Trouble-shooting Cerabar S/Deltabar S

152 Endress+Hauser

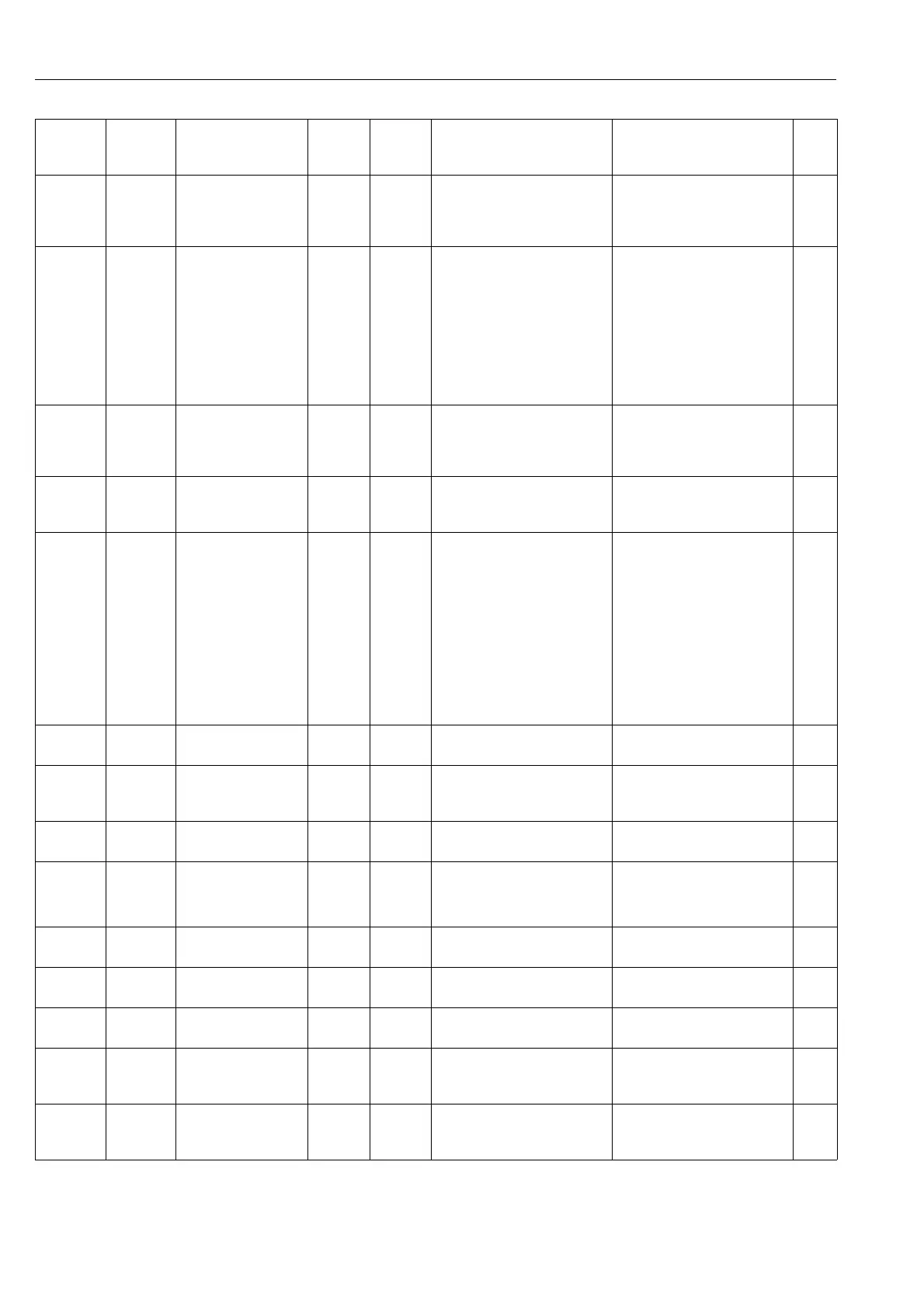

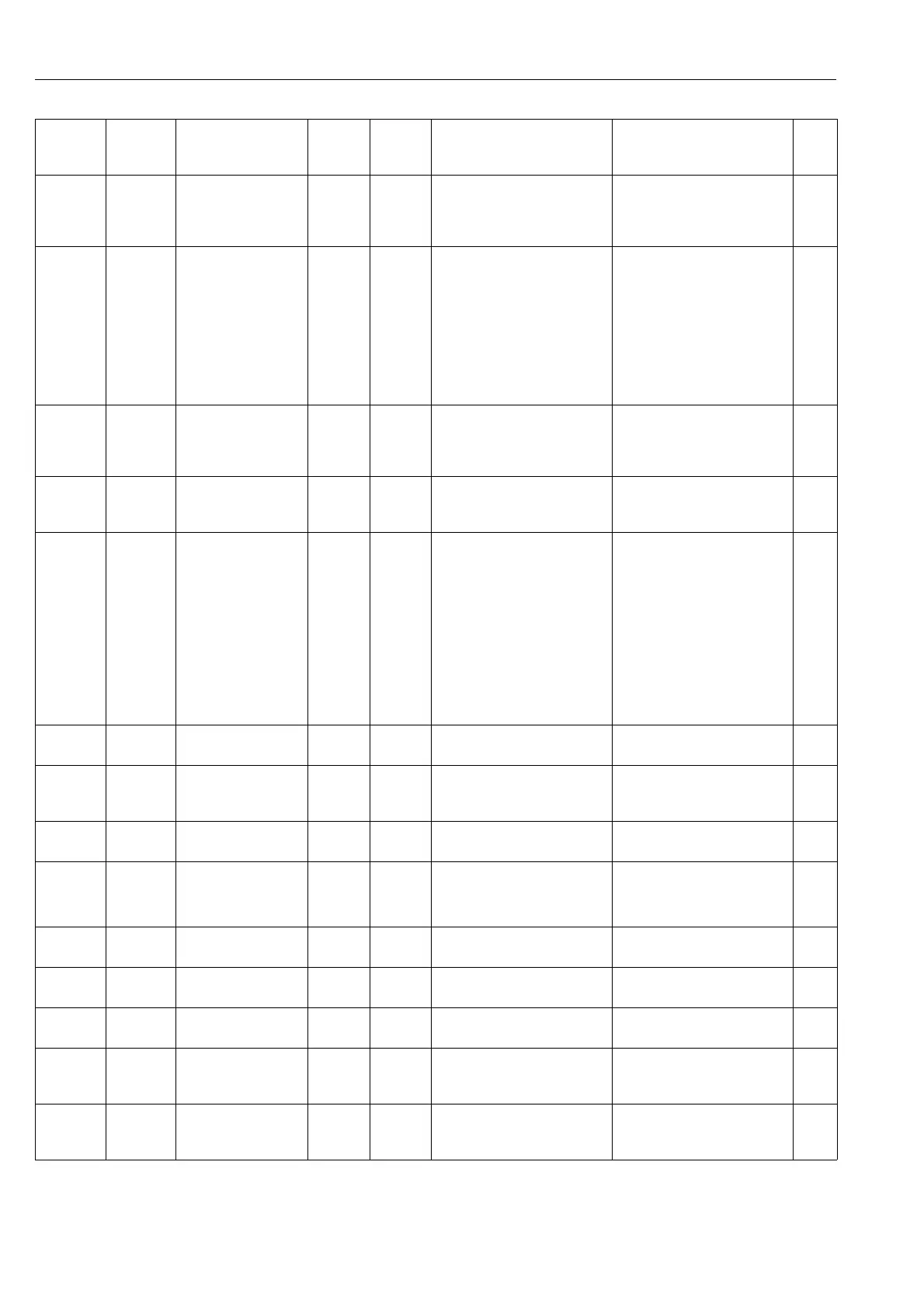

115 (E115) Error

C

C>Sensor overpressure 17 0 – Overpressure present. – Reduce pressure until message

disappears.

30

– Sensor defect. – Replace sensor.

116 (W116) Warning

C

C>Download error,

repeat download

17 0 – The file is defect. – Use another file. 37

– During the download, the data

are not correctly transmitted to

the processor, e.g. because of

open cable connections, spikes

(ripple) on the supply voltage or

electromagnetic effects.

– Check cable connection PC –

transmitter.

– Block off electromagnetic effects

or eliminate sources of

disturbance.

– Perform reset (Code 7864) and

carry out calibration again.

–Repeat download.

120 (E120) Error

C

C>Sensor low pressure 17 0 – Pressure too low. – Increase pressure until message

disappears.

31

– Sensor defect. – Replace sensor.

121 (A121) Alarm

B

B>Checksum error in

factory segment of

EEPROM

23 11 – Main electronics defect. – Replace main electronics. 5

122 (A122) Alarm

B

B>Sensor not connected 20 5 – Cable connection sensor –main

electronics disconnected.

– Check cable connection and

repair if necessary.

14

– Electromagnetic effects are

greater than specifications in the

technical data.

→ See Technical Information

TI382P (Deltabar S) or TI383P

(Cerabar S).

– Block off electromagnetic effects

or eliminate source of

disturbance.

– Main electronics defect. – Replace main electronics.

– Sensor defect. – Replace sensor.

130 (A130) Alarm

B

B>EEPROM is defect. 23 11 – Main electronics defect. – Replace main electronics. 10

131 (A131) Alarm

B

B>Checksum error in

EEPROM: min/max

segment

23 11 – Main electronics defect. – Replace main electronics. 9

132 (A132) Alarm

B

B>Checksum error in

totalizer EEPROM

23 11 – Main electronics defect. – Replace main electronics. 7

133 (A133) Alarm

B

B>Checksum error in

History EEPROM

23 11 – An error occurred when

writing.

– Perform reset (Code 7864) and

carry out calibration again.

8

– Main electronics defect. – Replace electronics.

134 (W134) Warning

C

C>EEPROM lifetime

WARNING

17 0 – Writing too often to EEPROM. – Reduce write accessing to

EEPROM.

55

135 (A135) Alarm

B

B>Checksum error in

EEPROM FF segment

23 11 – Main electronics defect. – Replace main electronics. 10

602 (W602) Warning

C

C>Linearisation curve

not monoton

17 0 – The linearisation table is not

monotonic increasing.

– Add to linearisation table or

perform linearisation again.

57

604 (W604) Warning

C

C>Linearisation table

not valid. At least 2

points

23 11 – The linearisation table consists

of less than 2 points.

– Add to linearisation table. If

necessary, perform linearisation

again.

58

613 (W613) Warning

I

I>Simulation is active 17 3 – Simulation is switched on, i.e.

the device is not measuring at

present.

– Switch off simulation. 60

Code Error

type/

NA 64

Message/description XD_

ERROR

Value

BLOCK_

ERROR

Value

Cause Measure Prio-

rity

Loading...

Loading...