Enertech Global

EAV - EME/EMD Rev. A Models

Installaon and Operaons Manual

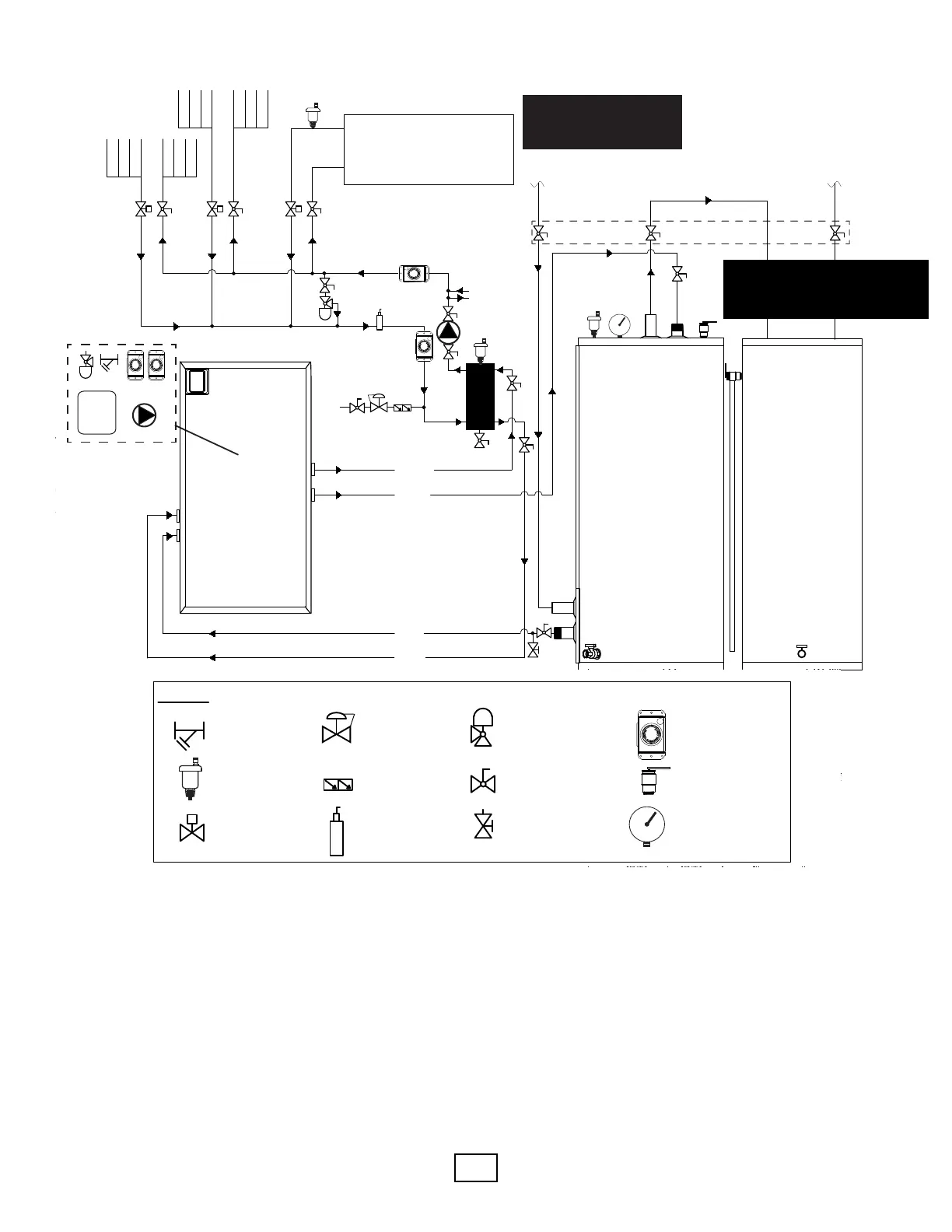

WV Installation: Heat & Cool-with Hot Water

OPTIONAL

NON-PRESSURIZED

FLOW CENTER

TO

LOOP

FIELD

FROM

LOOP

FIELD

SOURCE IN

SOURCE OUT

P/TP/T

P/T

FLUSH

VALVE

Type XXXX XX-XX XXX

XXXV ~

XX/XXHz

GFXXX

EuP Ready

I

1/1

(A)

P

1

(W)

X.XX

X.XX

XX

XX

Max.

Min.

P/N:XXXXXXX

PC:XXXXXX

IP XX

TF XX

Max.X.XMPa

A

High Efficiency

XX

EEI<0.23

NOTE 5

HYDRAULIC

SEPARATOR

RADIANT

FLOOR

HEATING

ZONE 2

RADIANT

FLOOR

HEATING

ZONE 3

HYDRONIC

AIR HANDLER

ZONE 1

DHW OUT

ΔP

LOAD OUT

NOTE 4

NOTE 7

NOTE 6

NOTE 6

NOTE 6

NOTE 6

TURBOMAX

WATER HEATER

DOMESTIC

HOT

WATER

DOMESTIC

COLD

WATER

HOT

HOTCOLD

COLD

LOAD

IN

LOAD

OUT

BACKUP

ELECTRIC OR GAS

WATER HEATER

AUTOMATIC

AIR VENT

3-WAY FLUSH

VALVE

PRESSURE

RELIEF VALVE

PRESSURE

GAUGE

ΔP

LEGEND

WYE STRAINER

ACTUATED

ZONE VALVE

PRESSURE

REDUCING VLV

BACK-FLOW

PREVENTER

AIR ELIMINATOR

DIF. PRESSURE

BYPASS VALVE

ISOLATION BALL

VALVE

BOILER DRAIN

ALWAYS CHECK LOCAL CODE REQUIREMENTS TO ENSURE THAT THE INSTALLATION MEETS CURRENT

CLOSELY SPACED TEES FOR CONNECTION TO BACKUP BOILER. SEE FIGURE 12D FOR DETAILS.

NOTES:

1. INSTALLATION DIAGRAM SHOWN ABOVE IS AN EXAMPLE OF A TYPICAL (RECOMMENDED) INSTALL. ADDITIONAL

ZONES ARE ALLOWED, AS WELL AS ALTERNATE PIPING LAYOUTS.

2. UNIT CONFIGURATION/MODEL INCLUDES INDIRECT DHW TANK.

3. A HOSE KIT HAS BEEN PROVIDED WITH THE UNIT AND SHOULD BE INSTALLED AT THE OUTDOOR UNIT.

AN AUTOMATIC AIR VENT AND AIR SEPARATOR ARE SUPPLIED AS FIELD INSTALLED COMPONENTS.

4.

5.

6.

9.

BYPASS VALVE (REQUIRED) IS USED TO AVOID DEAD-HEADING PUMP IF ALL ZONE VALVES ARE CLOSED.

FIELD PROVIDED.

REGULATORY STANDARDS.

ALL PIPING MUST BE “HOME RUN” STYLE. ALL RADIANT MANIFOLDS AND AIR HANDLER UNIT ZONE VALVES

SHOULD BE LOCATED IN THE MECHANICAL TO FACILITATE FLUSHING/PURGING OF AIR FROM SYSTEM.

7.

AT HIGHEST POINT IN SYSTEM.

8.

See Figure 11.

NOTE 6 NOTE 6 NOTE 6

BUFFER TANK REQUIRED IF ANY

FAN COIL/AIR HANDLER ZONES

ARE SMALLER THAN 2 TONS

(SEE FIGURE 12D).

⚠ CAUTION ⚠

MAKE-UP

WATER

SYSTEM

PUMP

NOTE 8

NOTE 6

ΔP

Expan.

Tank

FACTORY INSTALLED

INTERNAL TO UNIT

INDOOR UNIT

LOAD IN

DHW IN

NOTE 6

NOTICE:

BACKUP WATER

HEATER STRONGLY

RECOMMENDED FOR

RESIDENTIAL

APPLICATIONS

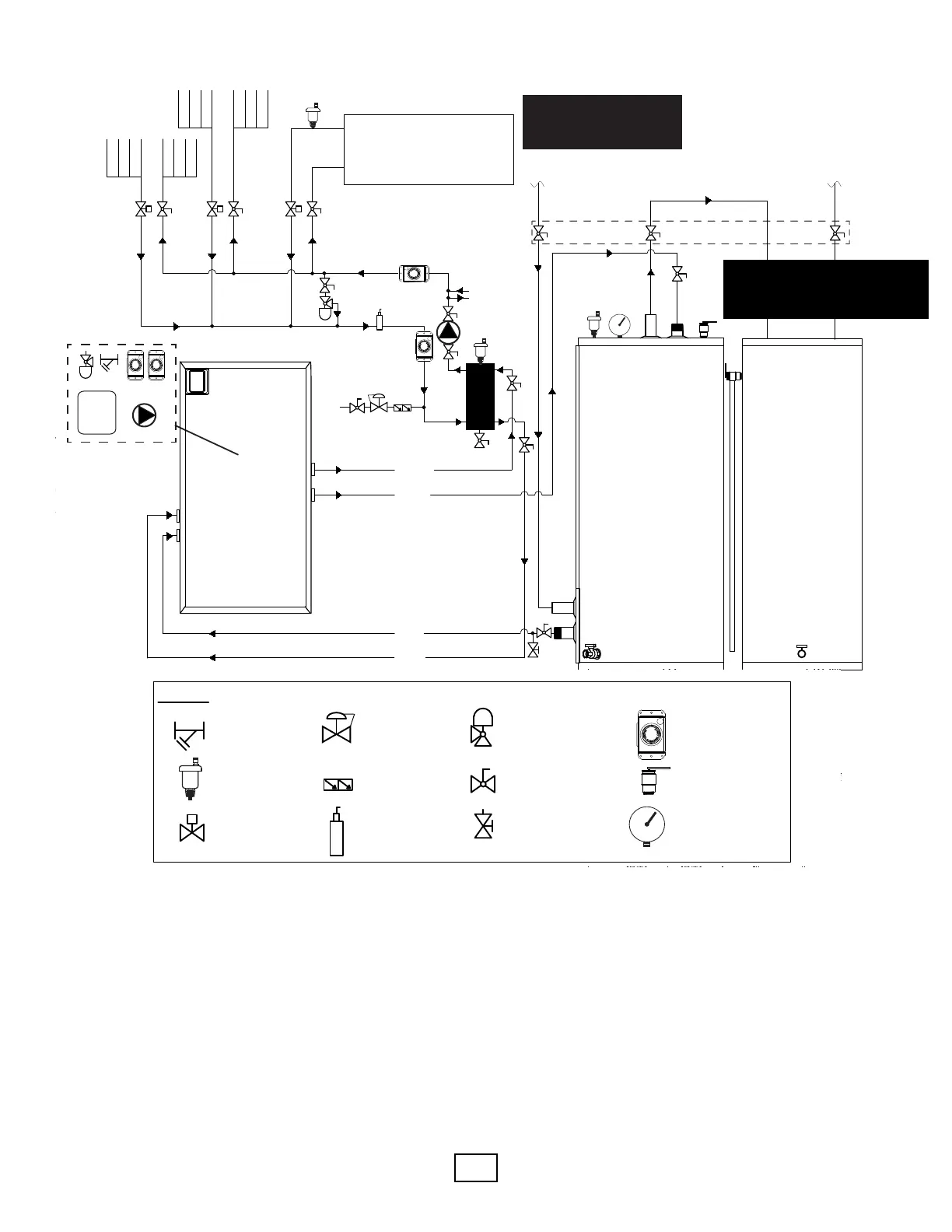

WV Installation: Heat & Cool-with Hot Water

OPTIONAL

NON-PRESSURIZED

FLOW CENTER

TO

LOOP

FIELD

FROM

LOOP

FIELD

SOURCE IN

SOURCE OUT

P/TP/T

P/T

SOURCE IN

SOURCE OUT

TO

LOOP

FIELD

FROM

LOOP

FIELD

FLUSH

VALVE

Type XXXX XX-XX XXX

XXXV ~

XX/XXHz

GFXXX

EuP Ready

I

1/1

(A)

P

1

(W)

X.XX

X.XX

XX

XX

Max.

Min.

P/N:XXXXXXX

PC:XXXXXX

IP XX

TF XX

Max.X.XMPa

A

High Efficiency

XX

EEI<0.23

NOTE 5

HYDRAULIC

SEPARATOR

RADIANT

FLOOR

HEATING

ZONE 2

RADIANT

FLOOR

HEATING

ZONE 3

HYDRONIC

AIR HANDLER

ZONE 1

DHW OUT

ΔP

LOAD OUT

NOTE 4

NOTE 7

NOTE 6

NOTE 6

NOTE 6

NOTE 6

TURBOMAX

WATER HEATER

DOMESTIC

HOT

WATER

DOMESTIC

COLD

WATER

HOT

HOTCOLD

COLD

LOAD

IN

LOAD

OUT

BACKUP

ELECTRIC OR GAS

WATER HEATER

AUTOMATIC

AIR VENT

3-WAY FLUSH

VALVE

PRESSURE

RELIEF VALVE

PRESSURE

GAUGE

ΔP

LEGEND

WYE STRAINER

ACTUATED

ZONE VALVE

PRESSURE

REDUCING VLV

BACK-FLOW

PREVENTER

AIR ELIMINATOR

DIF. PRESSURE

BYPASS VALVE

ISOLATION BALL

VALVE

BOILER DRAIN

ALWAYS CHECK LOCAL CODE REQUIREMENTS TO ENSURE THAT THE INSTALLATION MEETS CURRENT

CLOSELY SPACED TEES FOR CONNECTION TO BACKUP BOILER. SEE FIGURE 12D FOR DETAILS.

NOTES:

1. INSTALLATION DIAGRAM SHOWN ABOVE IS AN EXAMPLE OF A TYPICAL (RECOMMENDED) INSTALL. ADDITIONAL

ZONES ARE ALLOWED, AS WELL AS ALTERNATE PIPING LAYOUTS.

2. UNIT CONFIGURATION/MODEL INCLUDES INDIRECT DHW TANK.

3. A HOSE KIT HAS BEEN PROVIDED WITH THE UNIT AND SHOULD BE INSTALLED AT THE OUTDOOR UNIT.

AN AUTOMATIC AIR VENT AND AIR SEPARATOR ARE SUPPLIED AS FIELD INSTALLED COMPONENTS.

4.

5.

6.

9.

BYPASS VALVE (REQUIRED) IS USED TO AVOID DEAD-HEADING PUMP IF ALL ZONE VALVES ARE CLOSED.

FIELD PROVIDED.

REGULATORY STANDARDS.

ALL PIPING MUST BE “HOME RUN” STYLE. ALL RADIANT MANIFOLDS AND AIR HANDLER UNIT ZONE VALVES

SHOULD BE LOCATED IN THE MECHANICAL TO FACILITATE FLUSHING/PURGING OF AIR FROM SYSTEM.

7.

AT HIGHEST POINT IN SYSTEM.

8.

See Figure 11.

NOTE 6 NOTE 6 NOTE 6

BUFFER TANK REQUIRED IF ANY

FAN COIL/AIR HANDLER ZONES

ARE SMALLER THAN 2 TONS

(SEE FIGURE 12D).

⚠ CAUTION ⚠

MAKE-UP

WATER

SYSTEM

PUMP

NOTE 8

NOTE 6

ΔP

Expan.

Tank

FACTORY INSTALLED

INTERNAL TO UNIT

INDOOR UNIT

LOAD IN

DHW IN

NOTE 6

NOTICE:

BACKUP WATER

HEATER STRONGLY

RECOMMENDED FOR

RESIDENTIAL

APPLICATIONS

1. Installaon diagram shown above is n example of a typical (recommended) install. Addional zones are allowed, as well as

alternave piping layouts.

2. Unit conguraons/model includes indirect DHW tank.

3. A ex tubing kit has been provided with the unit and should be installed at the outdoor unit. An automac air vent and air

separator are supplied as eld installed components.

4. All piping must be “Home Run” style. All radiant manifolds and air handler unit zones valves should be located in the mechanical

room to facilitate ushing/purging of air from system.

5. Bypass valve (required) is used to avoid dead-heading pump if all zone valves are closed. See for details.

6. Field Provided

7. At highest point in the system.

8. Closely spaced tees for connecon to backup boiler. See for details

9. Always check local code requirements to ensure that the installaon meets current regulatory standards.

BACKUP ELECTRIC OR

GAS WATER HEATER

(STRONGLY

RECOMMENDED

FOR RESIDENTIAL

APPLICATIONS)

TURBOMAX

WATER HEATER

⚠⚠

Loading...

Loading...