VT6L Maintenance 8. Cable

VT series Maintenance Manual Rev.2 45

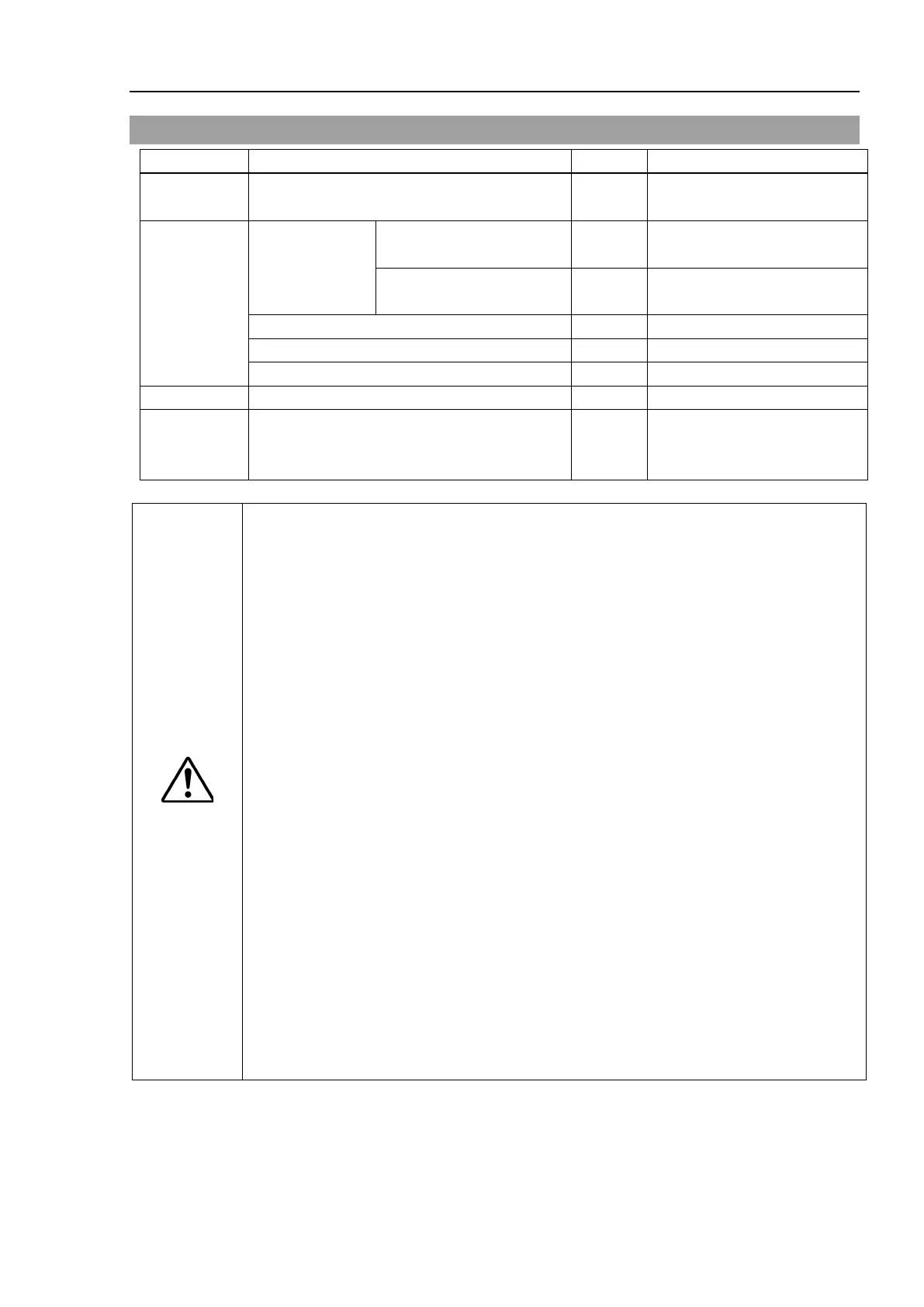

8.1 Replacing Cable Unit

Maintenance

part

Cable Unit 1 2191349

Tools

Hexagonal

wrench

width across flats: 2.5 mm 1

For M3 hexagon socket head

cap bolts

width across flats: 3 mm 1

For M4

hexagon socket head

cap bolts

For tightening torque control

Cross-point screwdriver (No. 2)

Grease GPL-224 -

For purchasing grease, please

contact the supplier of your

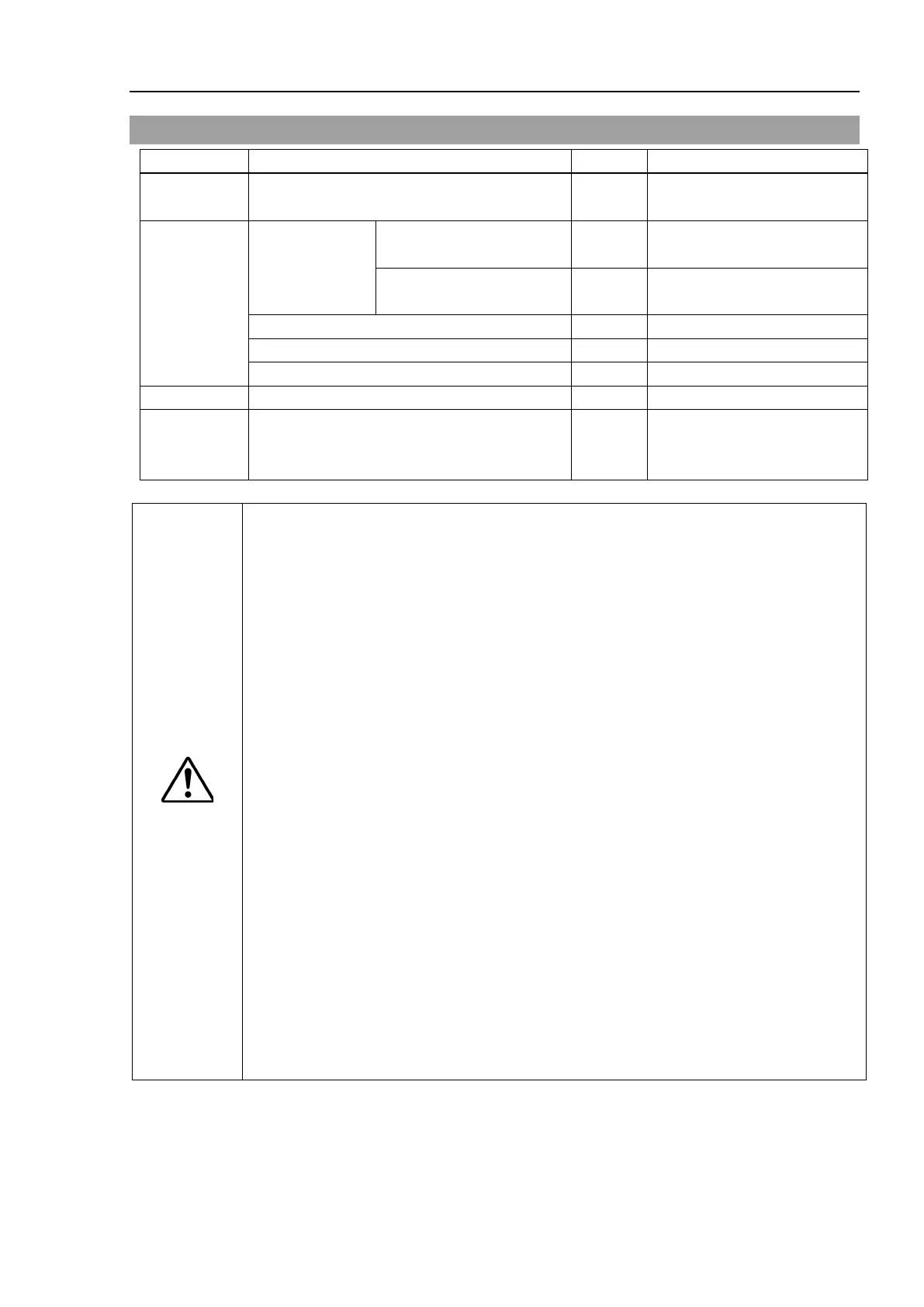

CAUTION

■

If the connectors have been disconnected during the replacement of the cable unit,

b

e sure to reconnect the connectors to their proper positions. Refer to the wiring

Improper connection of the connectors may result in improper

function of the robot

For details on the connections, refer to the following manual.

“3. Manipulator Structure”

Be sure to connect the cables

completely. Do not allow unnecessary strain on the

put heavy objects on the cables. Do not bend or pull the cables

y.) The unnecessary strain on the cables may result in damage to the

cables, disconnection, and/or contact failure. Damaged c

ables, disconnection, or

contact failure is extremely hazardous and may result in electric shock and/or

improper function of the robot system.

Wear protective gear including a mask, protective goggles, and oil

-resistant gloves

If grease gets into your eyes, mouth, or on your skin, follow the

If grease gets into your eyes

: Flush them thoroughly with clean water, and then see a doctor

immediately.

If grease gets into your mouth

: If swallowed, do not induce vomiting. See a doctor immediately.

: If grease just gets into your mouth, wash out your mouth with water

thoroughly.

If grease gets on your skin

Wash the area thoroughly with soap and water.

When removing the Joint #2 motor unit, tilt the Arm #2 and press it against the Arm #1.

Reference: 10.1 Joint #2 - Replacing the Motor, Removal step (2)

When removing the Joint #3 motor unit, tilt the Arm #3 and press it against the Arm #2.

Reference: 11.1 Joint #3 - Replacing the Motor, Removal step (2)

Loading...

Loading...