Enertech Global

EAV - EME/EMD Rev. A Models

Installaon and Operaons Manual

It is important to follow best pracces for mounng the system

pump to provide long life, serviceability, and the ability to purge

air out of the system. Following are two important ps for

ensuring a good installaon:

• Pumping up is the best way to mount

the pump. If there is air in the system, it will have the best

chance of the air geng though the pump, to the air

separator, and out of the system. If the pump air locks, turn

the pump o and the air will go up out of the impeller and

will be replaced with water. Restart the pump and it will

start pumping. The air will ow to the air separator. In most

cases the air will go through the pump. Pumping

horizontally will work as long as there are small pockets of

air in the system. They will keep moving around the system

with the water to the air separator. If there are big pockets

of air in the system, this will create problems for horizontal

mounng. The pump will cavitate, lose water ow,

overheat, and fail. If the pump does get air locked, there will

need to be a purge port so that the air can be ushed out of

the pump and system. Pumping down is the poorest way to

mount a pump. If there is air in the system it will get

trapped in the pump, causing it to cavitate, loose water

ow, overheat, and fail. The air creates resistance in the

down owing water because the air wants to ow up. If the

pumps loses ow or stops, the air comes back up the pipe

into the impeller, amplifying the problem. If the pump gets

air locked, there will need to be a purge port so that the air

can be ushed out of the pump and system.

• The pump is a wet rotor pump. The

motor sha must be horizontal to keep the bearings

properly lubricated. Do not put the pump on its back or

poinng down (vercal sha) because this orientaon can

cause premature pump failure. In most cases, the direcon

of the electrical box is important to keep any condensaon

out of the windings. Some pumps have a yellow scker that

is on the head of the pump, indicang the proper direcon.

Piping diagrams in are schemacs. Not all

components are shown, such as union ngs, piping adapters/

reducers, and other components. Schemacs are designed for

illustrang the arrangement/funcon of the components.

Always use best pracces when considering the locaon of the

various components. For example, the expansion tank must

always be on the sucon side of the pump; check valves (if

applicable) must always be on discharge of the pump.

are schemac drawings. Successful design of

the system must also include pipe diameter and layout. The

following guidelines should be considered for all hydronic

designs:

• Purging air from the system is

one of biggest challenges for hydronic systems.

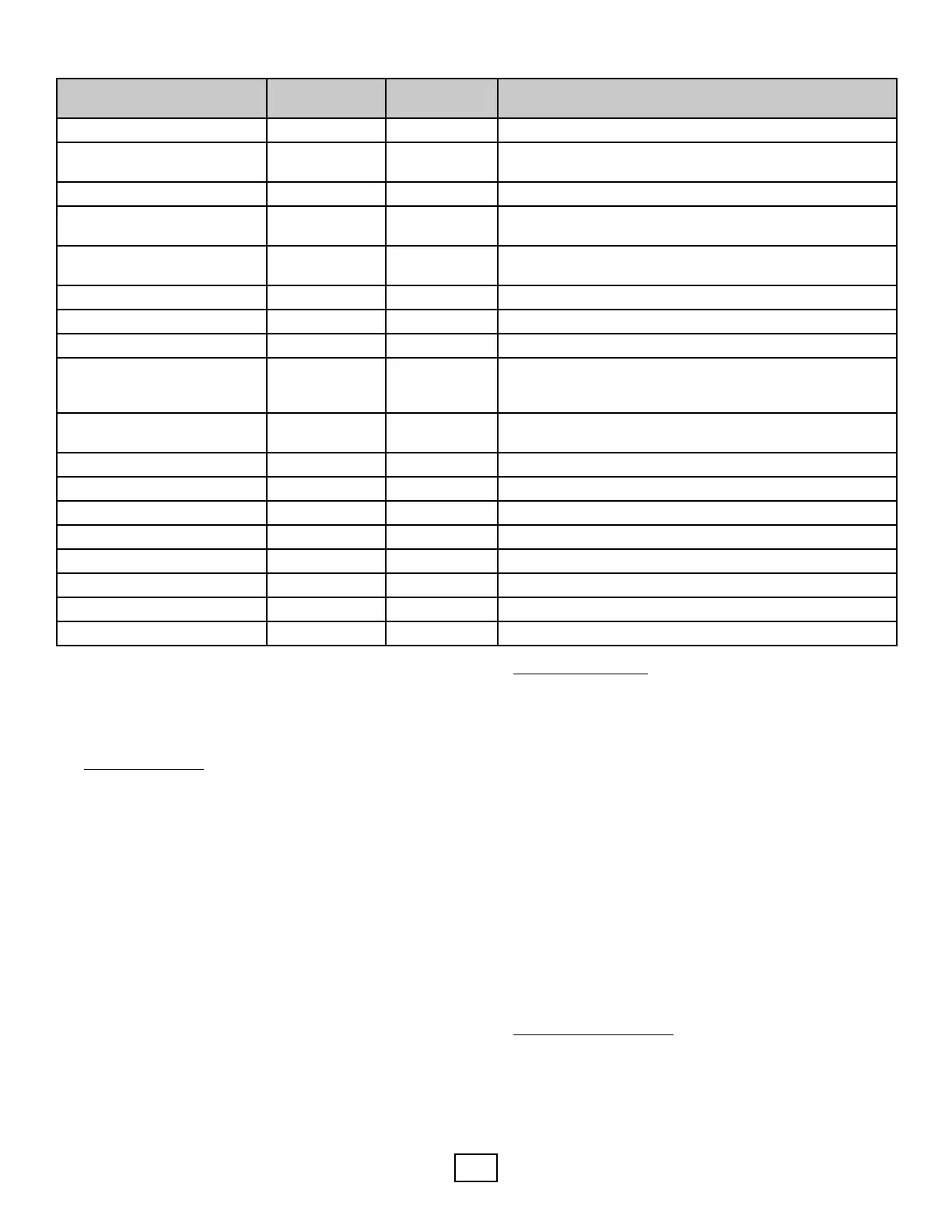

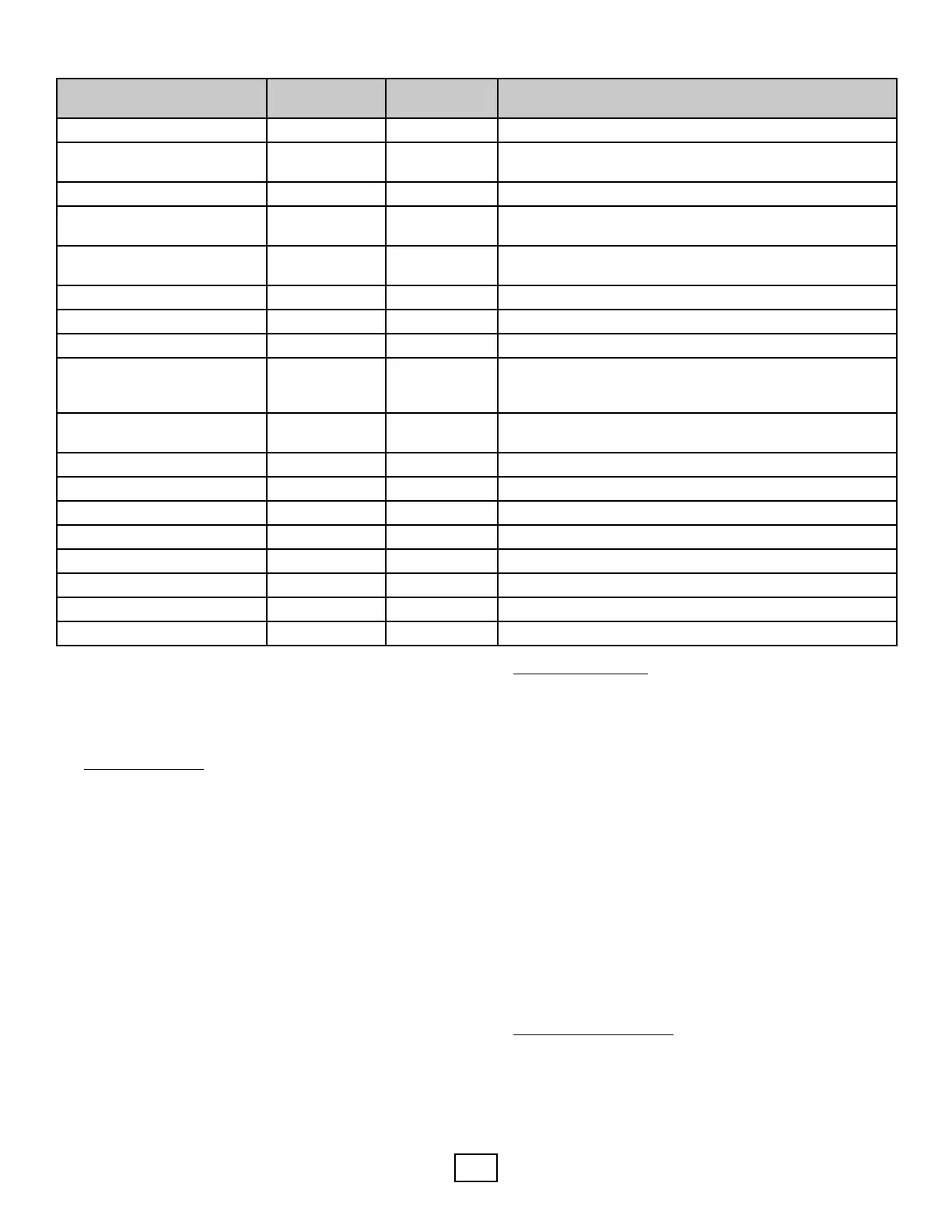

Automac Air Vent, Taco Y 03P017-01BN Install at highest point in system

Boiler Trim Kit Y See Notes

Expansion tank, air separator, automac air vent included;

press. reduc. vlv./backow preventer to be sourced locally.

1" Taco Geo-Sentry Zone Valve Y ATEBV5C One per radiant manifold and one per fan coil

Turbomax indirect water

heater

Y See Notes

Must be ordered with unit as part of unit as 45 or 65 gallon

tank

Brass 3-way valve in cabinet Y 03P016001BN

Two are included with unit. Two more should be ordered for

hydronic piping.

Double O-ring x 1" FPT (pair) Y AGA5FPT Two sets should be ordered for external ush valves.

Boiler drain valve Included 11080003001 Part of plumbing kit

Strainer Included 08P020-01NN Internal to Indoor Module

System Pump Y See Notes

AGSIPV3A (UPS26-115V const. spd. insul. cabinet w/isol.

vlvs.) OR: AGSIPV7A (UPM-XL var. spd. 230V insulated

cabinet w/isol. vlvs.) + AGFCVSC2A controller)

Hydraulic Separator Y ATHS6A

Taco copper separator, 1-1/4” sweat w/mounng brackets,

auto air vent, and blow-down valve

Dierenal bypass valve Y ADBV4A Use on hydronic side of hydraulic separator

Air Handler(s) Y See Notes Review Enertech price books for MPH Series air handers

Radiant Tubing/Accessories Y See Notes Review Enertech price books for Inoor products

Oponal elect. or gas wtr htr Y N/A Supplied by contractor

Pressure Relief Valve Included N/A Included with indirect water heater

Ball Valves Y N/A Supplied by contractor

Unions, adapters, misc. ngs Y N/A Supplied by contractor

Pressure gauge N/A N/A Included with indirect water heater

Loading...

Loading...