4 MIG/MAG WELDING

0460 896 274

- 28 -

© ESAB AB 2013

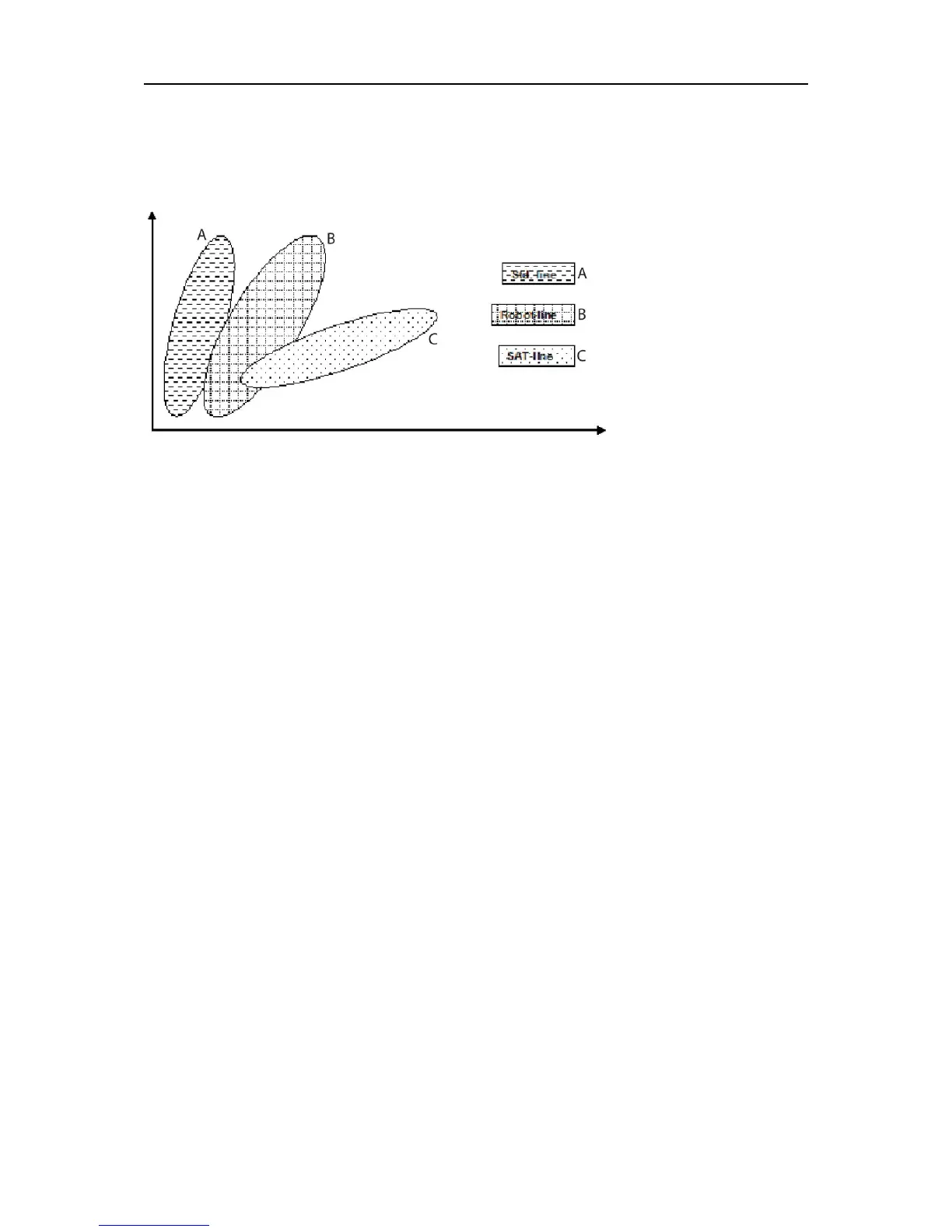

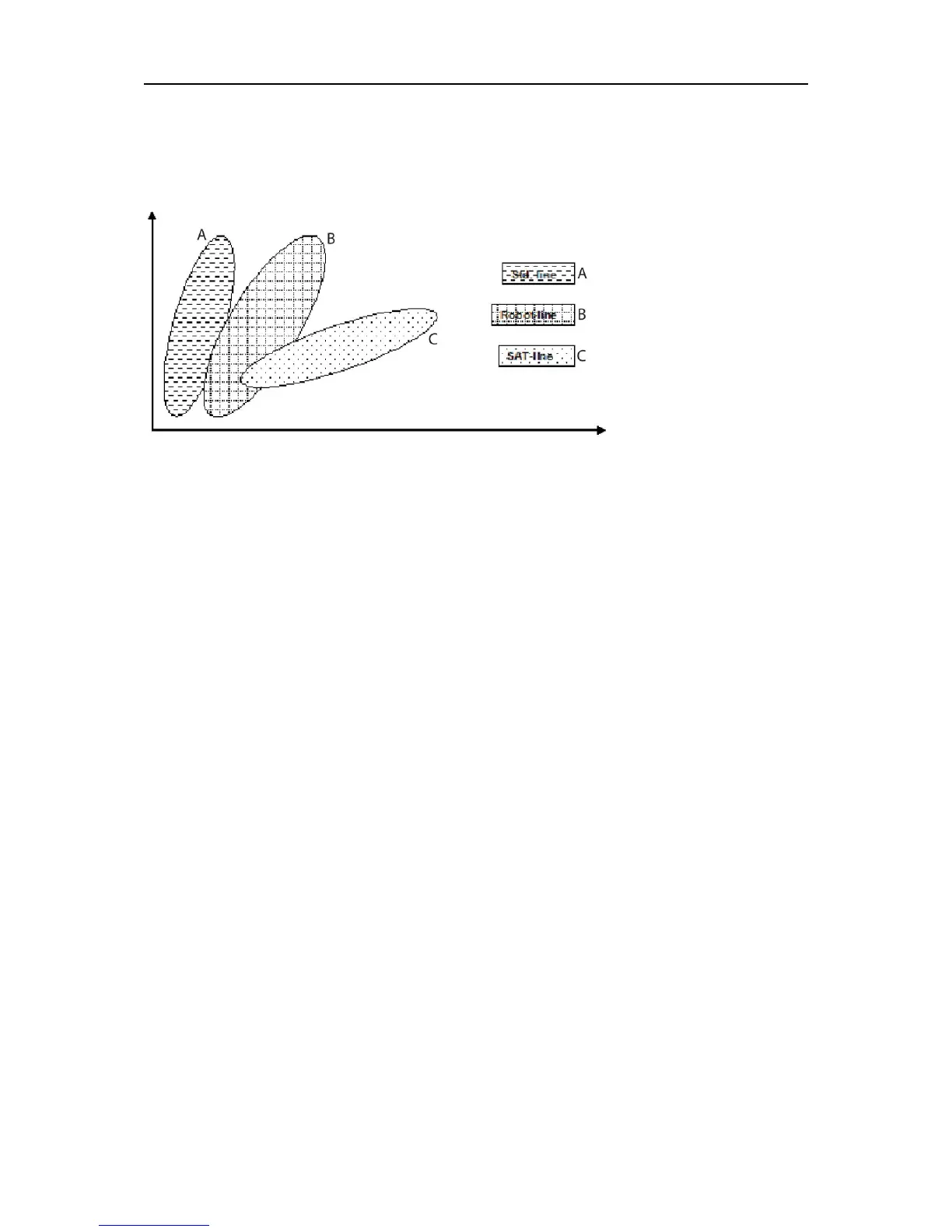

The relationship between welding speed and plate thickness for the various synergy

groups:

Plate thickness

A = STANDARD line

B = ROBOT line

C = SAT line

Welding speed

The ROBOT synergy group is used for robotic welding or other mechanised welding. It is

suited for higher transfer speeds than when welding on standard lines.

SAT stands for Swift Arc Transfer. This synergy group is suitable for high transfer-speeds,

for extreme angles and for plate thicknesses of 2–3 mm.

For wire and gas combinations for SAT, see the "WIRE AND GAS DIMENSIONS" appendix

at the end of this manual.

The synergy group is set in the weld data setting menu for process MIG/MAG.

4.3 SuperPulse

Main menu → Process → Method

The SuperPulse method is used for improved control of the weld pool and the solidification

process. The weld pool has time to solidify partially between each pulse.

Benefits of using SuperPulse:

• Less sensitivity to root gap variations

• Better control of the weld pool during position welding

• Better control of penetration and penetration profile

• Reduced sensitivity tu uneven heat conduction

SuperPulse can be seen as a programmed changeover between two MIG/MAG settings. The

time intervals are determined by the primary and secondary phase time settings.

Welding always starts in the primary phase. When hot start is selected, primary data will be

used during the hot start time in addition to the phase time for the primary data. Crater filling

is always based on secondary data. When a stop command has been activated during the

primary phase time, the process immediately switches to secondary data. The weld

completion is based on secondary data.

Loading...

Loading...