Victor Xu Page 47 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

Note: The actual reading for both Voltage and Temperature will appear only when the

Read Button is click.

¾ To change the temperature setting simply over write the existing value with your

desired value then click Write button. While for Voltage you need to click the Set

button to update the Voltage setting to your desired value.

¾ Other factors than can influence print quality are:

Room Temperature

Humidity

Ink Viscosity

Negative Pressure Settings

Carriage Printing Speed

Note:

In most difficult cases playing with Uni-direction and at slower speed can help improve

the print quality significantly.

5.5.3 Print head alignment

This is to describe the proper procedure in aligning the Print heads. Before alignment ensure

the nozzle test is perfect!

¾ Perform Ink Prime by activating the toggle switch. Do ink bleeding one print head at

time to remove air bubbles trapped inside the print head.

¾ Perform auto clean for print heads thru maintenance switch on the control panel or

from the Flora driver GUI.

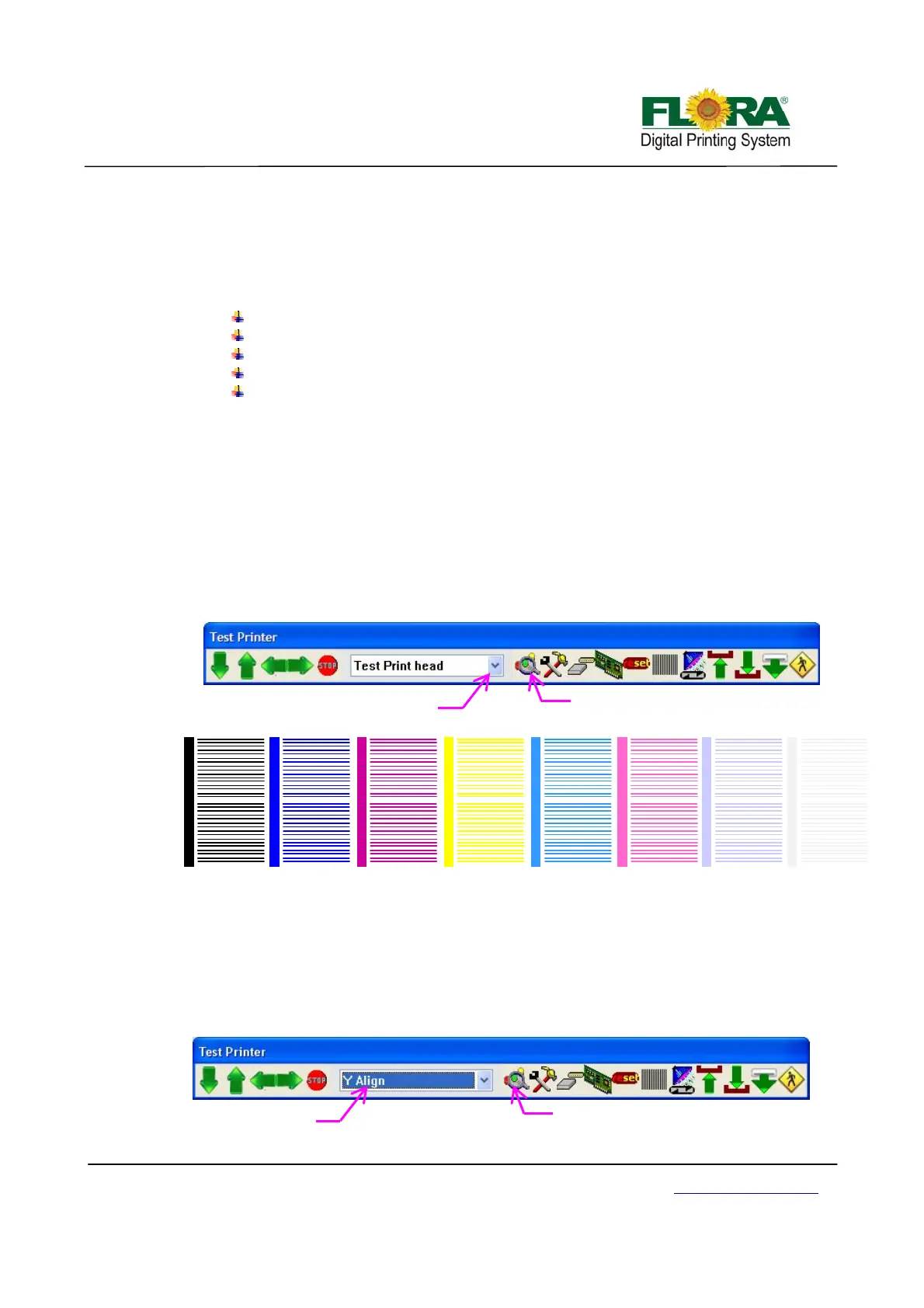

¾ Send Test Print head to see if all print heads prints a shown below;

Note: Above is an Illustration of Nozzle Test Print, only three colors are shown due to

space constraint, Yellow, White and Varnish print heads must print the same result.

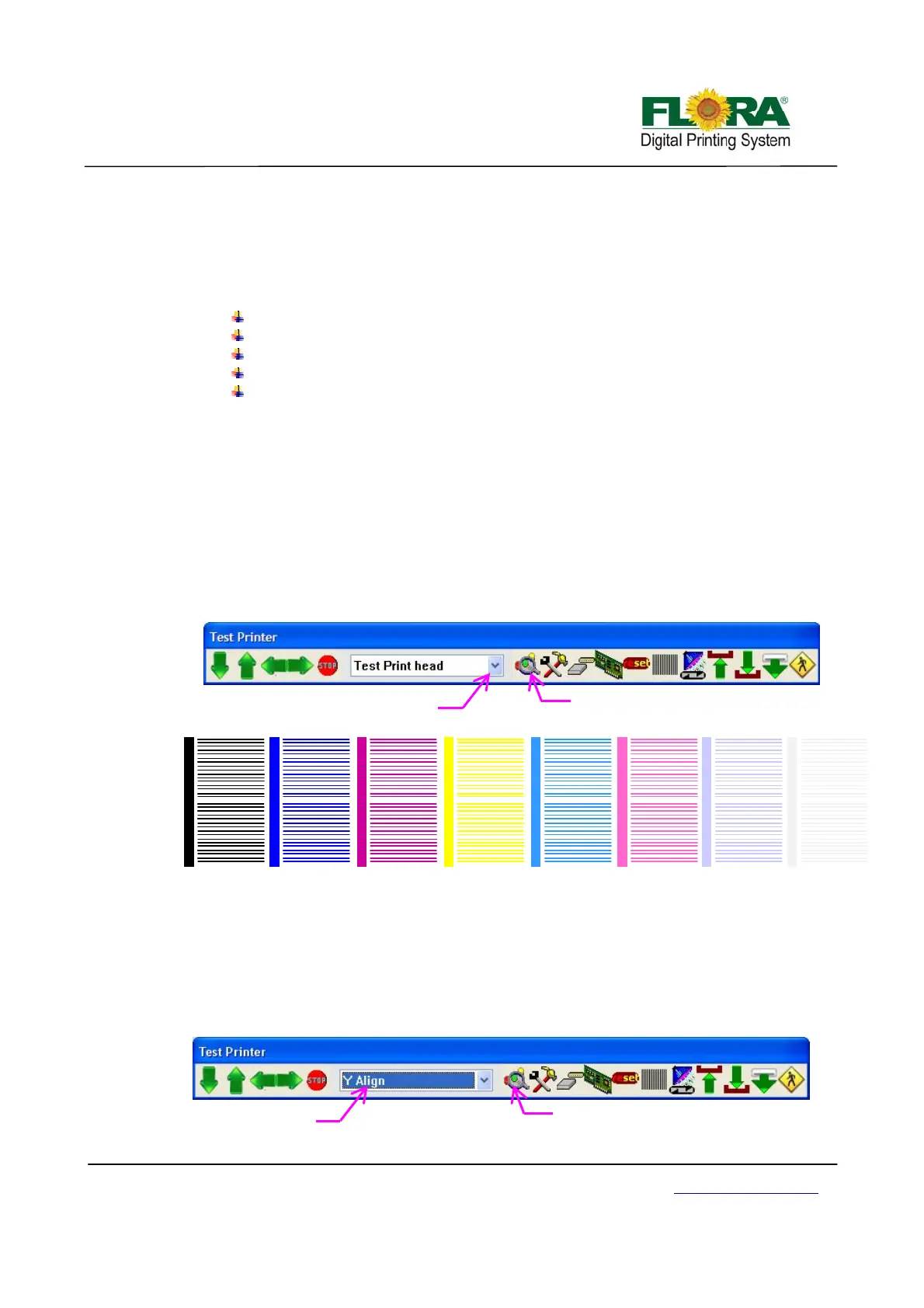

5.5.3.1 Mechanical Alignment (Y-Align)

¾ On Flora driver GUI, click Test Print button and on the Test Printer tab select Y-

align then click “Test print” button. The result should look as shown below.

K1 M1 W1 C1 Y1 V1LC1 LM1

K2 M2 W2 C2 Y2 V2LC2 LM2

Click this to send

test

rint head

Select Test Print Head

Click this to send

test

rint head

Select

-

lign

Loading...

Loading...