V0505, 3.12

3.h

Auxiliary axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .R/Z/Aux.

If you have one or more auxiliary axes (for instance a R-axis, Z-axis or part support) the

parameters of these axes appear here.

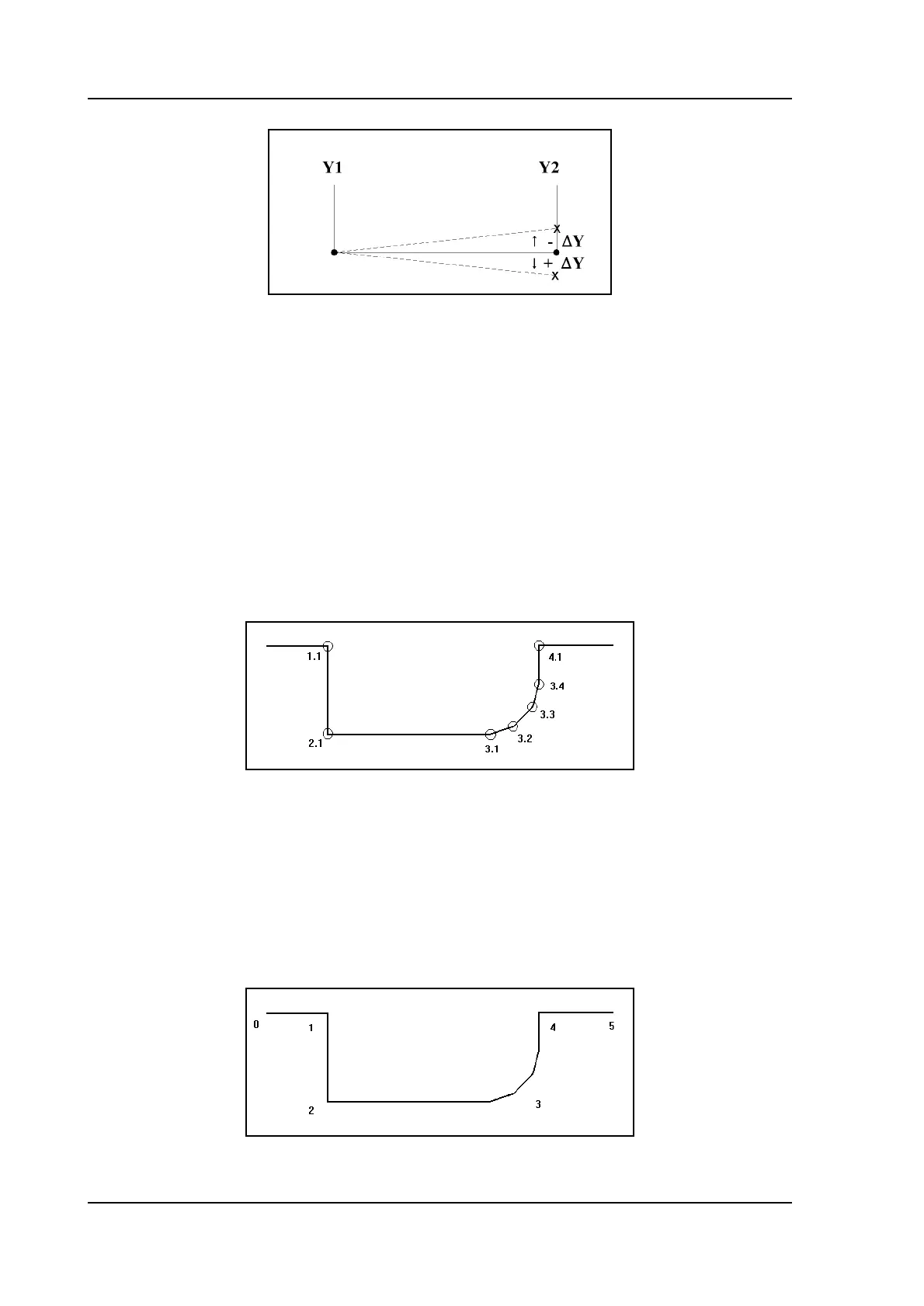

Angle number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AN

The rank number of this angle, when counted from left to right through the product pro-

file (figure 4.j). The digit before the dot describes this rank number, the digit after the dot

descibes the rank number of this bend in case of a bumping sequence.

In case of a normal angle, the bumping number should always be 1. In the case of a

radius bend, all bends in the bumping sequence should have the same angle number but a

different bumping number. Programming a radius bend in this manner will allow for

bumping correction in the production mode.

3.i

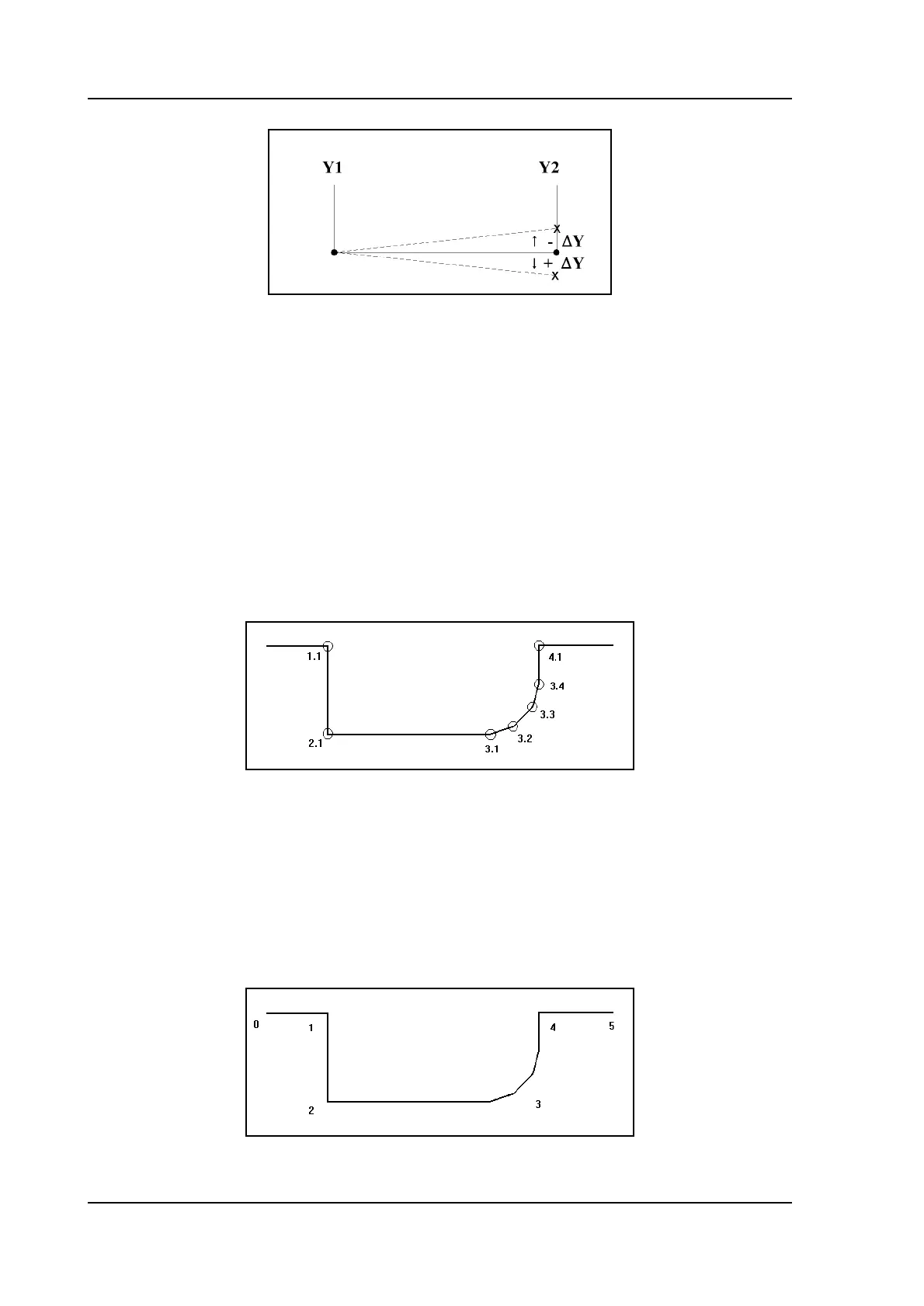

Backgauge number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .XN

A backgauge number refers to a certain spot of the product, that can be placed against the

backgauge during bending. Such a spot is either a product end or an angle. The back-

gauge numbers in the product are counted from left to right, starting with 0 (see figure

4.k). For each bend you must program here which spot must be placed against the back-

stop. If the plate must rest on the backgauge finger, add 100 to the XN value. For each

next lay-on position, add another 100 to the backgauge value (200, 300, etc.).

3.j

Loading...

Loading...