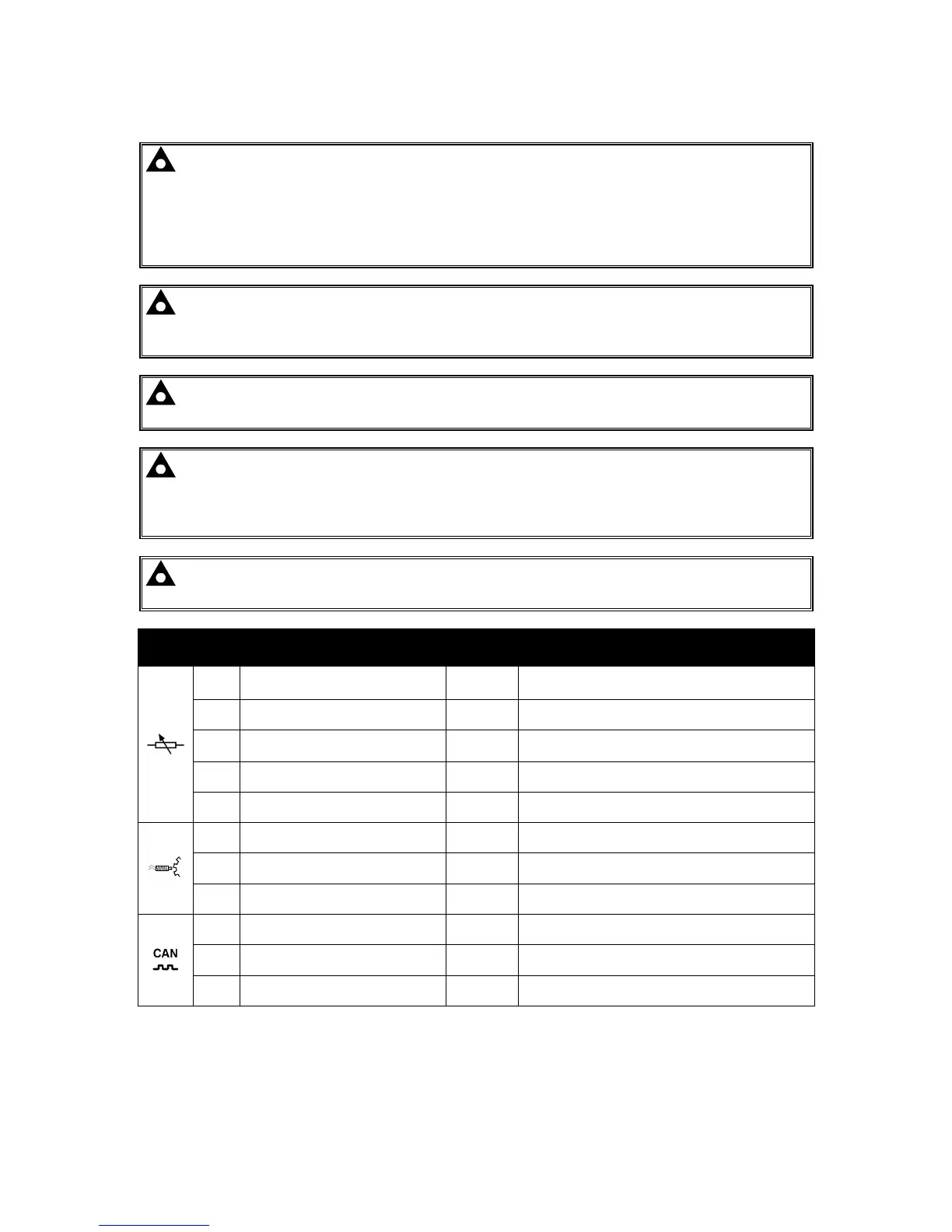

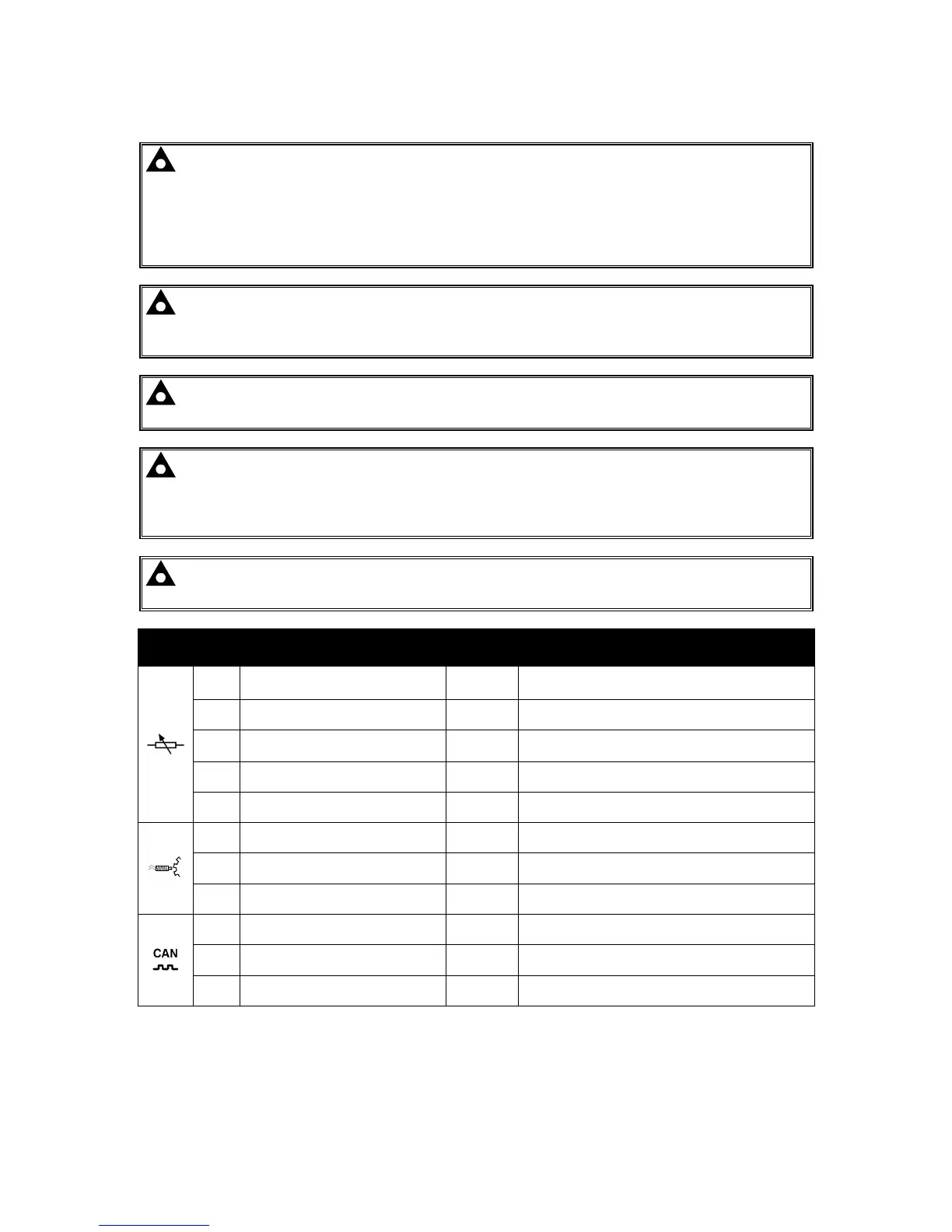

3.1.2 ANALOGUE SENSORS, MPU, CAN

NOTE: It is VERY important that terminal 11 (sensor common) is soundly connected to an

earth point on the ENGINE BLOCK, not within the control panel, and must be a sound

electrical connection to the sensor bodies. This connection MUST NOT be used to provide an

earth connection for other terminals or devices. The simplest way to achieve this is to run a

SEPARATE earth connection from the system earth star point, to terminal 11 directly, and not

use this earth for other connections.

NOTE: If you use PTFE insulating tape on the sensor thread when using earth return

sensors, ensure you do not insulate the entire thread, as this prevents the sensor body from

being earthed via the engine block.

NOTE: For further details on connection to electronic engines, refer to DSE Publication:

057-004 Electronic Engines And DSE Wiring

NOTE: Screened 120 Ω

ΩΩ

Ω impedance cable specified for use with CAN must be used for the

CAN link.

DSE stock and supply Belden cable 9841 which is a high quality 120 Ω

ΩΩ

Ω impedance cable

suitable for CAN use (DSE part number 016-030)

NOTE: For further details of module configuration, refer to DSE Publication: 057-224

DSE6110 MKII & 6120 MKII Configuration Software Manual.

Pin

No

Description

Cable

Size

Notes

11 Sensor Common Return

0.5 mm²

AWG 20

Return Feed For Sensors

12 Oil Pressure Input

0.5 mm²

AWG 20

Connect To Oil Pressure Sensor

13 Coolant Temperature Input

0.5mm²

AWG 20

Connect To Coolant Temperature Sensor

14 Fuel Level Input

0.5 mm²

AWG 20

Connect To Fuel Level Sensor

15 Flexible Sensor Input

0.5 mm²

AWG 20

Connect To Additional Sensor (User Configurable)

16 Magnetic Pickup Positive

0.5 mm²

AWG 20

Connect To Magnetic Pickup Device

17 Magnetic Pickup Negative

0.5 mm²

AWG 20

Connect To Magnetic Pickup Device

18 Magnetic Pickup Screen Shield Connect To Ground At One End Only

19 CAN Port H

0.5 mm²

AWG 20

Use Only 120 Ω CAN Approved Cable

20 CAN Port L

0.5 mm²

AWG 20

Use Only 120 Ω CAN Approved Cable

21 CAN Port Screen Shield Use Only 120 Ω CAN Approved Cable

Loading...

Loading...