Pressure measurement (ToF Tool) Cerabar S/Deltabar S

74 Endress+Hauser

7 Pressure measurement (ToF Tool)

!

Note!

• The device is configured for the pressure measuring mode as standard. The measuring range and

the unit in which the measured value is transmitted, as well as the digital output value of the

Analog Input Block OUT, correspond to the data on the nameplate.

• See also Operating Instructions BA301P Deltabar S, Section 6.7 "Differential pressure

measurement" or Operating Instructions BA302P Cerabar S, Section 6.5 "Pressure

measurement".

• For a description of the parameters mentioned, see

– Page 98, ToF Tool, table 4: POSITION ADJUSTMENT

– Page 99, ToF Tool, table 5: BASIC SETUP.

• For a description of further relevant parameters, see

– Page 129, ToF Tool, table 11: EXTENDED SETUP

– Page 142, ToF Tool, table 21: PROCESS VALUES.

!

Note!

• You can also specify a customer-specific unit. See parameter description for PRESS. ENG. UNIT

(→ Page 100).

Description

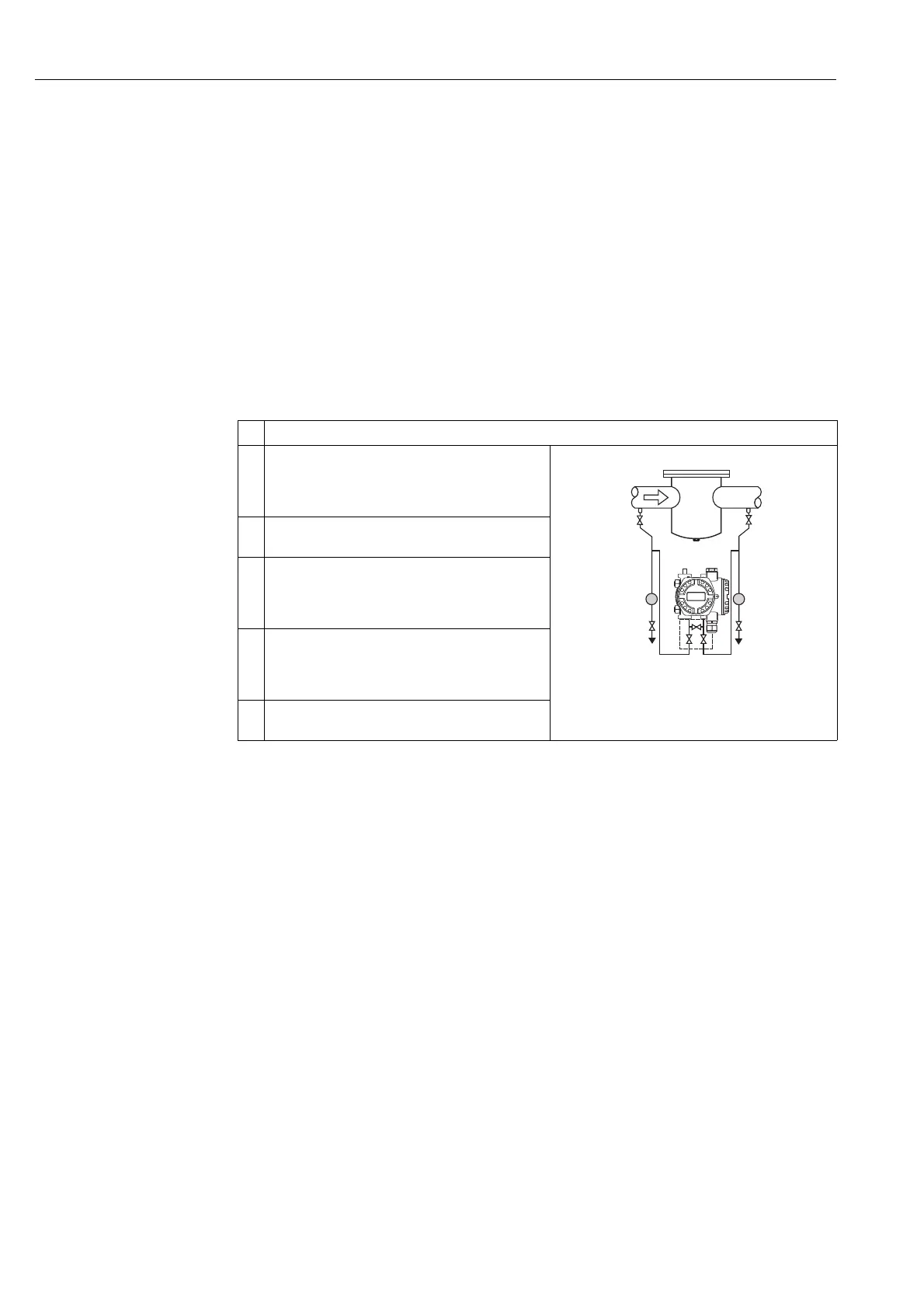

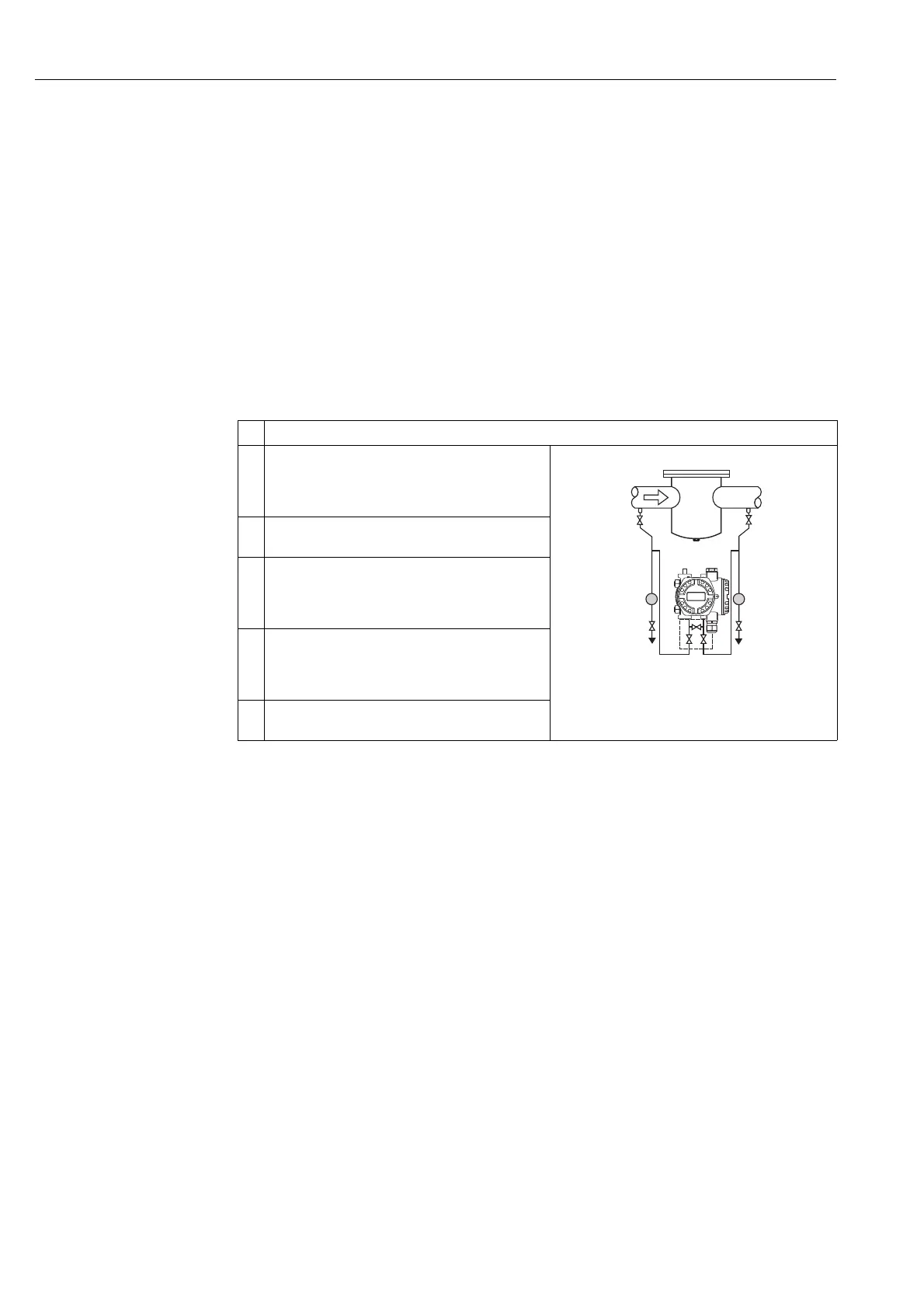

1 Deltabar S: before configuring the device for your

application, the pressure piping must be cleaned and the

device filled with fluid. See Operating Instructions

BA301P, Section 6.7.

P01-PMD75xxx-19-xx-xx-xx-000

2 Carry out position adjustment if necessary. See Page 98,

ToF Tool, table 4: POSITION ADJUSTMENT.

3 If necessary, select the "Pressure" measuring mode via

the MEASURING MODE parameter.

Menu path: OPERATING MENU → SETTINGS →

BASIC SETUP → MEASURING MODE

4 If necessary, use the Analog Input Block to configure the

CHANNEL parameter (→ Page 67), L_TYPE parameter

(→ Page 69), XD_SCALE parameter (→ Page 73) and

OUT_SCALE parameter (→ Page 71).

5Result:

The device is ready for pressure measurement.

+

–

Loading...

Loading...