4 MIG/MAG WELDING

0460 896 274

- 23 -

© ESAB AB 2013

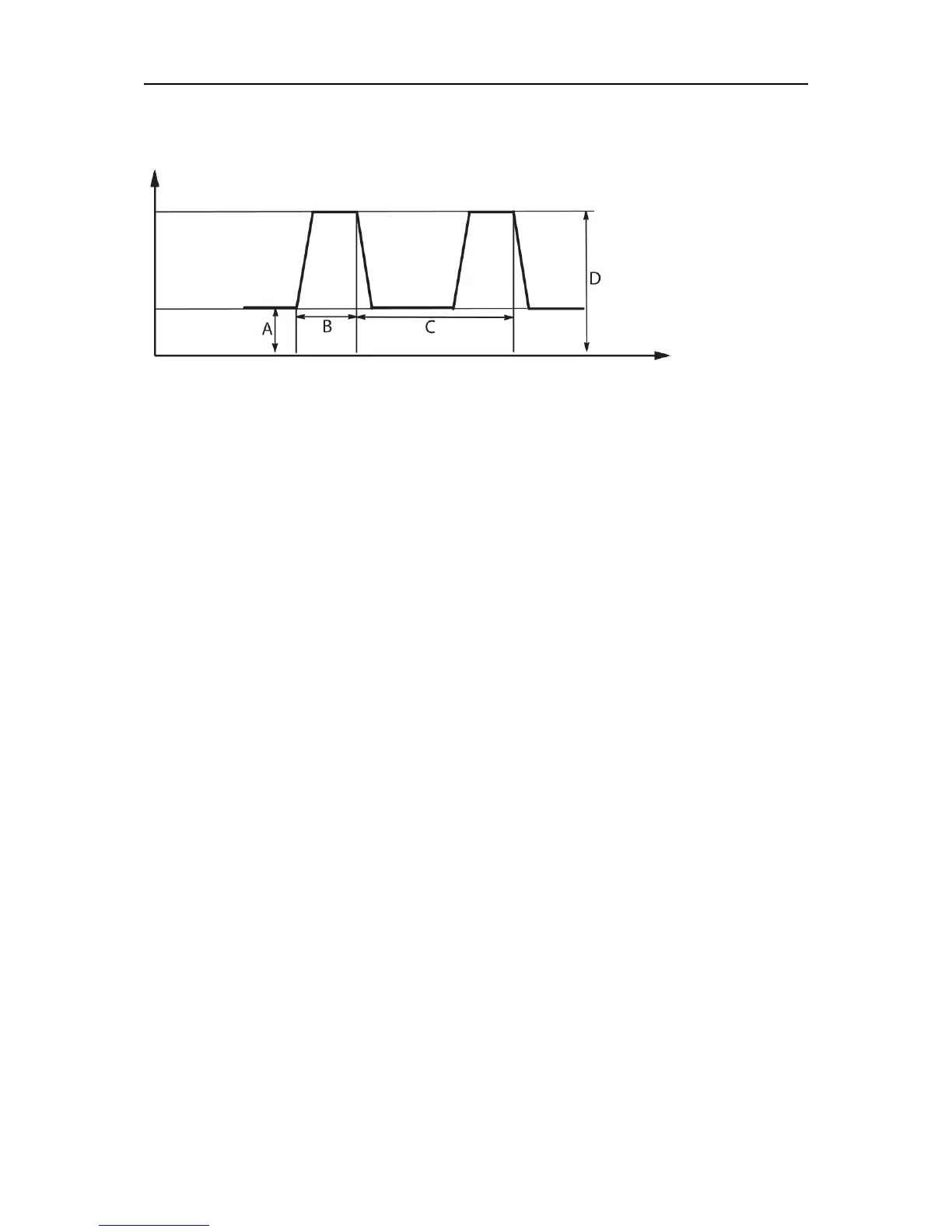

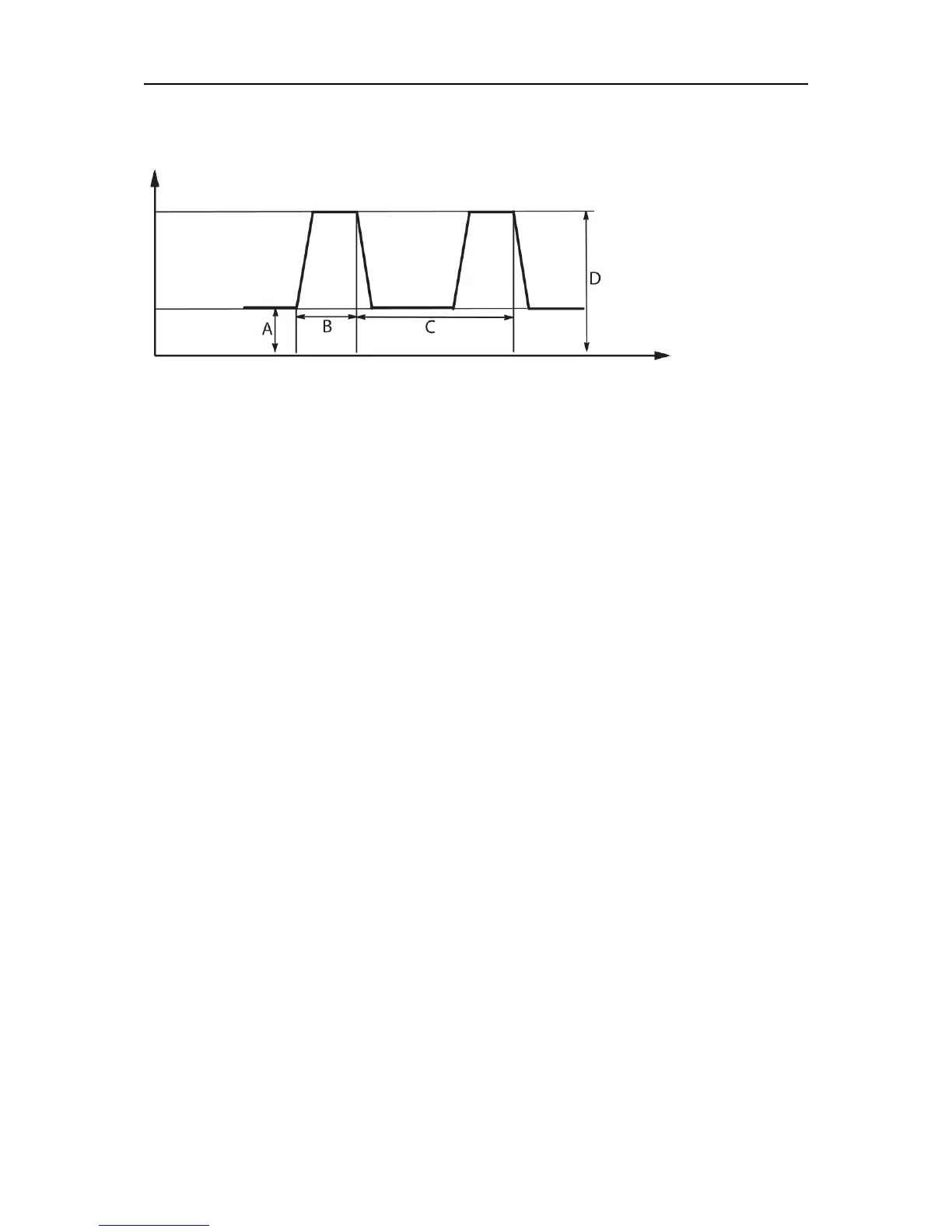

Current

Time

MIG/MAG welding with pulsing

A = Background current

B = Pulse time

C = Pulse period time

D = Pulse current

Slope

“Slope” means that the pulse current slowly increases/decreases to the set value. The

“Slope” parameter can be set in nine stages, with each stage corresponding to 100 μs.

The slope is important as regards the sound. A steep slope produces a louder and sharper

sound. Too gentle a slope can, in the worst case scenario, impair the pulse's ability to cut off

the droplet.

Slope is set in the weld data setting menu with the synergy function switched off.

Only applies to MIG/MAG welding with pulsing.

Ka

Ka is the proportional element and corresponds to the regulator's amplification. A low value

means that the voltage is not maintained at a constant level as precisely.

Ka is set in the weld data setting menu → internal constants with the synergy function

switched off.

Only applies to MIG/MAG welding with pulsing.

Ki

Ki is the integrating element that attempts in the longer term to eliminate the fault. Here too,

a low value will produce a weaker regulatory effect.

Ki is set in the weld data setting menu → internal constants with the synergy function

switched off.

Only applies to MIG/MAG welding with pulsing.

Loading...

Loading...