7 ARC AIR GOUGING

0460 896 274

- 41 -

© ESAB AB 2013

7 ARC AIR GOUGING

Main menu → Process

With arc air gouging, a special electrode comprising a carbon rod with a copper casing is

used.

An arc is formed between the carbon rod and the workpiece, which melts the material. Air is

supplied so that the melted material is blown away.

The following electrode diameters can be selected for arc air gouging: 4.0, 5.0, 6.0, 8.0, 10

and 13 mm.

Arc air gouging is not recommended for power sources below 400 A.

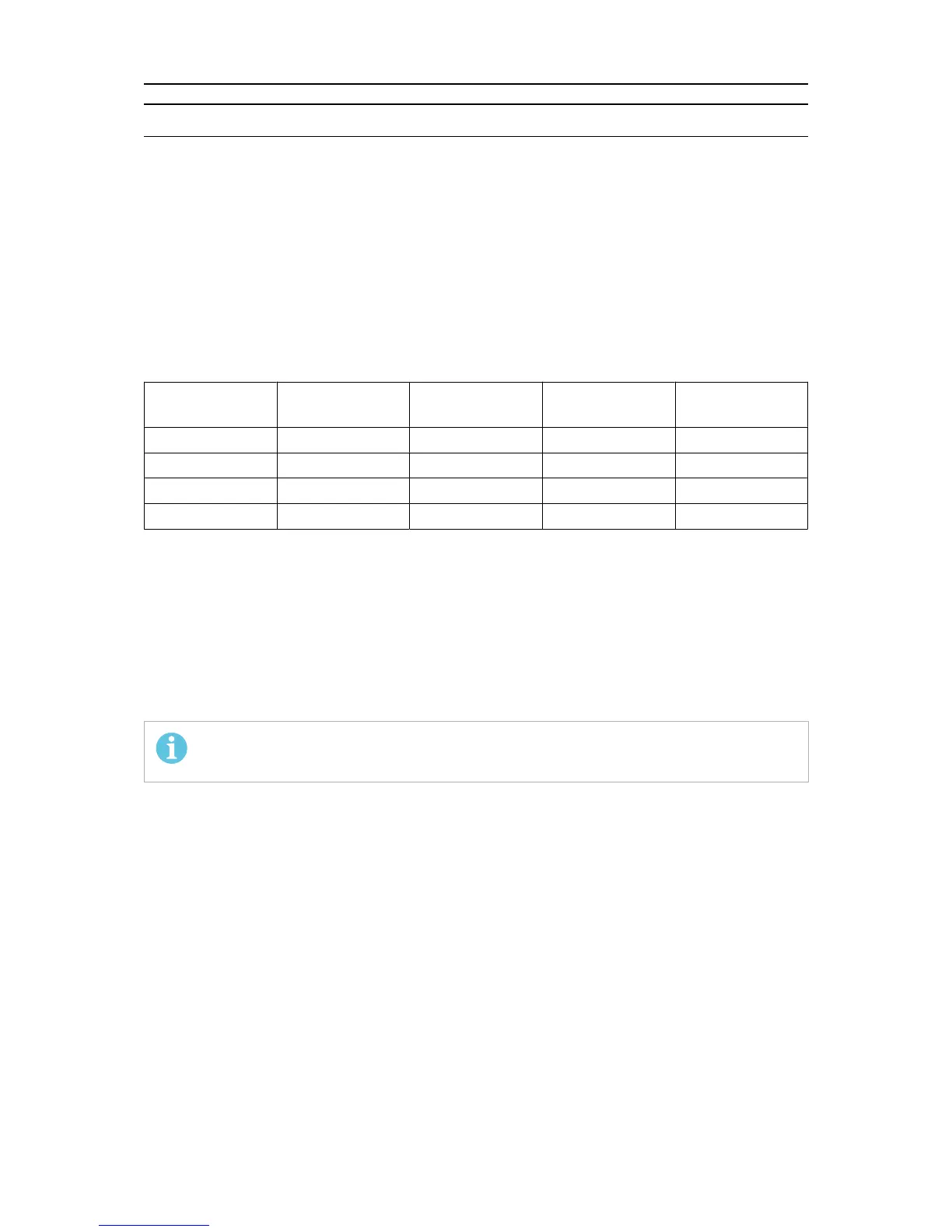

7.1 Settings in the weld data setting menu

Settings Setting range In steps of Synergy

dependent

Adjustable in

synergy

Voltage 8 - 60 V 1 V x x

Synergy* OFF or ON - - -

Inductance 0 - 100% x

Regulator type 1 - 12 1 x

*) The synergic line on delivery: 5.0 mm electrode (carbon rod).

7.2 Function explanations

Voltage

A higher voltage produces a wider weld pool, with better penetration into the workpiece.

The voltage is set in the measure screen, weld data setting or fast mode menus.

Inductance

NOTE!

The setting should not be altered.

Regulator type

Affects the short circuit process and heat in the weld.

The setting should not be altered.

Loading...

Loading...