Cerabar S/Deltabar S Flow measurement (ToF Tool)

Endress+Hauser 89

9 Flow measurement (ToF Tool)

9.1 Calibration

Example:

In this example, a volume flow should be measured in m

3

/h.

!

Note!

• The "Flow measurement" measuring mode is only available for the Deltabar S differential pressure

transmitter.

• See also Operating Instructions BA301P Deltabar S, Section 6.5 "Flow measurement".

• For a description of the parameters mentioned, see

– Page 98, ToF Tool, table 4: POSITION ADJUSTMENT

– Page 125 ff, ToF Tool, table 10: BASIC SETUP

• For a description of further parameters, see

– Page 130, ToF Tool, table 13: EXTENDED SETUP

– Page 144, ToF Tool, table 23: PROCESS VALUES.

Description

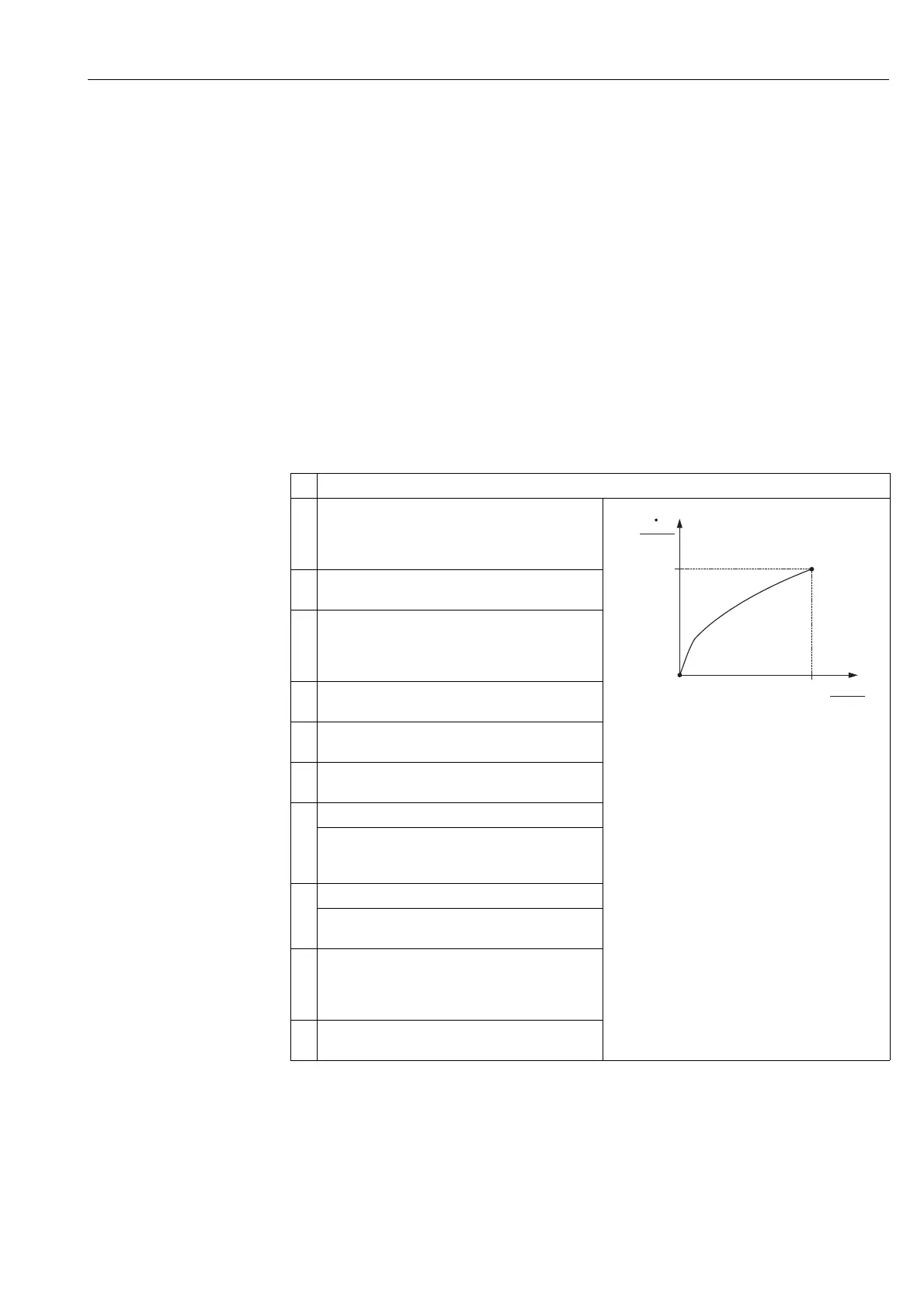

1 Before configuring the device for your application, the

pressure piping must be cleaned and the device filled

with fluid. See Operating Instructions BA301P, Section

6.5.1.

P01-xMD7xxx-05-xx-xx-xx-010

Fig. 17: Flow measurement calibration

1 See table, step 7.

2 See table, step 8.

2 Carry out position adjustment if necessary. See Page 98,

ToF Tool, table 4: POSITION ADJUSTMENT.

3 If necessary, select the "Flow" measuring mode via the

MEASURING MODE parameter.

Menu path: OPERATING MENU → SETTINGS →

BASIC SETUP → MEASURING MODE

4 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

5 Select the "Volume p. cond." option by means of the

FLOW-MEAS. TYPE parameter.

6 Select a flow unit via the UNIT FLOW parameter, here

m

3

/h for example.

7Select MAX. FLOW parameter.

Enter the maximum flow value of the primary device,

here 6000 m

3

/h for example. See also layout sheet of

primary device.

8 Select MAX PRESS. FLOW parameter.

Enter the maximum pressure, here 400 mbar for

example. See also layout sheet of primary device.

9 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

10 Result:

The device is configured for flow measurement.

➀

p

[mbar]

➁

6000

0

0 400

[m /h]

3

V

Loading...

Loading...