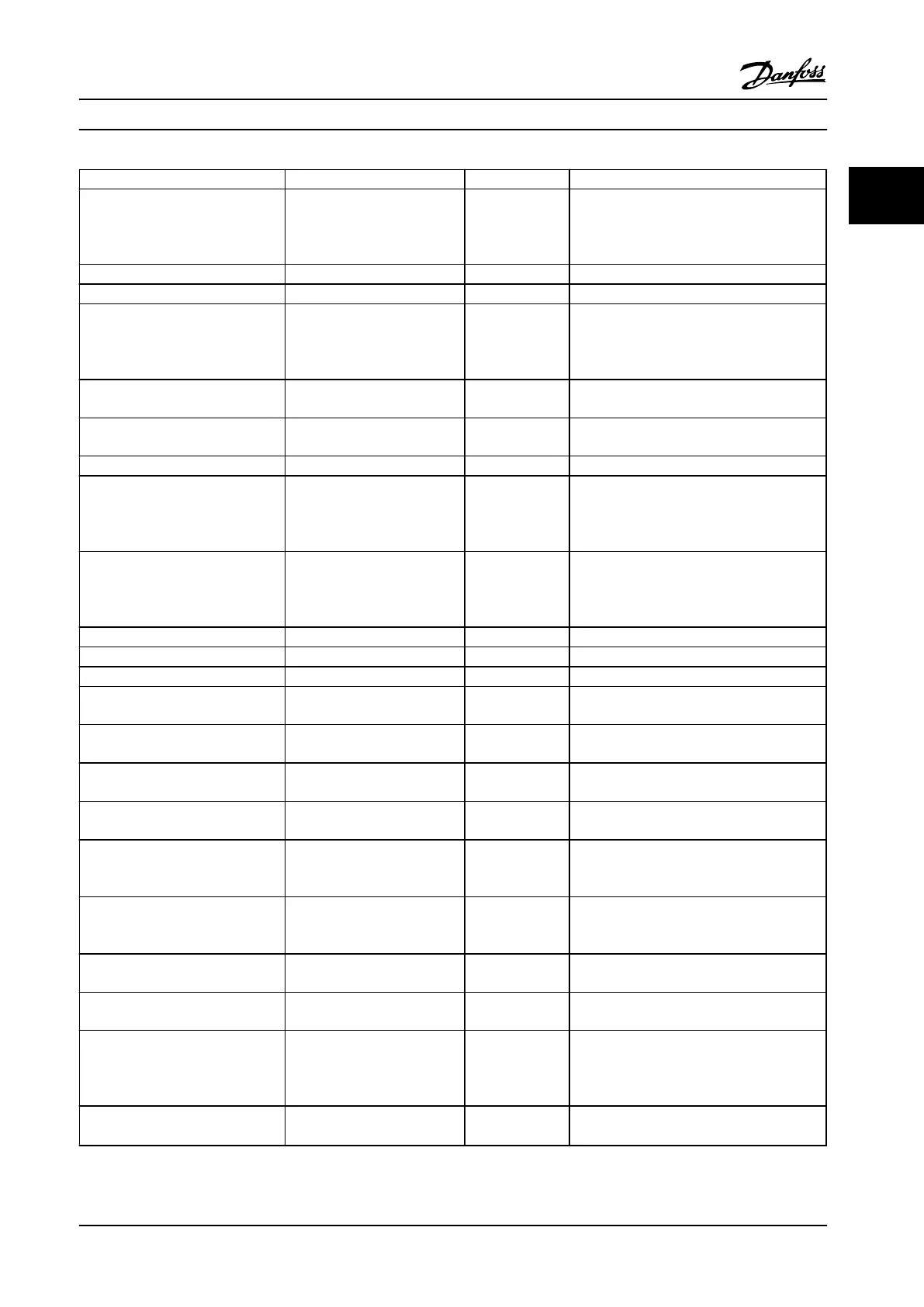

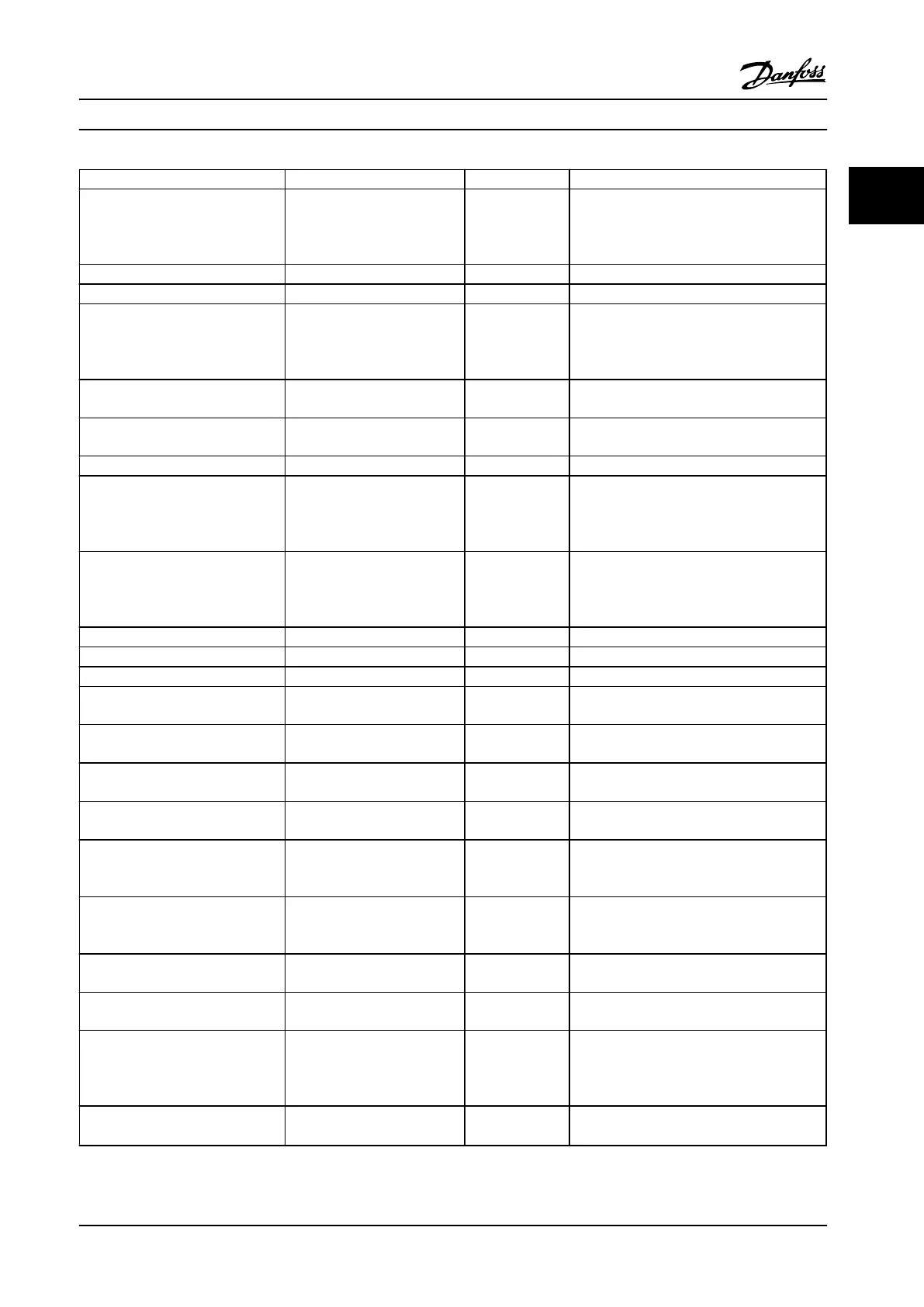

Parameter Range Default Function

1-37 d-axis Inductance (Ld) 0–1000 Size related Enter the value of the d-axis inductance.

Obtain the value from the permanent magnet

motor data sheet. The de-axis inductance

cannot be found by performing an AMA.

1-39 Motor Poles 2–100 4 Enter the number of motor pole.

1-40 Back EMF at 1000 RPM 10–9000 Size related Line-Line RMS back EMF voltage at 1000 RPM

1-73 Flying Start [0] Disabled

[1] Enabled

0

Select [1] Enable to enable the adjustable

frequency drive to catch a spinning motor,

e.g., in fan applications. When PM is selected,

Flying Start is enabled.

3-02 Minimum Reference -4999–4999 0 The minimum reference is the lowest value

obtainable by summing all references.

3-03 Maximum Reference -4999–4999 50 The maximum reference is the highest value

obtainable by summing all references.

3-10 Preset Reference -100–100% 0 Enter the setpoint.

3-41 Ramp 1 Ramp Up Time 0.05–3600.0 s Size related

Ramp-up time from 0 to rated 1-23 Motor

Frequency if Asynchron motor is selected;

ramp-up time from 0 to 1-25 Motor Nominal

Speed if PM motor is selected.

3-42 Ramp 1 Ramp Down Time 0.05–3600.0 s Size related

Ramp-down time from rated 1-23 Motor

Frequency to 0 if Asynchron motor is selected;

ramp-down time from 1-25 Motor Nominal

Speed to 0 if PM motor is selected.

4-12 Motor Speed Low Limit [Hz] 0.0–400 Hz 0.0 Hz Enter the minimum limit for low speed.

4-14 Motor Speed High Limit [Hz] 0–400 Hz 65 Hz Enter the minimum limit for high speed.

4-19 Max Output Frequency 0–400 Size related Enter the maximum output frequency value.

6-20 Terminal 54 Low Voltage 0–10 V 0.07 V Enter the voltage that corresponds to the low

reference value.

6-21 Terminal 54 High Voltage 0–10 V 10 V Enter the voltage that corresponds to the low

high reference value.

6-22 Terminal 54 Low Current 0–20 mA 4 Enter the current that corresponds to the high

reference value.

6-23 Terminal 54 High Current 0–20 mA 20 Enter the current that corresponds to the high

reference value.

6-24 Terminal 54 Low Ref./Feedb.

Value

-4999–4999 0 Enter the feedback value that corresponds to

the voltage or current set in 6-20 Terminal 54

Low Voltage/6-22 Terminal 54 Low Current

6-25 Terminal 54 High Ref./Feedb.

Value

-4999–4999 50 Enter the feedback value that corresponds to

the voltage or current set in 6-21 Terminal 54

High Voltage/6-23 Terminal 54 High Current

6-26 Terminal 54 Filter Time

Constant

0–10 s 0.01 Enter the filter time constant.

6-29 Terminal 54 mode [0] Current

[1] Voltage

1 Select if terminal 54 is used for current or

voltage input.

20-81 PI Normal/ Inverse Control [0] Normal

[1] Inverse

0

Select [0] Normal to set the process control to

increase the output speed when the process

error is positive. Select [1] Inverse to reduce

the output speed.

20-83 PI Start Speed [Hz] 0–200 Hz 0 Enter the motor speed to be attained as a

start signal for commencement of PI control.

Product Overview Design Guide

MG18C522 Danfoss A/S © Rev. 2014-01-14 All rights reserved. 33

2 2

Loading...

Loading...