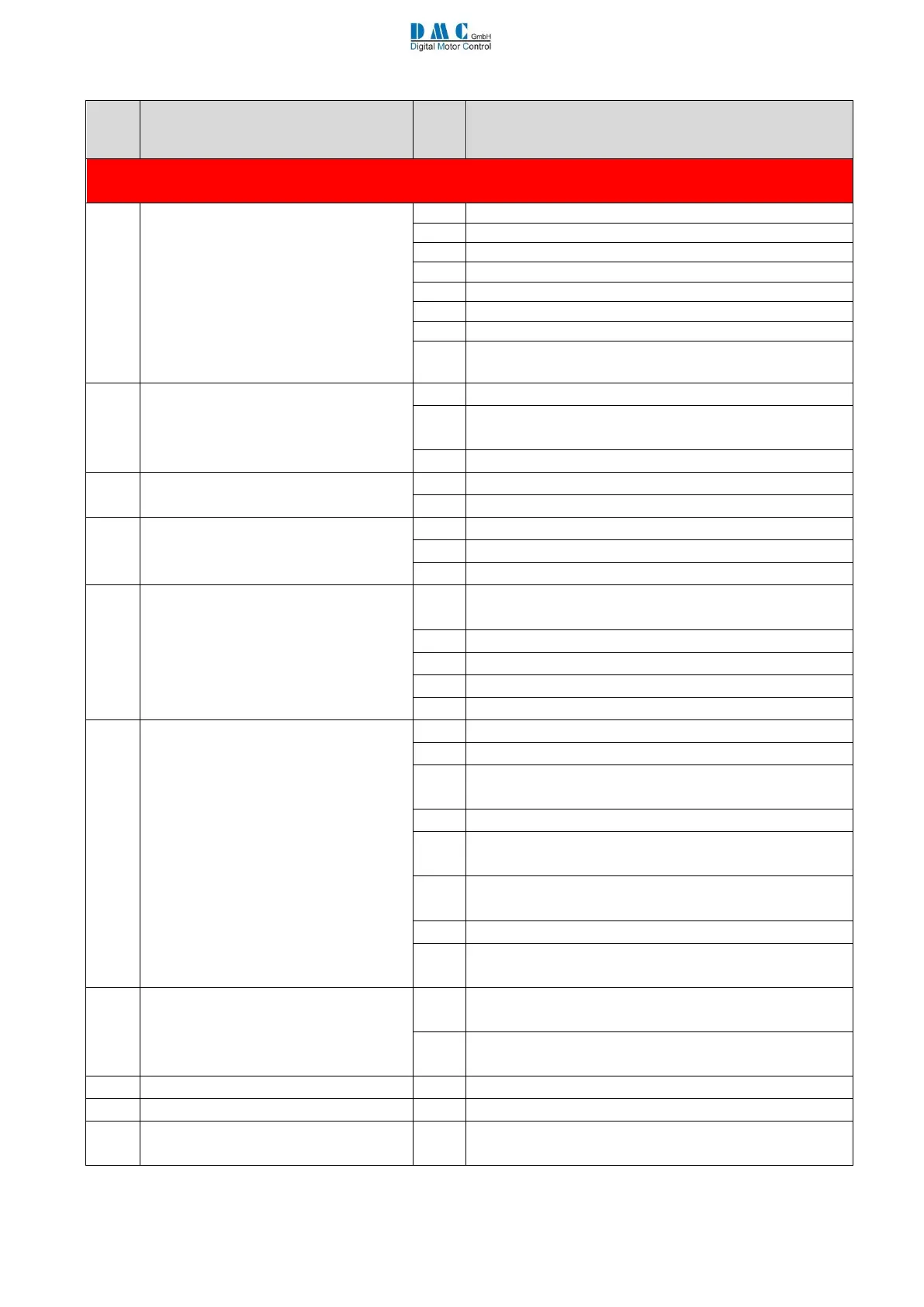

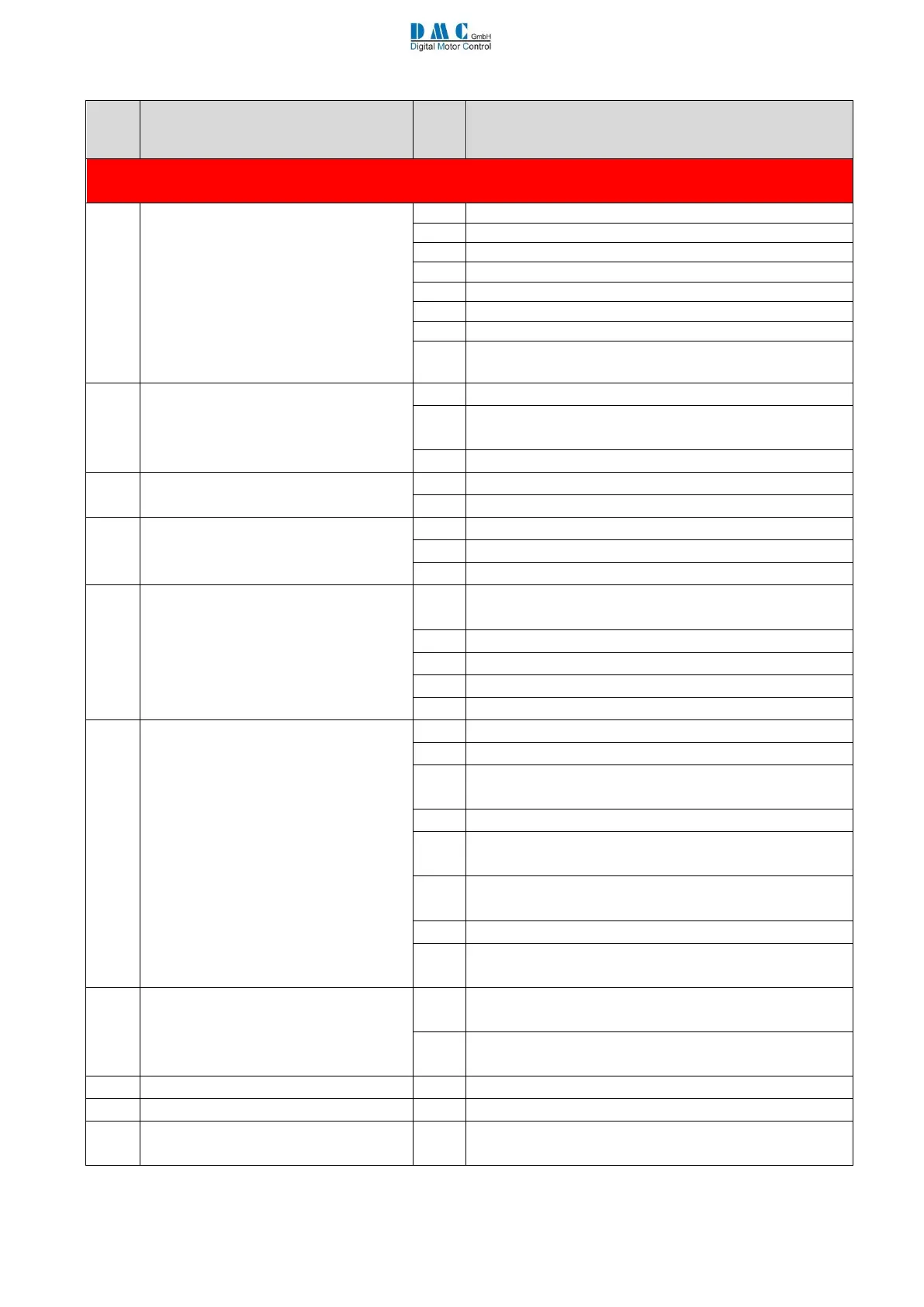

SuperSigma2 AM PMS – V1.5.6 17-1-2020 Page 92 (97) ©2019 DMC GmbH Herten Germany

… Errors continue from previous page

Hard error faults - Immediately stops pulsing and open line contactor – Reset only by a key switch recycle

Cannot finish checking the hardware fail safe

Hardware fail safe feedback is low at startup

Hardware fail safe feedback is high during toggling

Hardware fail safe feedback is low after toggling stops

Hardware fail safe encountered an unknown error

Hardware fail safe is not alive during normal run

Software watchdog caused a reset.

Recalculation is disabled now!

Line contactor fault (e.g. short circuit)

Could not discharge the capacitor bank

Capacitor bank dit not charge sufficiently to safely close

the line contactor

Line contactor opened inadvertently

Thermal shutdown fault (only for

minimum pump speed fault)

Pump low voltage shotdown

Low sided mosfets short circuit during

power up and before line contactor is

closed

Quadrature encoder sensor wire off or noise detected (AC

only)

5 V supply wire off detected

0 V supply wire off detected

Wig-wag out of safety range

Motor Temperature Sensor wire off

shared Line Contactor slave time out fault

shared Line Contactor Master fails to broadcast to slaves

shared Line Contactor requested slave is not found by

master

shared Line Contactor master time out fault

Control Via CAN HMI timeout (not receive CAN Drive

Command Message from VCU)

Control Via CAN HMI security bit error (VCU fails to toggle

security bit)

Control Via CAN HMI enable switch/wire is not connected

Can Node ID via digital inputs is detected to 0, check input

status

Motor speed is too high to commence safe pulsing (speed

is > 80 % of maximum motor speed)

Motor speed is higher than absolute maximum speed

(Check Absolute Maximum Speed)

See table "Motor sub error codes"

Motor Module initialization error

See table "Motor sub error codes"

Motor Module configuration

inconsistency

See table "Motor sub error codes"

Errors continue at next page…

Loading...

Loading...