Victor Xu Page 32 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

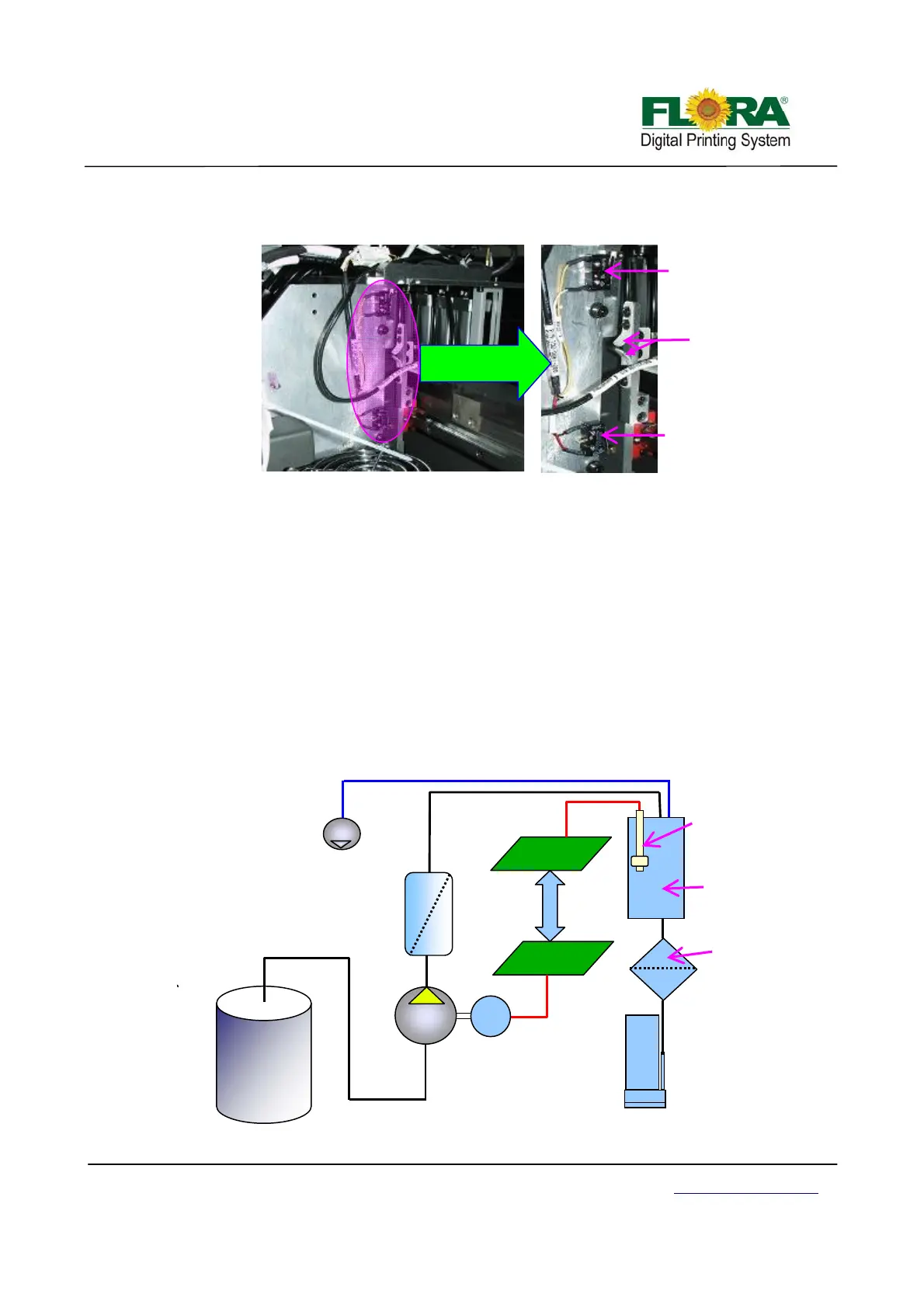

lower limit switch and the upper limit switch control the carriage highest and lowest allowable

height the carriage can move respectively.

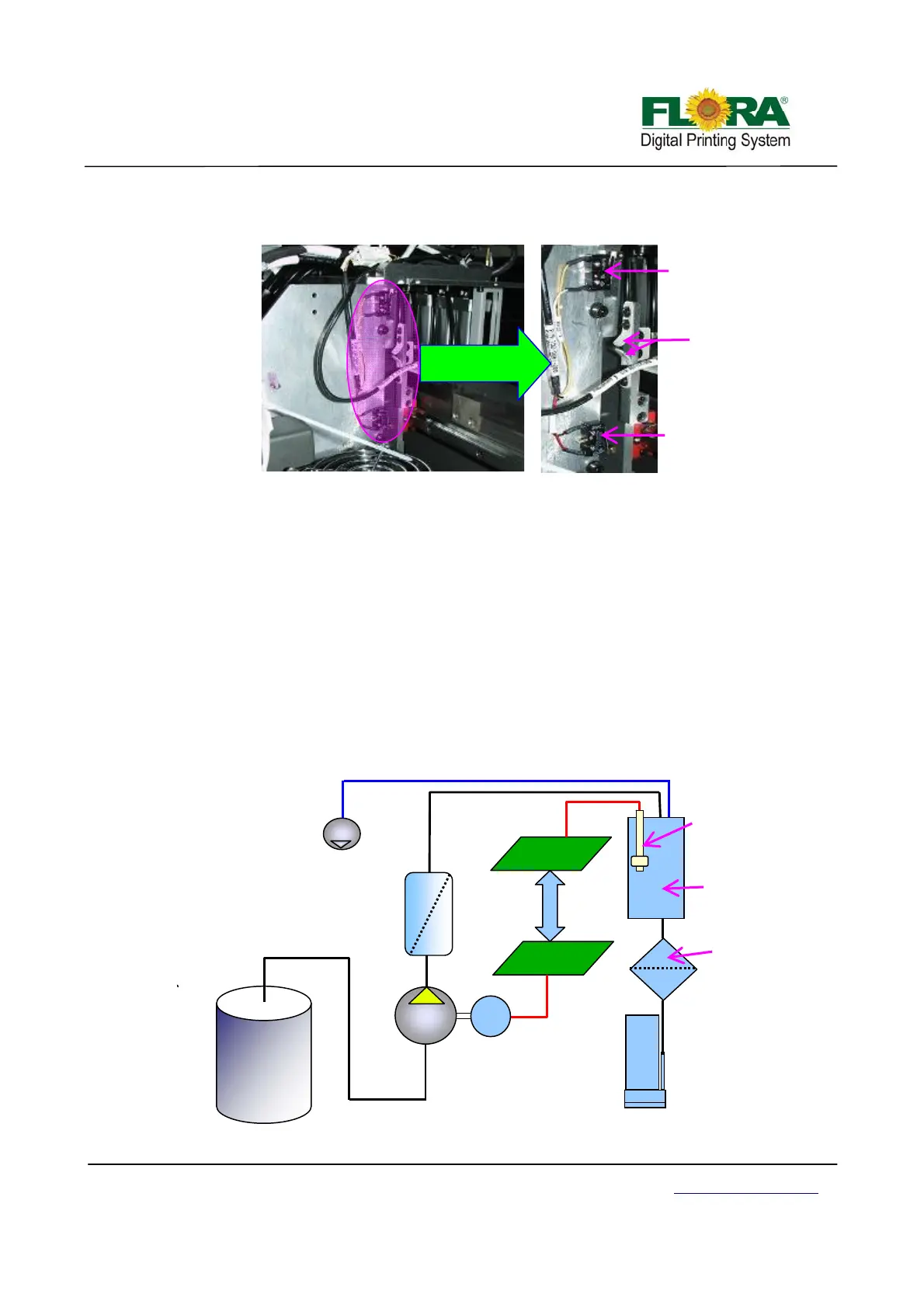

4.5 Ink supply& negative pressure system

4.5.1 Ink supply system

The ink Bottle/Barrel serves as the main reservoir for ink supply, should be refilled in a timely

manner so continuous supply of ink will not be interrupted during printing. The level of ink inside

the bottle/barrel can be monitored visually or using the buzzer system. Refilling is done manually.

The ink pumps suck and discharge the ink into the secondary ink tank. A five-micron filter is

being provided to prevent the secondary tank from being contaminated by unwanted particles,

which are inherent in the ink. Ink level sensor inside the secondary ink tank sends an open or close

contact signal to the Print head control board and Ink control board to control the operation of the

pumps. An optional micro filter is added to enhance the filtering of ink before it flows into the print

heads.

Every time the print heads eject/fire ink droplets, the ink flows and fills the space left by

droplets. A negative pressure system is responsible for holding the ink from flowing out of the print

head nozzles.

Last Chance

Filter

Secondary

Ink Tank

Ink Filter

(Barrel Type)

Ink Level

Sensor

Negative

Pressure

Pump

Ink Control System

Ink Barrel

Printhead

Control Board

Servo Driver

Control Board

M

Ink

Pump

Enlarged View

Carriage minimum

height limit switch

Carriage maximum

height limit switch

Switch

actuators

Right Side of the Carriage

Loading...

Loading...