10 TOOLS

0460 896 274

- 75 -

© ESAB AB 2013

10.8.1 Specify voltage/wire co-ordinates

In order to create a synergic line for the short-/sprayarc method, four co-ordinates are

required; for the pulsing method, two co-ordinates are required. These co-ordinates must

then be saved under separate weld data numbers in the weld data memory.

Short-/Sprayarc

• Bring up the main menu and select the MIG/MAG method SHORT/SPRAY.

• Key in the desired values for voltage and wire feed speed for the first co-ordinate.

• Bring up the MEMORY menu and store the first co-ordinate on any number.

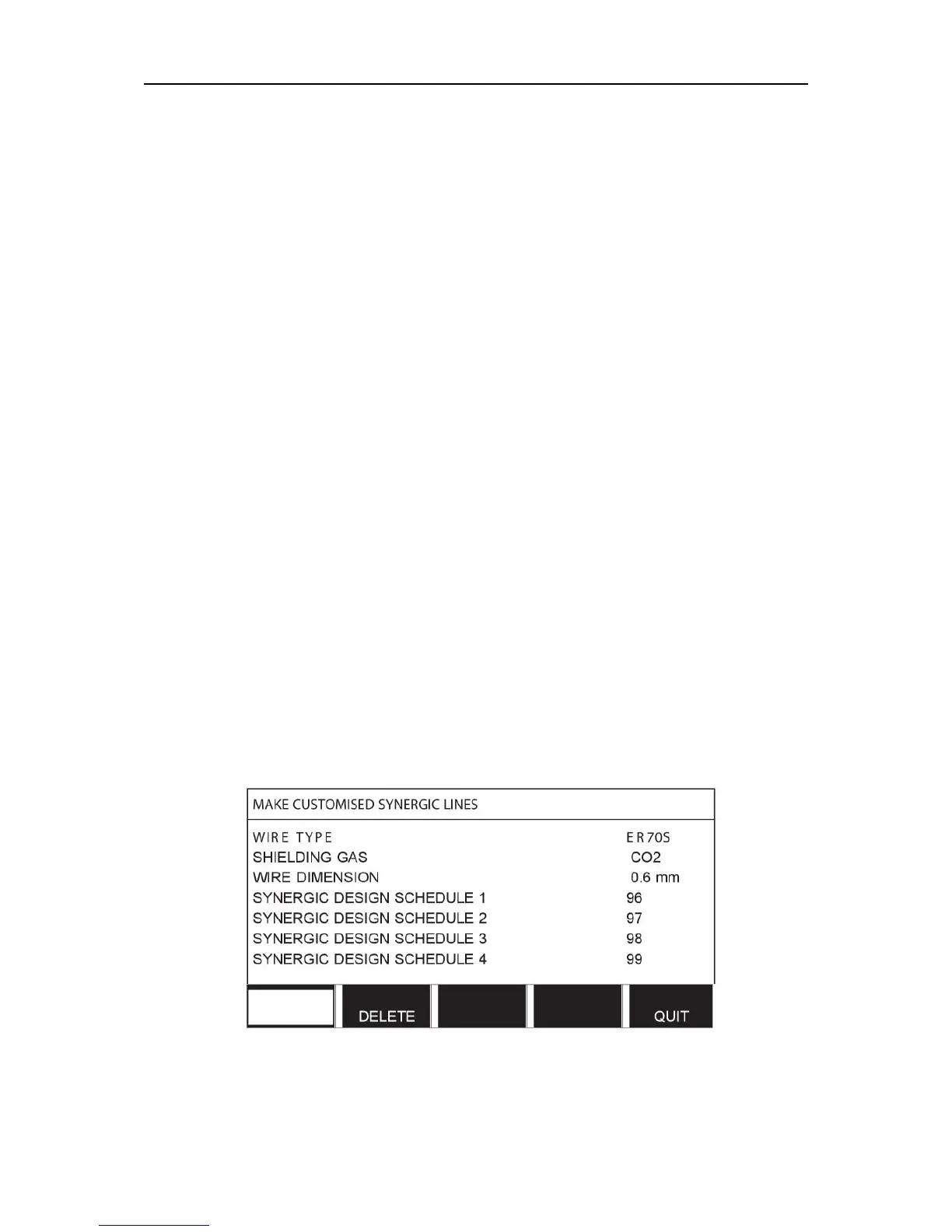

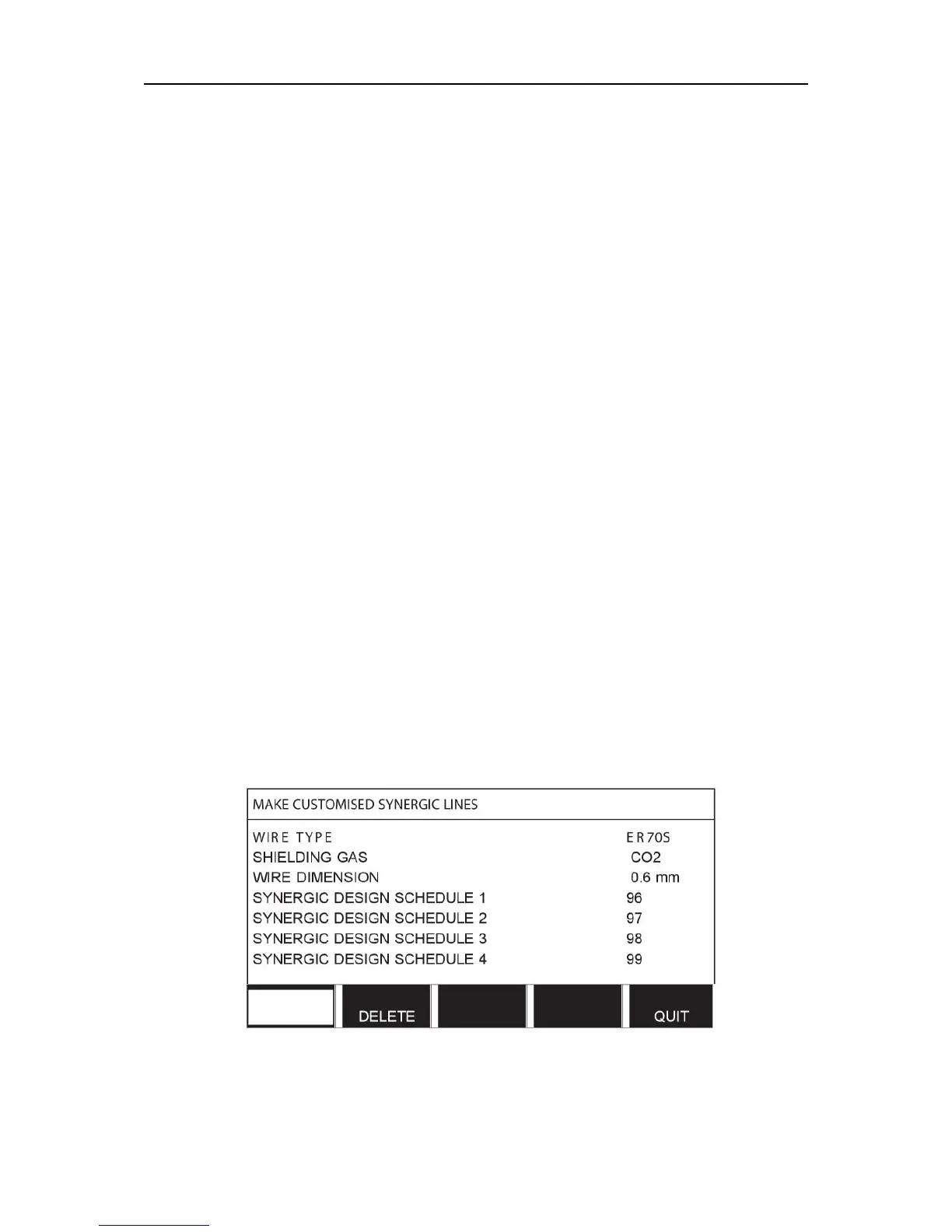

The four co-ordinates for a short-/sprayarc line can be saved as any numbers. When

supplied from the factory, they are saved as numbers 96, 97, 98 and 99.

A higher weld data number should contain higher values for voltage and wire feed speed

than the nearest preceding weld data number.

The welding parameters inductance and regulator type must have the same value in all

four weld data numbers.

• Define the number of co-ordinates that are required and then proceed to the “Specify

valid wire/gas combination” section.

Pulsing

• Bring up the main menu and select the MIG/MAG method PULSING.

• Key in the desired values for voltage and wire feed speed for the first co-ordinate.

• Bring up the MEMORY menu and store the first co-ordinate on any number.

A higher weld data number should contain higher values for voltage, wire feed speed,

pulse frequency, pulse amplitude and background current than the nearest preceding

weld data number.

The welding parameters pulse time, Ka, Ki and “slope” must have the same value in both

weld data numbers.

• Define the number of co-ordinates that are required and then proceed to the “Specify

valid wire/gas combination” section.

10.8.2 Specify valid wire/gas combination

Position the cursor on the WIRE TYPE row and press ENTER.

Loading...

Loading...