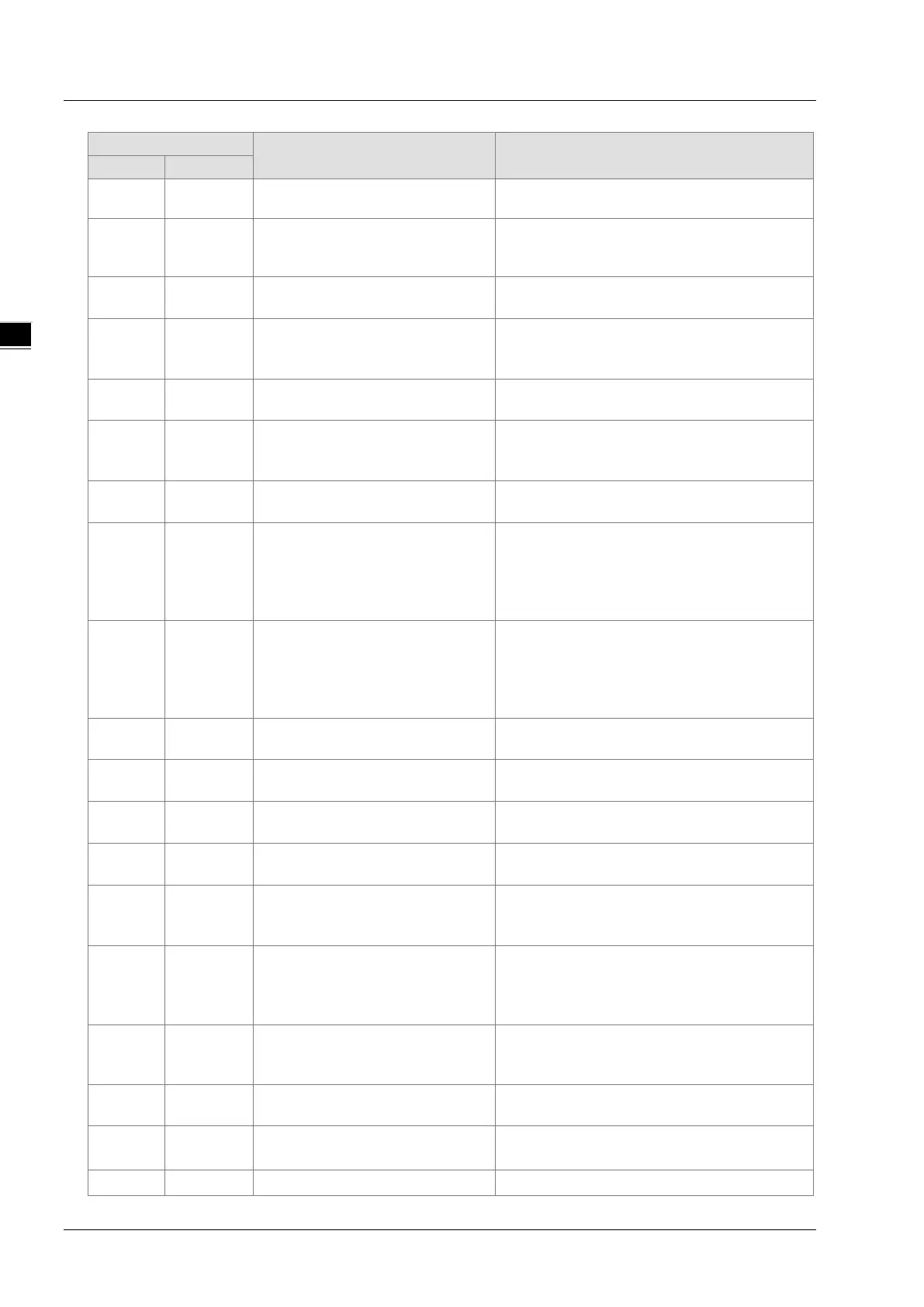

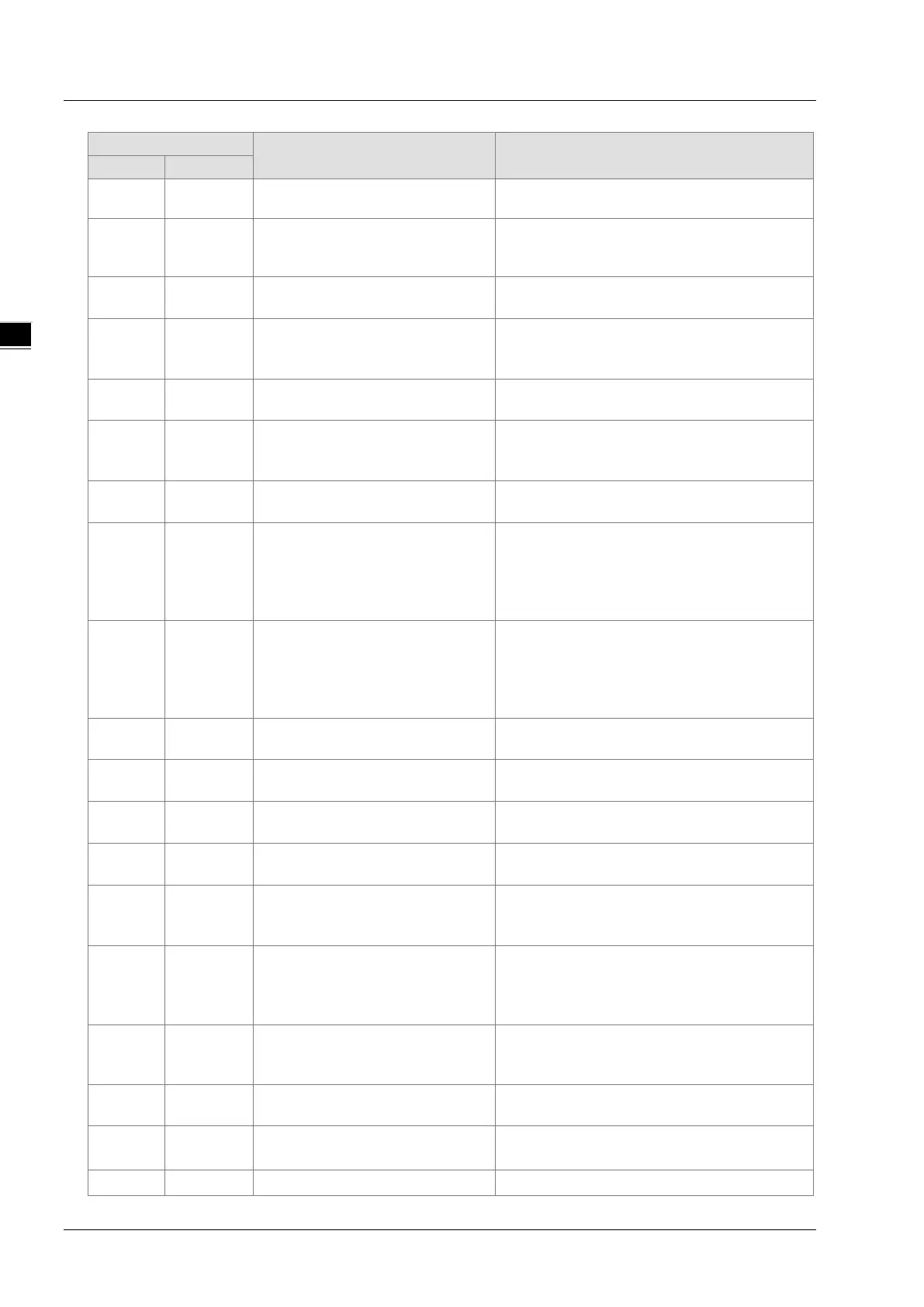

DVP15MC11T Operation Manual

Meaning How to deal with

SyncStopPos of APF_RotaryCut_Init. It should be

between 0 and the cutting length.

0x1026 4134

The settings of SyncStopPos and

SyncStartPos are incorrect.

The value of the input variable, SyncStopPos

should be less than that of SyncStartPos of the

0x1027 4135 The value of RotCutID is incorrect.

The value of the input variable, RotCutID should

0x1028 4136

The value of RotaryAxisKnifeNum is

incorrect.

The value of the input variable,

RotaryAxisKnifeNum should be in the range of

0x1029 4137 The inner state of rotary cut is illegal.

Modify the parameter values for initializing rotary

0x103A 4154 Rotary cut initializing fails.

Since APF_RotaryCut_Init has not been

executed, please execute APF_RotaryCut_Init

first and then execute APF_RotaryCut_In.

0x103B 4155

The axis is offline and the capture

function can not be performed

Execute the capture instruction after the axis is

connected normally.

0x103C 4156

The value of MasterOffset of

MC_CamIn is greater than the master

axis cam cycle range.

Modify the value of MasterOffset

the negative number and positive number of the

master axis cam cycle range. (The master axis

cam cycle range= Maximum master axis cam

cycle- Mimimum master axis cam cycle)

0x103D 4157

The value of SlaveOffset of

MC_CamIn is greater than the slave

axis cam cycle range.

Modify the value of SlaveOffset into that between

the negative number and positive number of the

slave axis cam cycle range. (The slave axis cam

cycle range= Maximum slave axis cam cycle-

Minimum slave axis cam cycle)

0x103E 4158

The Depth value of the instruction is

out of the range.

Modify the value of the input Depth in order not to

exceed the range.

0x103F 4159

The VelOverride value range of the

instruction is illegal.

Modify the value of the input VelOverride in order

not to exceed the range.

0x1040 4160 The file code is illegal.

Modify the value of the input NCFile

code value.

0x1041 4161

DMC_SetTorque is executed when

the axis is not in Standstill state.

Make sure that DMC_SetTorque is executed

when the axis is in Standstill state.

0x1042 4162 The execution of MC_Reset fails.

1. Check if the axis specified by MC_Reset exists.

2.

MC_Reset is executed after the servo alarm is

cleared.

0x1043 4163

The execution of an instruction leads

to the result that the axis position

exceeds the range set in the

Modify the instruction to make sure that the final

position does not exceed the software limit range.

0x1044 4164

The cam curve specified by

MC_CamIn is not built in the

Check if the CamTable value of MC_CamIn can

correspond to the cam curve built in the software.

0x1045 4165 Axis group ID error

Check if the value of GroupID

is within the range

of 1~8.

0x1046 4166 Mode input value error

The value of Mode for the instruction can only be

0x1047 4167

The number of the From/To

Check the value of Station and the number of the

12-10

Loading...

Loading...