Victor Xu Page 72 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

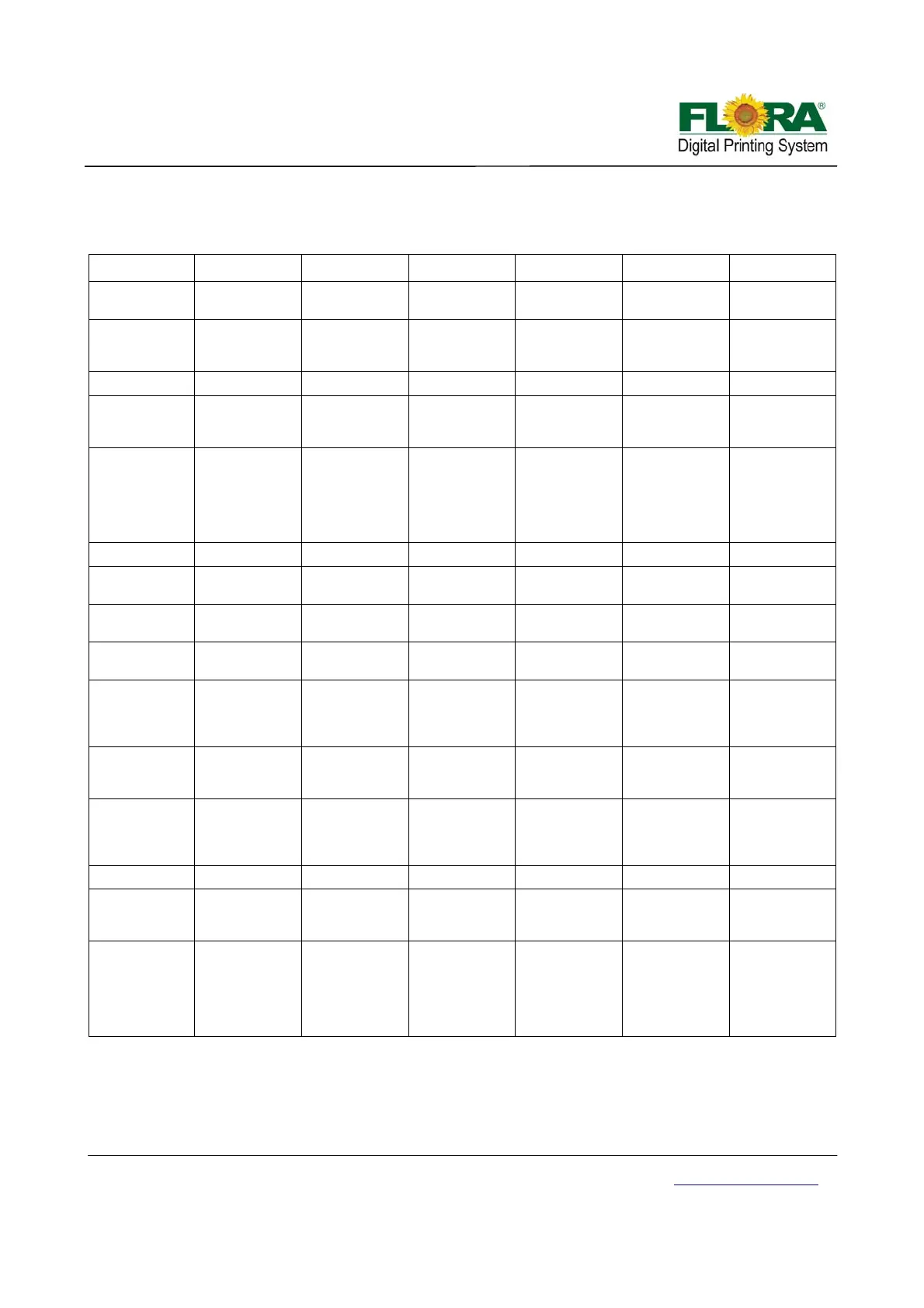

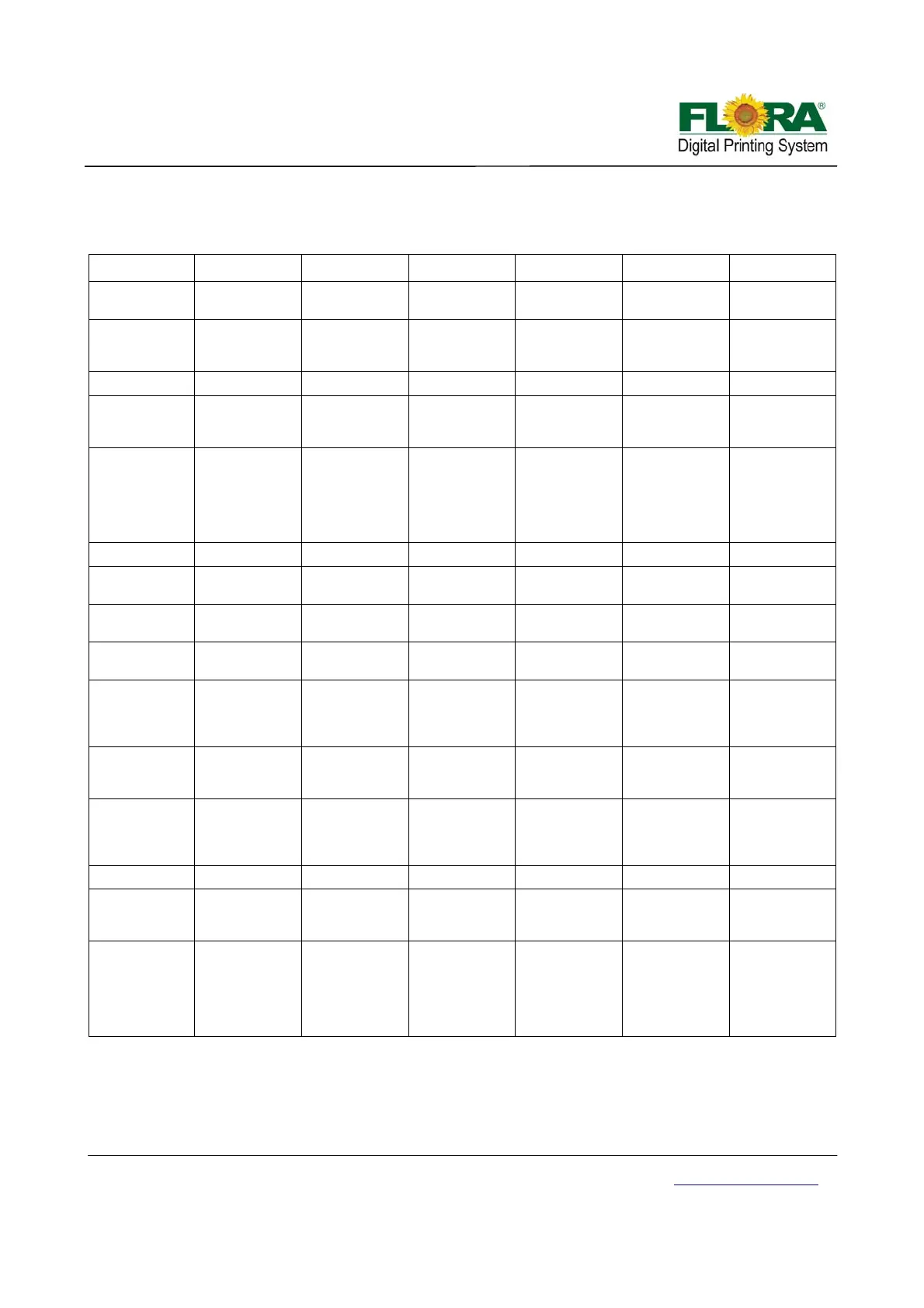

Appendix B Preventive Maintenance Checklist

Item Daily Weekly Monthly Quarterly Semi-annual Annual

Ink Supply Level Check and shake

on startup

Waste Ink Bottle Check for level,

dispose if full or

nearly full

Ink Filters Change

Ink Pumps Check and

replace if

necessary

UV Lamps Check and

change if

necessary, left

UV lamp and

right UV lamp at

the same time

UV Lamp Filters Check and Clean

Flat Bed

Conveyor

Clean

Carriage Linear

Guide Rail

Check, Clean

and Lubricate

Carriage Bearing Check, Clean

and Lubricate

Carriage Belt Check the

tension, adjust

tension if

necessary

Y-feed conveyor

drive gear head

oil

Oil change Oil Change

Vacuum Cleaner

and Filter Bag

Check for waste

ink level and

Clean if

necessary

Change Filter

Bag

Cleaning Station Check and Clean

Raster

Strip/Ruler

Wipe with lint free

cloth before

startup

Automatic

Carriage Height

mechanism

Check if spring is

functional (The

plunger should

return at

up/home

position)

Note: 500 Hrs after installation, the Y-feed conveyor drive gear head oil should be changed.

Loading...

Loading...