Liquiline System CA80SI Diagnostics and troubleshooting

Endress+Hauser 119

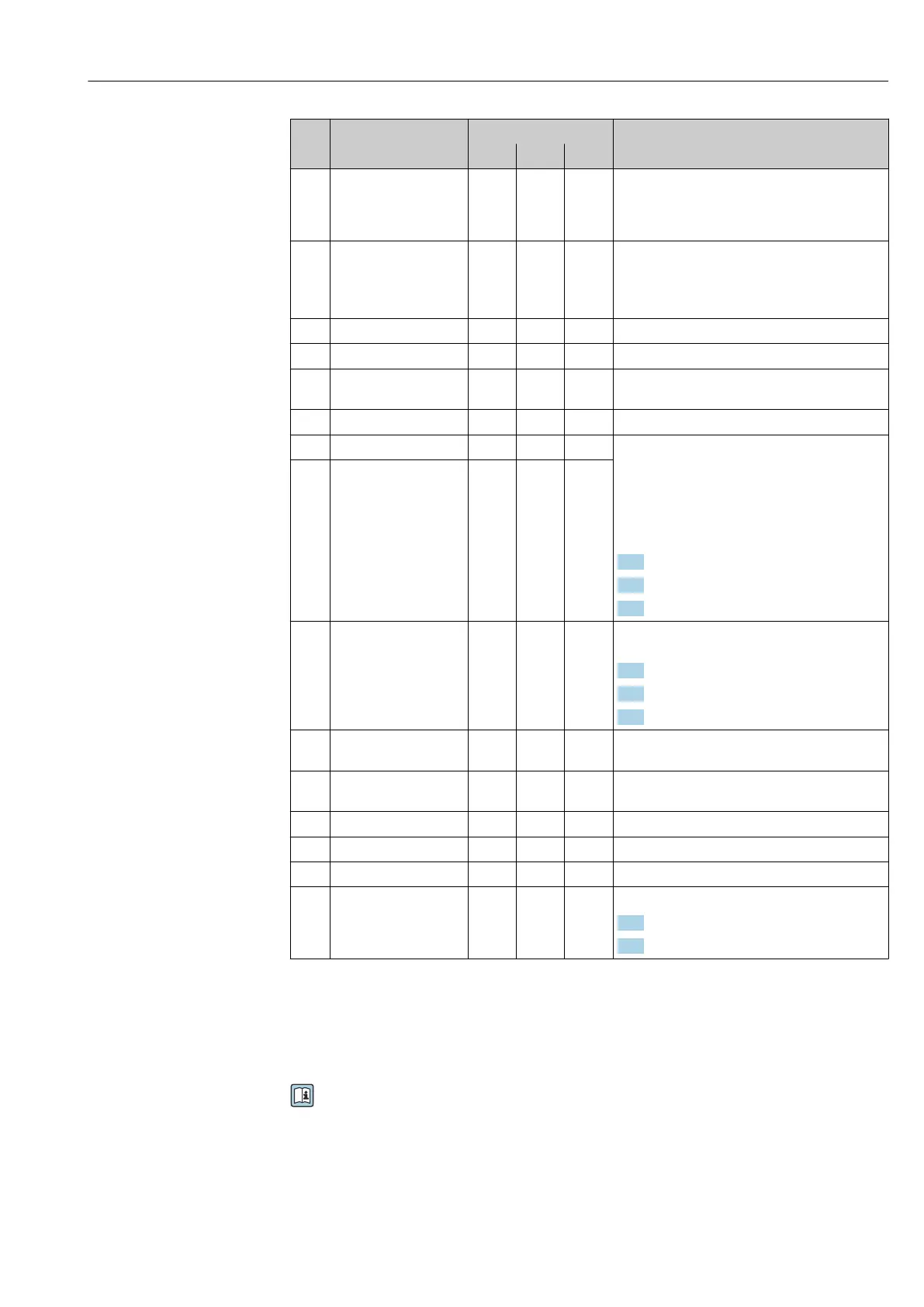

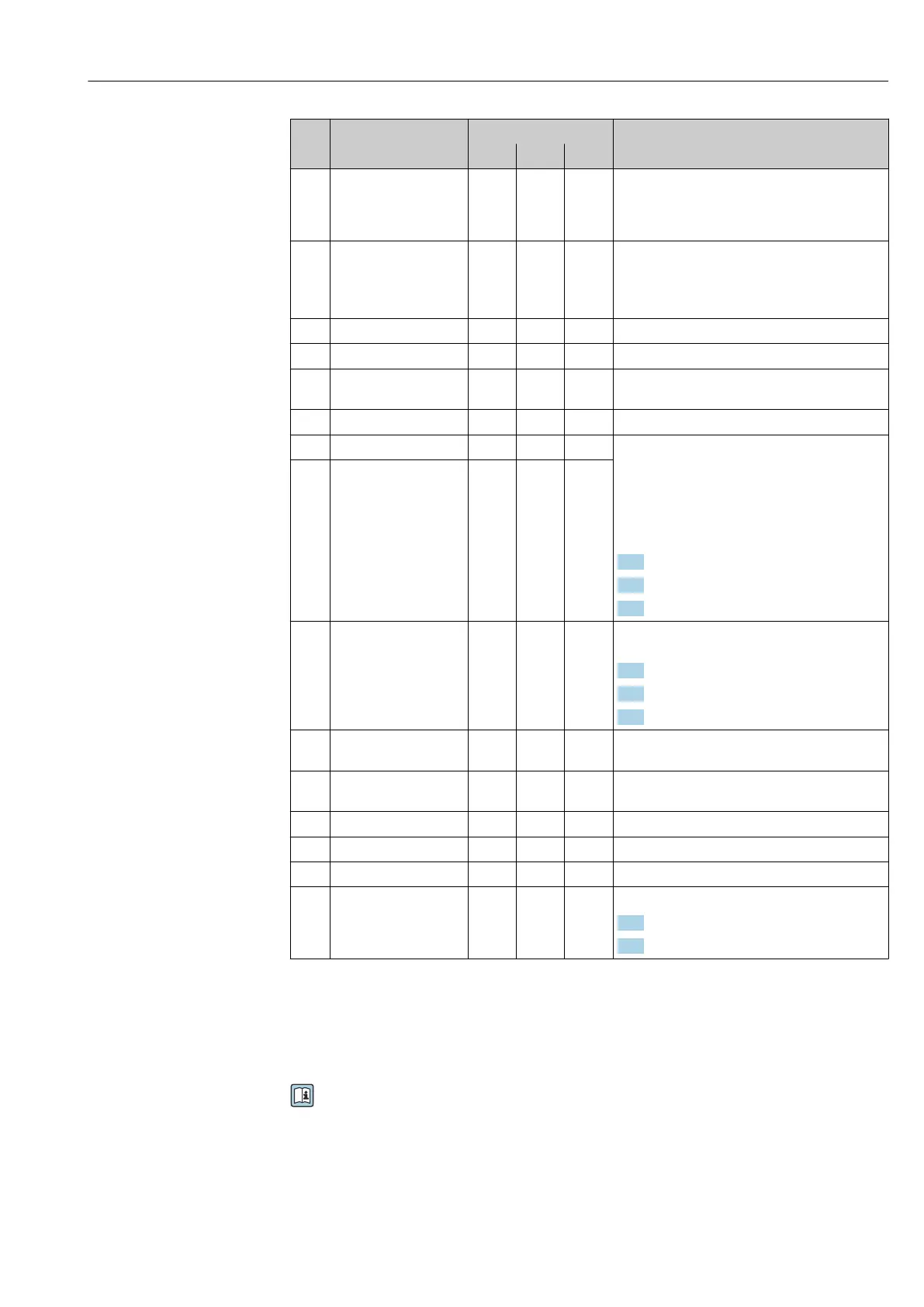

No. Message Factory settings Tests or remedial action

S

1)

D

2)

F

3)

970 Curr. input overload S On On Current input overloaded

The current input is switched off from 23 mA due

to overload and reactivated automatically when a

normal load is present.

971 Current Input low S On On Current input too low

At 4 to 20 mA, the input current is less than the

lower failure current.

‣

Check the input for short-circuiting

972 Curr. input > 20 mA S On On Current output range exceeded

973 Current Input < 4 mA S On On Current output range undershot

974 Diagnostics confirm. C Off Off User has acknowledged the message displayed in

the measuring menu.

975 Device restart C Off Off Device reset

976 PFM value high S On Off Pulse frequency modulation: output signal

exceeded/undershot. Measured value outside the

specified range.

• Sensor in air

• Air pockets in assembly

• Incorrect flow to sensor

• Sensor fouled

1. Clean sensor

2. Check plausibility

3. Adjust the PFM configuration

977 PFM value low S On Off

978 ChemoClean Failsafe S On On No feedback signal detected within the configured

period.

1. Check the application

2. Check the wiring

3. Extend the duration

990 Deviation limit F On On Redundancy: limit value of percentage deviation

exceeded

991 CO2 conc. range F On On CO

2

concentration (degassed conductivity) outside

the measuring range

992 pH calculation range F On On pH calculation outside the measuring range

993 rH calculation range F On On rH calculation outside the measuring range

994 Difference conduct. F On On Dual conductivity outside the measuring range

995 Mathematical error S On On Incorrect calculation result

1. Check the mathematical functions.

2. Check the input variables.

1) Status signal

2) Diagnostic message

3) Error current

12.6.2 Sensor-specific diagnostic messages

Operating Instructions "Memosens", BA01245C

12.7 Pending diagnostic messages

The Diagnostics menu contains all the information on the device status. Furthermore,

various service functions are available.

Loading...

Loading...