Chapter 12 Troubleshooting

1

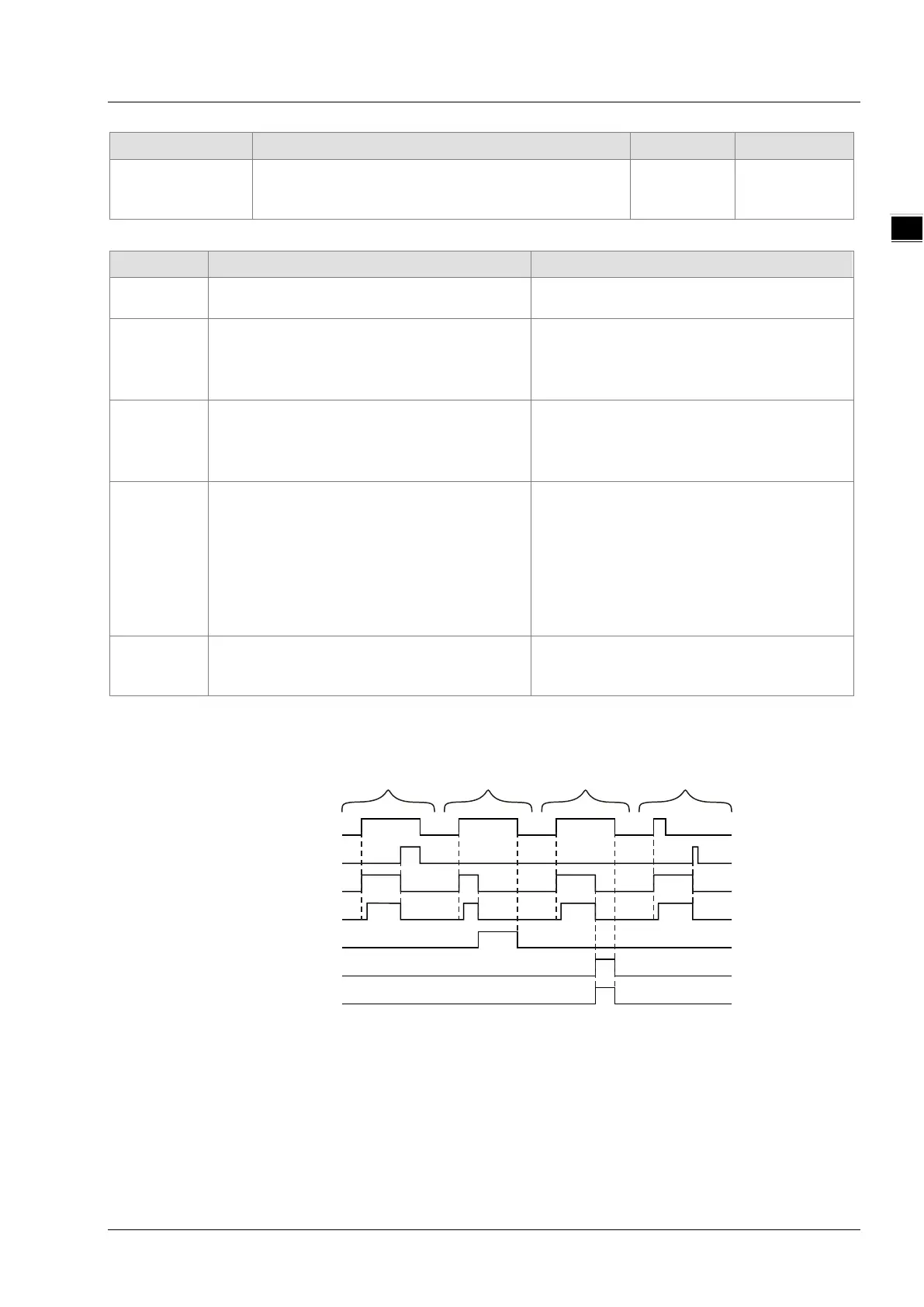

Parameter name Function Data type Valid range

RecordedPosition

The captured position after the completion of the

instruction execution. Refer to the following Function

LREAL

Output Update Timing

Name Timing for changing to TRUE Timing for changing to FALSE

Done

When the instruction execution is

completed.

When Execute changes from TRUE to

FALSE

Busy When Execute changes to TRUE.

When Done changes to TRUE.

When Error changes to TRUE.

When CommandAborted changes to

Active When Execute changes to TRUE.

When Done changes to TRUE.

When Error changes to TRUE.

When CommandAborted changes to

TRUE.

CommandA

borted

When the instruction execution is aborted

by some other motion control instruction.

When Execute changes from TRUE to

FALSE

CommandAborted is set to TRUE when

the instruction execution is aborted after

Execute changes from TRUE to FALSE

during the instruction execution. One

period later, CommandAborted changes

Error

When an error occurs in the instruction

execution or the input parameters for the

When Execute changes from TRUE to

FALSE

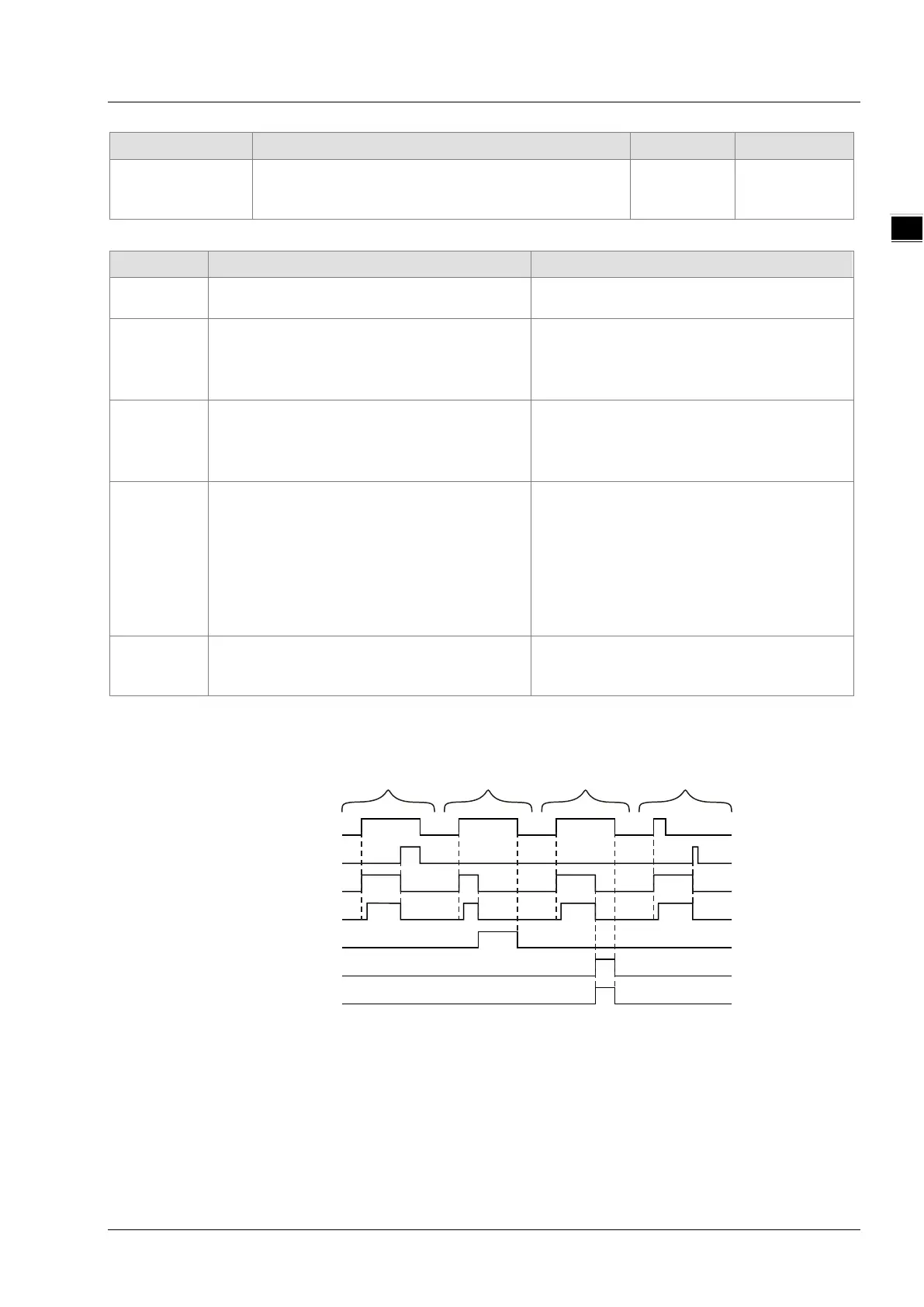

Output Update Timing Chart

Case 1: When Execute changes from FALSE to TRUE, Busy changes to TRUE and one period later,

Active changes to TRUE. When positioning is completed, Done changes to TRUE and

meanwhile Busy and Active change to FALSE.

Case 2: When Execute changes from FALSE to TRUE and the instruction is aborted by other instruction,

Commandaborted changes to TRUE and meanwhile Busy and Active change to FALSE. When

Execute changes from TRUE to FALSE, CommandAborted changes to FALSE.

Execute

Done

Busy

Active

CommandAborted

Error

Case1

Case2

Case3

Case4

Error ID

11-121

Loading...

Loading...