VT6L Maintenance 2. General Maintenance

VT series Maintenance Manual Rev.2 9

2.3 Tightening Hexagon Socket Head Cap Bolts

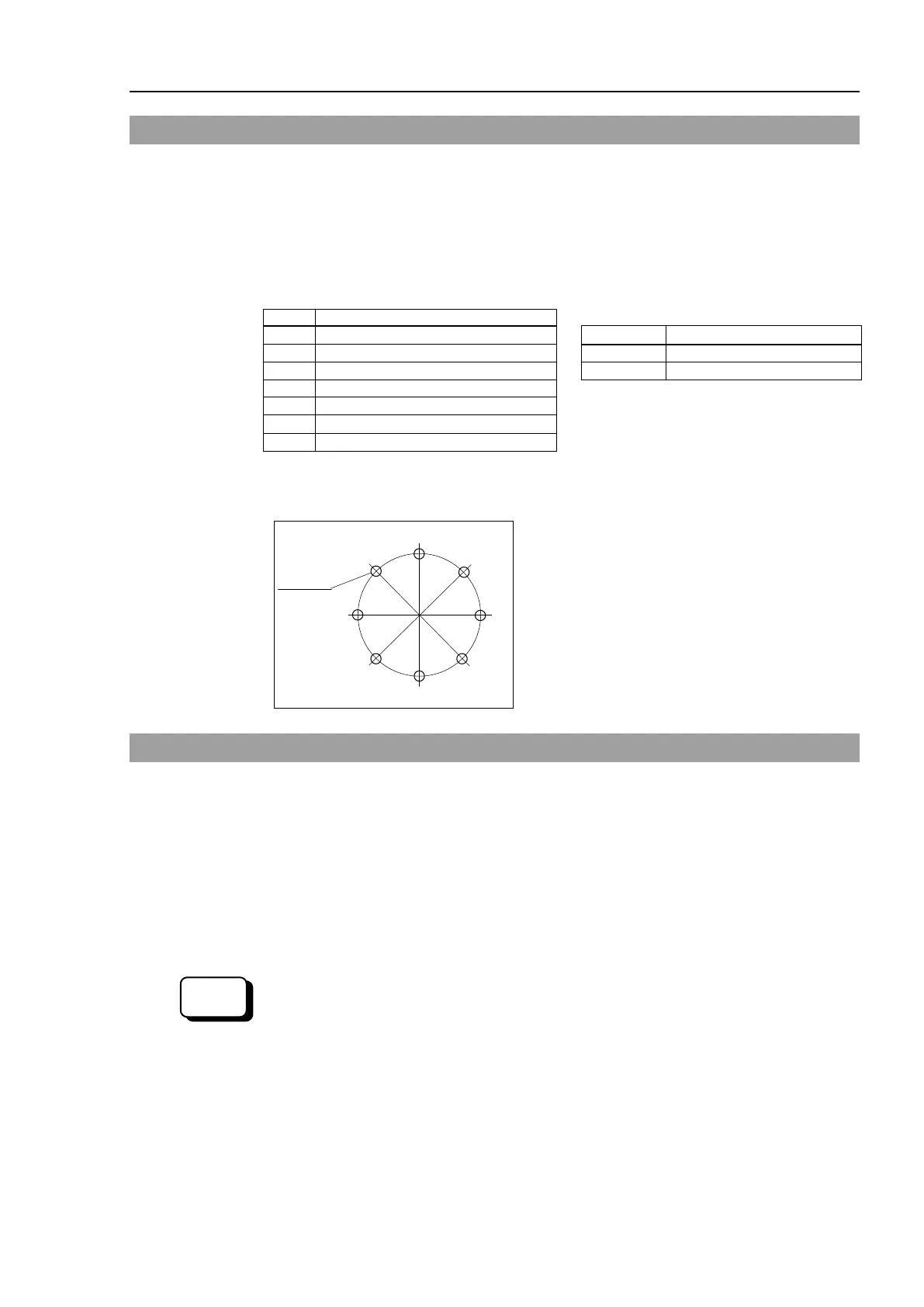

Hexagon socket head cap bolts (herein after referred to as bolt) are used in places where

mechanical strength is required. These bolts are fastened with the tightening torques

shown in the following table.

When it is necessary to refasten these bolts in some procedures in this manual (except special

cases as noted), use a torque wrench so that the bolts are fastened with the appropriate

tightening torques as shown below.

Refer below for the set screw.

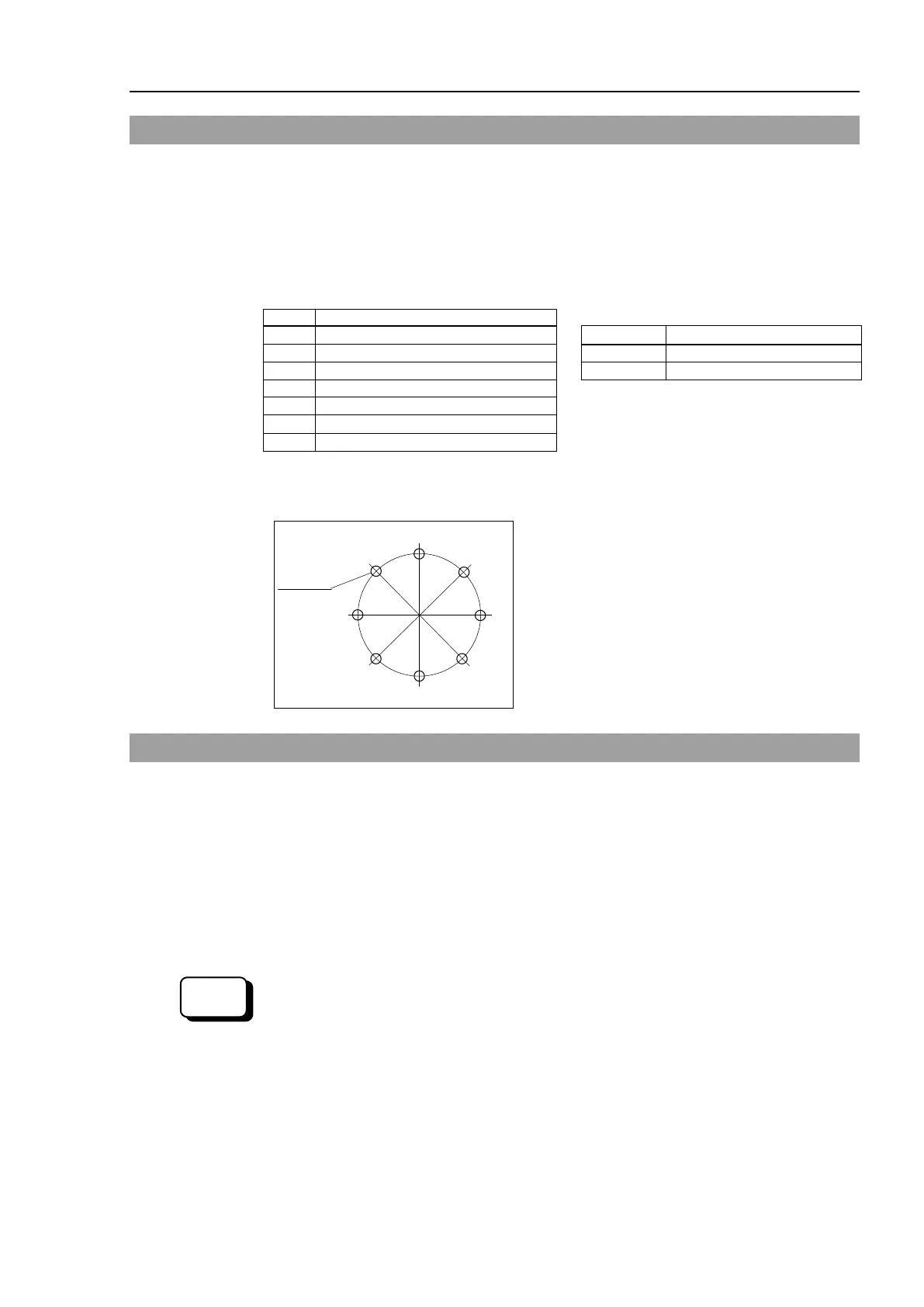

The bolts aligned on a circumference should be fastened in a crisscross pattern as shown in

the figure below.

Do not fasten all bolts securely at one time.

Divide the number of times that the bolts are

fastened into two or three and fasten the bolts

securely with a hex

agonal wrench. Then, use a

torque wrench so that the bolts are fastened with

tightening torques shown in the table above.

2.4 Matching Origins

After parts have been replaced (e.g. motor units, reduction gear units, timing belts), the

Manipulator cannot operate properly because a mismatch exists between the origin stored

in each motor and its corresponding origin stored in the Robot system.

Because of that, it is necessary to perform calibration (encoder rest and calibration) to match

these origins.

For calibration, the pulse values for a specific position must be recorded in advance.

Before replacing parts, select easy point (pose) data from the registered point data to check

the accuracy. Then, follow the steps below to display the pulse values and record them.

Execute the following command from the [Command Window].

>PULSE

PULSE: [Joint #1 Pulse value] pls [Joint #2 Pulse value] pls

pls [Joint #4 Pulse value] pls[Joint #5 Pulse value]pls [Joint #6 Pulse value]pls

Loading...

Loading...