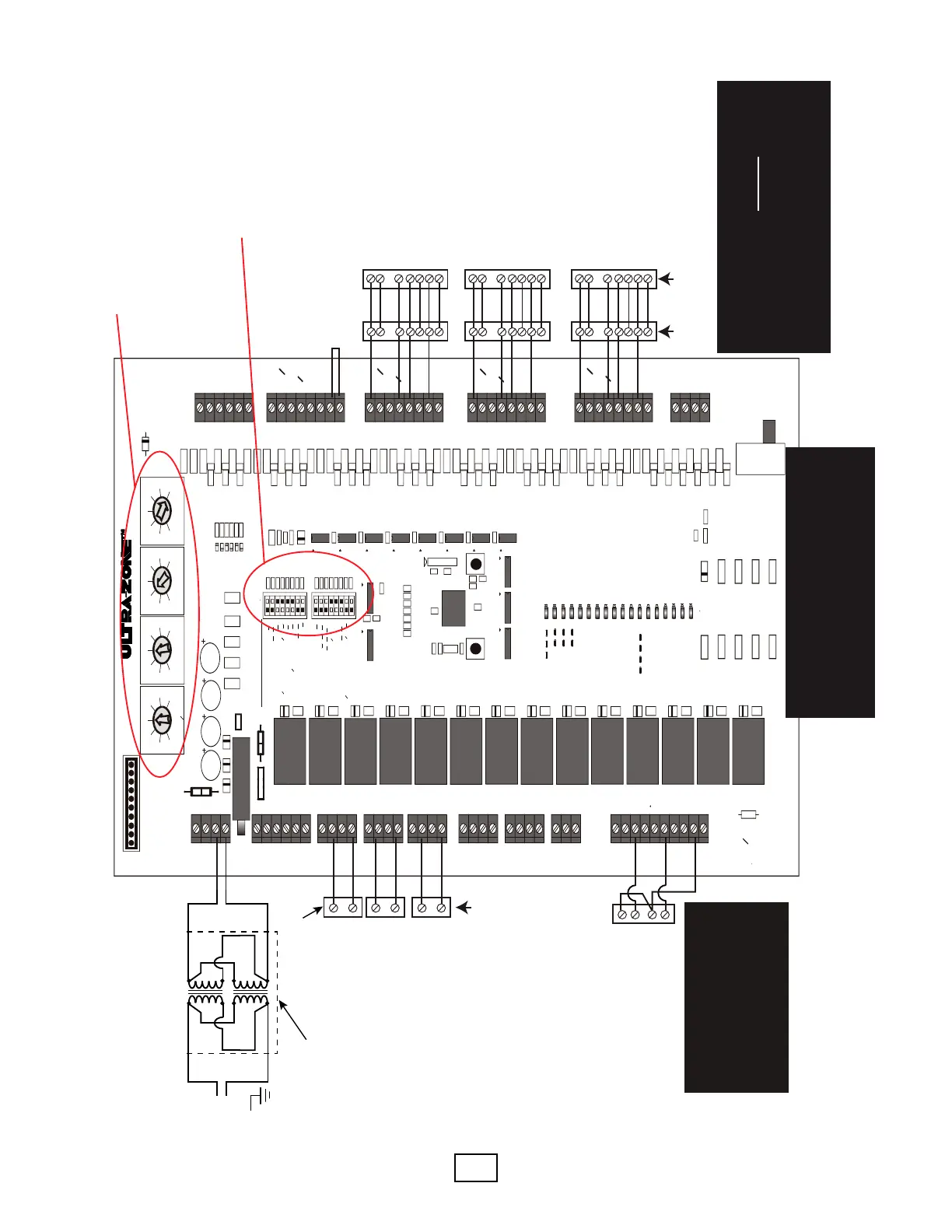

EAV - EME/EMD Rev. A Models

FA

FA

TB1

R

C

JMP1

C1

D1

RESET

CB1

F1

K 1

TB2

MX R

MX C

M6

M2

TB3

4

Z

O

N

E

K 2

M6

M2

2

3

M6

M2

Z

O

N

E

Z

O

N

E

TB4

TB5

K 3 K 4

M6

M2

M6

M4

M2

M1

Z

O

N

E

D

M

P

R

O

A

TB6

1

K 5

TB7

K 7

M6

M4

M2

M1

NC

NO

C

E

B

D

TB8

K 8

K 9

G

Y2

O

B

W 2

E

RH

RC

LI NK

RH

H

V

A

C

S

Y

S

T

E

M

TB9

K 10 K 11

K 12 K 13

JMP3

K 14

W

E

C ONTR OL S INC .

E nglis htown, NJ

HVA C ZO NE

C ONT R OL

S YS TE M

U Z C 4

SA S

SA S

O AS

O AS

RA S

RA S

S

E

N

S

O

R

S

TB1 1

TB1 0

T

S

T

A

T

4

C

W1

W 2

Y2

E

C

W1

W 2

Y2

R

G

E

TB12

T

S

T

A

T

3

C

W1

W 2

Y2

R

G

E

T

S

T

A

T

2

TB13

W 2

R

G

T

S

T

A

T

1

TB14

CO

CO

ON E

ZON E

AUX R

TB15

2

2

EMERGENCY

NORMAL

RA S

SA S

O AS

ST ATU S

LI MIT

LI MIT

LI MIT

ZO NE

ZO NE

ZO NE

ZO NE

OP EN

OP EN

OP EN

OP EN

3

1

2

4

OP ENOA DM PR

DMPR

BYP ASS

AUX RE LA Y

FAN

CO MP RE SS OR 1

CO MP RE SS OR 2

EM ER GE NC Y

W2 H EA T

VAL VE ‘ O’

RE V

W1 H EA T

LED12

LED13

LED14

LED15

LED16

LED17

LED9

LED10

LED18

LED2

LED3

LED1 1

LED4

LED1

LED6

LED5

LED7

LED8

RE SE T

CP U

TIM ER

RE SE T

OFF

SAS

ON

<

>

GA S

FAN

HYDRO

<

>

90

PUR GE

180

s

s

<

>

OA S

STAG ES

TMR

<

>

DF

HP

CONV

< >

HP

GA S

SYS TEM

>

>

OFF

FAN PRG

ON

<

>

OFF

R

%

50

ON

<

>

RA

<

AUX RL Y

>

DA

AN Y

<

FA N C

>

Z

1

OF F

<

ZD L

>

ON

OFF

<

RA S

>

ON

0

RA LM T

+10

>

<

HC

HP

>

TSTAT

>

O

<

RV

>

B

1

2

CS#

>

<

BANK1

BANK2

R1

STA GING

TIMER

OAS

7

OFF

14

21

28

35

42

37

34

40

43

46

49

52

R2

COOLING

LIMIT

1ST

R3

LIMIT

STAGE

HEATING

DIFFE RENTIAL

MULTI

STAGE

HEAT

R4

J1

120

110

130

140

150

160

170

12

19

26

33

40

47

5

D6

D5

D4

R7

R6

R5

D3

JMP 2

D10

D7

D8

D9

R10

R11

R9

R8

D14

D13

D12

D11

R15

R12

R13

R14

D16

D15

R17

R16

R18

R63

R55

R53

R52

R54

R61

R60

Z1

R56

R57

R 19

C2

C54

D2

R 20

R 21

R 22

A

U

X

R

L

Y

C25

C26

C27

R65

R66

R67

R68

R71

R70

R69

R72

R73

R28

R27

R26

R25

R24

R23

D17

D18

D19

D20

D21

D22

R64

C48

C47

C46

C51

C50

C49

C52

SW 3

R134

R128

R129

R130

R130

R132

R133

R135

R127

R126

R125

R124

R123

R122

U17

U18

U19

C42

C41

C40

C45

C44

C43

R121

R120

R119

R118

R117

R116

R115

R114

R113

R112

R111

R110

R109

R108

R107

R106

D23

C3

R29

R30

R31

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R46

R45

R50

C28

C29

C30

C31

C32

C33

C5

C4

U2

U3

U4

R74

R75

R76

R77

R78

R79

R88

R87

R86

R85

R84

R83

R82

R81

R80

C34

C35

C36

C16

C6

C20

U6

U7

U5

R98

R97

R96

R95

R93

R94

R92

R91

R90

R89

C39

C38

C37

C23

C24

U8

U9

R105

R104

R103

R102

R101

R100

R99

J2

C8

C7

C 1 0

C 9

C 11

C 1 2

C 1 3

C 1 4

C 1 5

U15

U14

R47

C17

C21

C 2 2

C 1 9

U1

Y1

SW 2

SW 1

R51

R50

R48

R 49

R58

C18

D

14

18

17

SWITCH LEGEND

D24

R 52

LED19

GROUND FAULT

C53

TRL

C

C

W1

E

Y2

O

Y1

B

O

Y1

B

O

Y1

B

Y1

O

B

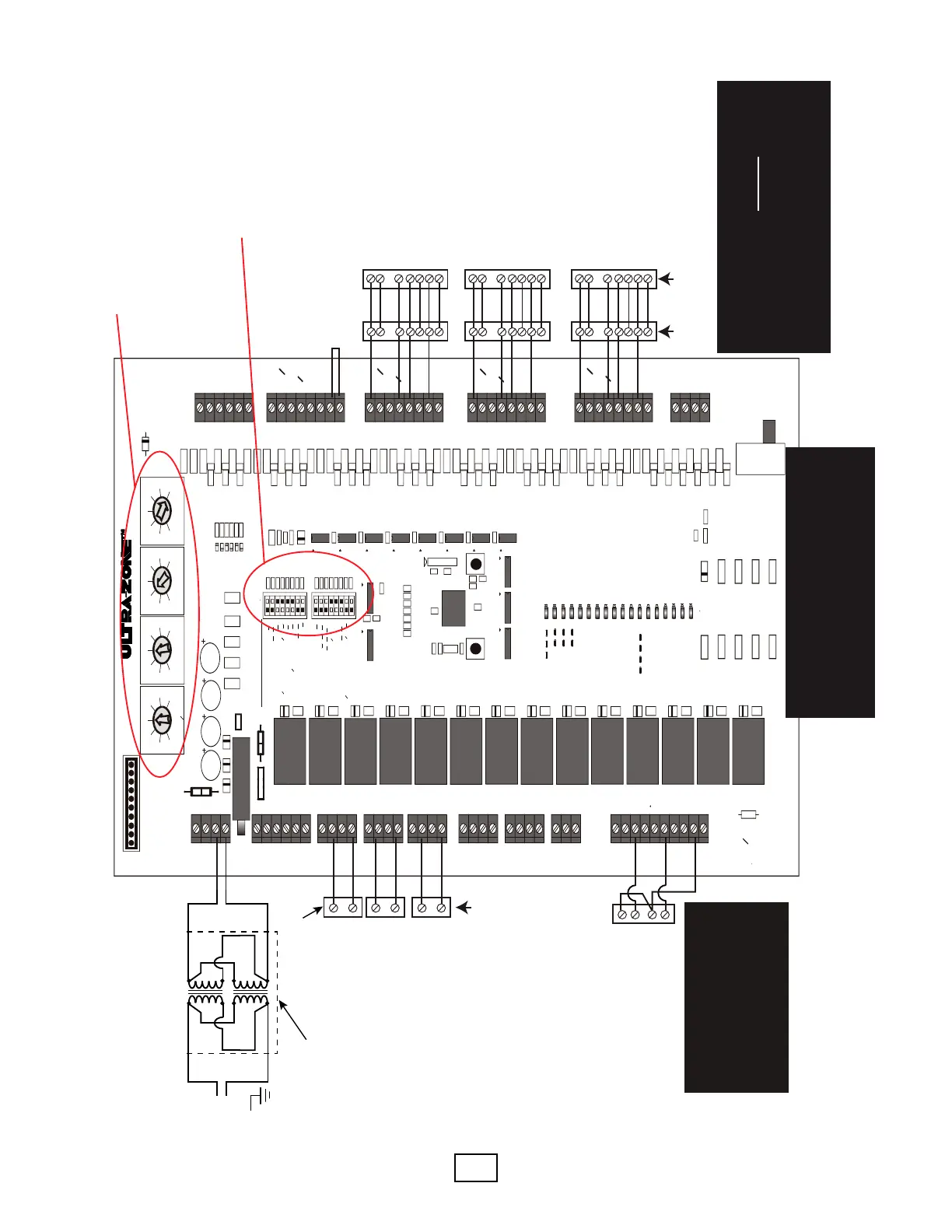

3 heat/2 cool

Heat Pump

Thermostat

Enertech

MPH

Fan Coil

⚠ CAUTION ⚠

TRANSFORMER MUST BE REMOVED FROM EACH

FAN COIL TO AVOID PHASING ISSUES BETWEEN

FAN COILS AND THE ZONE PANEL. WIRING

SHOWN FOR ENERTECH MPH FAN COILS, WHICH

USE HEAT PUMP THERMOSTATS.

RC

EM INDOOR

MODULE

ZONE VALVE NOTES:

The EWC zone panel opens all dampers

when no zones are calling, which is ne

for dampers, but is not optimal for zone

valves. When using zone valves on the

output (left side), zone 4 should be used

as a “control zone” to make sure that the

zone valves will be closed when there is

no thermostat call. For addtional zones,

use a 2-zone expansion panel, Enertech

part # AZZXM-2.

W/Y

C

Taco

Geo Sentry

Zone Valve

W/Y

C

W/Y

C

M4

M1

M4

M1

M4

M1

M4

M1

24V

24V

THERMOSTAT

AND FAN COIL

CONNECTIONS

FOR UP TO

3 FAN COILS

(NOTE 2)

DIAL SETTINGS:

STAGING = OFF

COOLING LIMIT = 43

1ST STAGE LIMIT = 140

MULTI-STAGE = 26

DIP SWITCH SETTINGS:

SYSTEM = GAS

HP = CONV

FAN PRG = OFF

PURGE = 90S

STAGES = TMR

50% RULE = OFF

SAS = OFF

FAN = GAS

TSTAT = HP

CS# = 1

RV = O

ZDL = OFF

AUX RLY = DA

RAS = OFF

RA LIMIT = 0

FAN CTRL = ANY

NEMA enclosure with two 75VA

transformers (Enertech part #

11450000001) wired in parallel

L1

L2

230V

connections

L1

L1

L2

L2

R

R

C

C

Ground

C1

W1

O

Y1

Y2

R

G

C

W1

O

Y1

Y2

R

G

C1

W1

O

Y1

Y2

R

G

C

W1

O

Y1

Y2

R

G

C1

W1

O

Y1

Y2

R

G

C

W1

O

Y1

Y2

R

G

Zone Valves

at Fan Coils

Y1

W 1

NOTE 2

R

G

Secon 8: Field Wiring

Diagram HTGCLG-5: Heang/Cooling

Mulple Fan Coils - No Radiant

(All fan coils are Enertech MPH series)

⚠ CAUTION ⚠

ALL FAN COILS MUST BE 2 TONS OR LARGER FOR

THIS APPLICATION. IF ANY FAN COIL IS SMALLER

THAN 2 TONS, A BUFFER TANK IS REQUIRED

(USE DIAGRAM HTGCLG-7 AND FIGURE 16C).

⚠NOTICE ⚠

THE EM UNIT TERMINALS ARE

POLARITY SENSITIVE. TERMINALS

7 AND 9 ARE COMMON. ENSURE

THAT 7 AND 9 ARE CONNECTED

TO RC AT THE ZONE BOARD.

HHEAT

COOL

7

8

9

10

Loading...

Loading...