Status Messages Installation and Operation Manual - COMTEC

®

6000

44 Doc.-ID: COM6000_11022020_EN

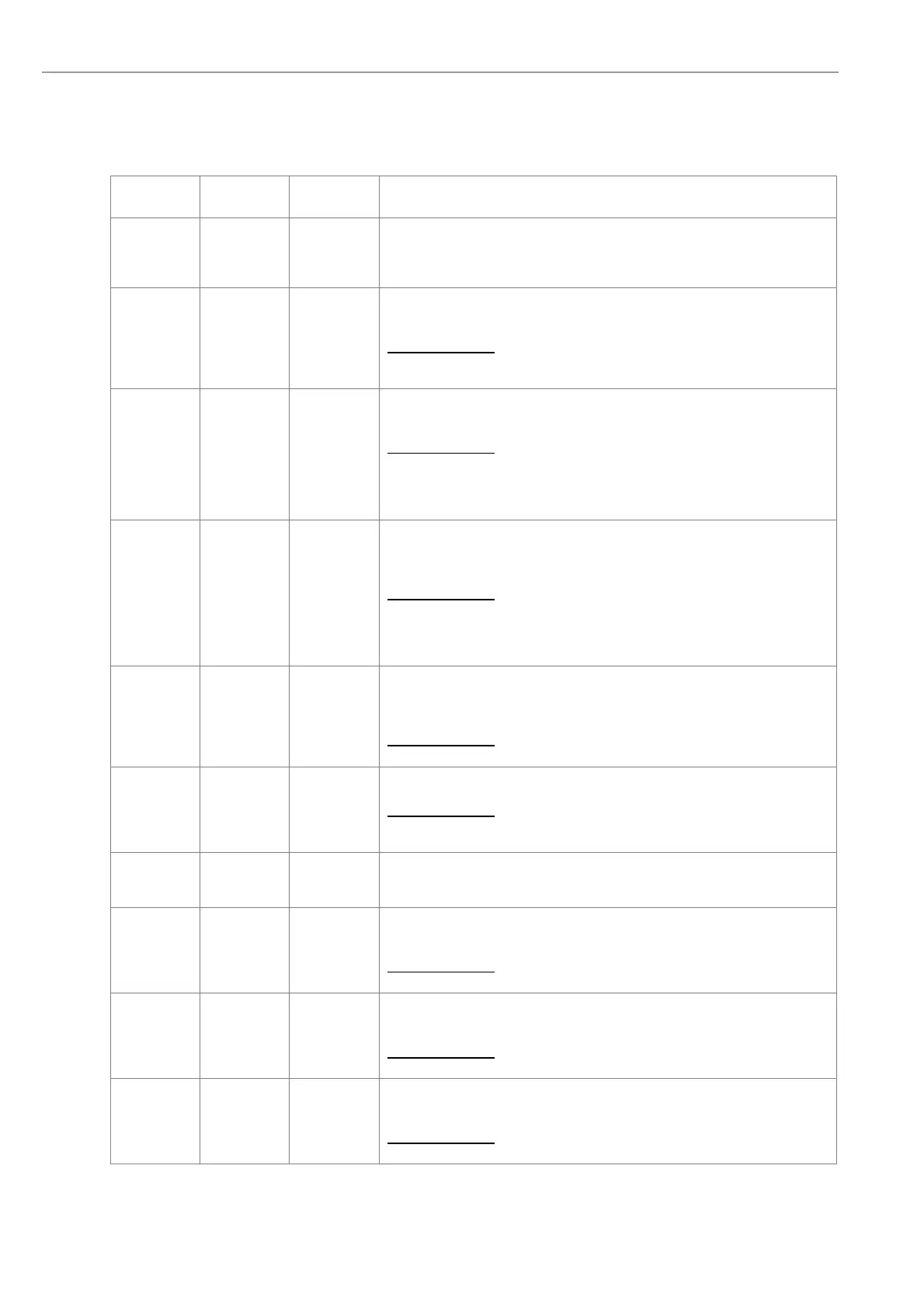

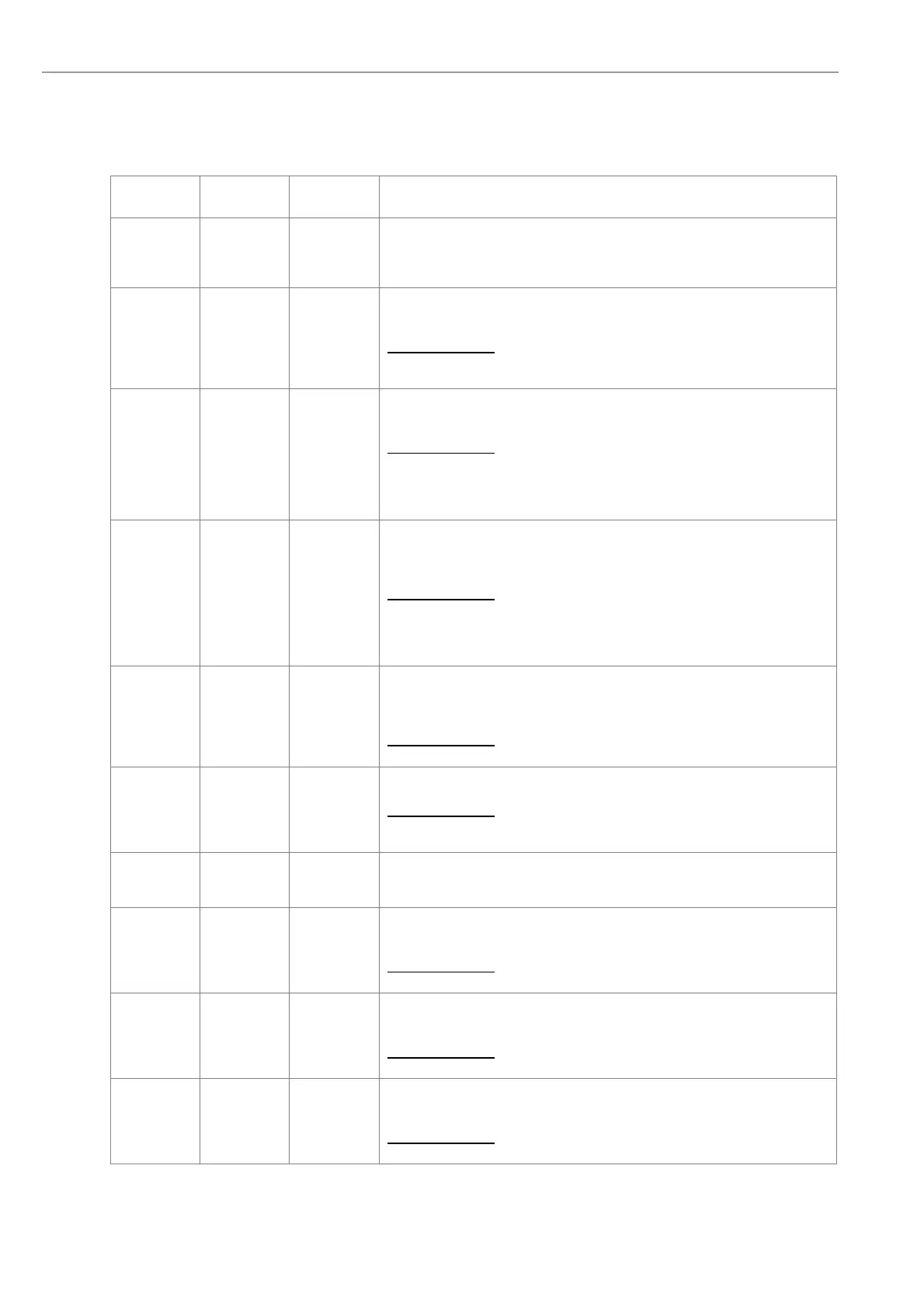

6 Status Messages

6.1 Error Messages

Error

Message

Relay

contact

O

2

signal

output

Description

Hardware

error 1-7

System

error, open

2.00 mA,

when not

set

differently

The error can occur at any time and signalizes a failure of one of the elec-

tronic components. The O

2

sensor heater is switched off. Contact a service

point, if the error returns after restarting the system.

Open circuit

thermocou-

ple

System

error, open

2.00 mA,

when not

set

differently

The error can occur at any time and signals a break in the circuit of the

thermocouple. The O

2

sensor heater is switched off. Once the fault has

been corrected, the error can be reset.

Possible causes: contact problems of the thermocouple wire to the termi-

nal points of the electronics or the sensor, sensor cable is damaged or the

thermocouple is defective.

O

2

probe

set point

temp. not

reached

System

error, open

2.00 mA,

when not

set

differently

The error can occur during the heating of the O

2

sensor (Max. 90 minutes).

The O

2

sensor heater is switched off. An error reset can be carried out by

the user in order to restart the heating process.

Possible causes: F2 fuse defective, contact problem of the O

2

sensor

heater wire to the terminal points of the electronics or the sensor, sensor

cable is damaged, short-circuited thermocouple, reference air flow greater

than 60 l / h, power supply too low, flow rate too high and / or temperature

in the process too low , electronic failure.

O

2

probe

temperature

too low

System

error, open

2.00 mA,

when not

set

differently

The error can occur during measurement, indicating that the O

2

sensor

temperature drops 20 ° C (68 ° F) below the set point temperature. The O

2

sensor heater is switched off. An error reset can be carried out by the user

in order to restart the heating process.

Possible causes: F2 fuse defective, contact problem of the O

2

sensor

heater wire to the terminal points of the electronics or the sensor, sensor

cable is damaged, short-circuit thermocouple, reference air flow greater

than 60 l / h, power supply too low, flow rate too high and / or temperature

in the process too low, electronic failure.

O

2

probe

temperature

too high

System

error, open

2.00 mA,

when not

set

differently

The error can occur during measurement, indicating that the O

2

sensor

temperature has risen 20 ° C (68 ° F) above the set point temperature. The

O

2

sensor heater is switched off. An error reset can be carried out by the

user in order to restart the heating process.

Possible causes: Process temperature too high, O

2

sensor cable to the

transmitter connected incorrectly, electronic failure.

Open circuit

O

2

sensor

System

error, open

2.00 mA,

when not

set

differently

The error can occur at any time and signals a break in the circuit of the O

2

sensor. Once the fault has been corrected, the error can be reset.

Possible causes: contact problem of the O

2

sensor wire to the terminal

points of the electronics and the probe, probe cable is defective, contact

problem of the probe the inner part of the O

2

sensor.

O

2

sensor

calibration

failed

System

error, open

O

2

sensor calibration has failed for one of the following reasons. An error

reset can be carried out by the user. All corresponding entries are then

reset as well.

Test gas

flow rate too

low

System

error, open

The error can occur during an O

2

sensor calibration and signals an insuffi-

cient test gas flow. An error reset can be carried out by the user. A suc-

cessful re-calibration also resets the error.

Possible causes: test gas bottle empty, test gas flow incorrectly set,

instrument air supply to the system does not exist.

Test gas

flow rate too

high

System

error, open

The error can occur during an O

2

sensor calibration and signals a test gas

flow which is too high. An error reset can be carried out by the user. A

successful re-calibration also resets the error.

Possible causes: test gas bottle empty, test gas flow incorrectly set, in-

strument air supply to the system does not exist.

O

2

sensor

offset too

low

System

error, open

The error can only occur only during an O

2

sensor calibration. An error

reset can be carried out by the user. A successful re-calibration also resets

the error.

Possible causes: inadequate reference air supply, process pressure is too

high, incorrect test gas, O

2

sensor defective.

Loading...

Loading...