Why does my Enotec COMTEC 6000 Analytical Instruments show high O2 and low COe readings?

- MMelinda WalkerAug 4, 2025

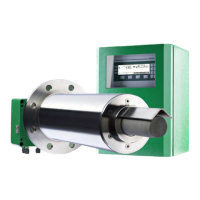

If your Enotec Analytical Instruments' O2 readings are higher than expected while COe readings are lower, this could be due to a poor seal of the CO sensor coupling located in the terminal box housing. Try tightening or replacing the CO sensor coupling assembly.